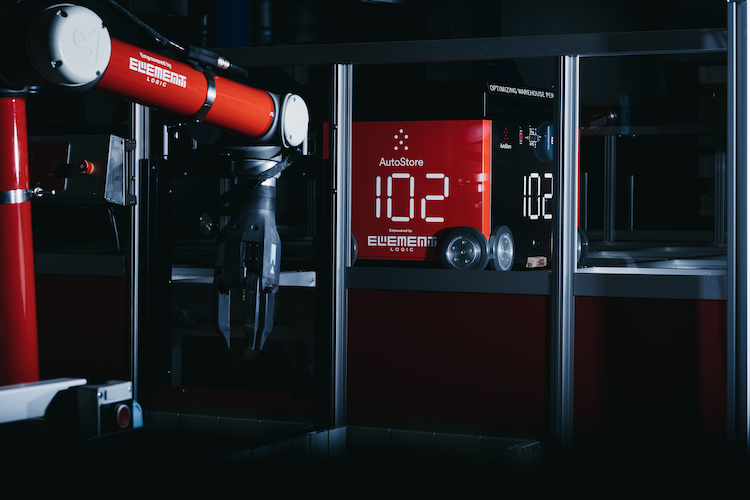

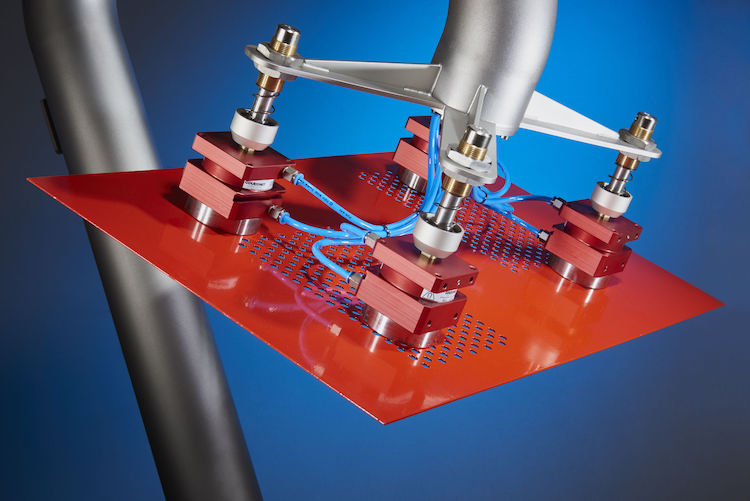

RightHand Robotics has installed a multi-robot picking solution PalTac, which is said to be Japan’s largest wholesaler of consumer packaged goods.

The US company has also established a new corporate entity in Japan, RightHand Robotics GK.

The subsidiary will enable RightHand to better serve the fast-growing demand for robotic piece-picking in Japan and the rest of Asia Pacific. [Read more…] about RightHand Robotics installs robotic picking solution PalTac