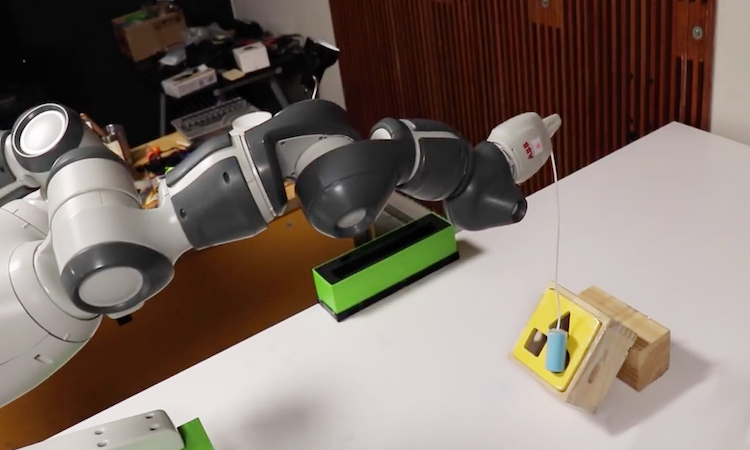

A Taiwanese food and beverage store called Babo Arms is now using a collaborative robot from Universal Robots to make and serve tea.

Universal Robots’ UR5 unit was chosen by Babo Arms to “add a twist of modernity” into their production process.

Babo Arms were searching for an automated device to enhance operations and address the ongoing recruitment issue faced by the food and beverage industry. [Read more…] about Taiwanese store employs robot to make and serve tea