Veo Robotics launches ‘FreeMove’ application development kit

Veo Robotics, a startup which is developing solutions which transform traditional industrial robots into collaborative robots, has launched an application development kit, called “FreeMove”.

Below, we publish a statement released by the company, in which Patrick Sobalvarro, CEO and co-founder, Veo Robotics, talks about the new product and the company.

Readers may also be interested in an interview we recently published on YouTube in which we interview Molly McCarthy, VP business development at Veo.

By Patrick Sobalvarro, CEO and co-founder, Veo Robotics

Veo Robotics builds intelligence and perception for industrial robots so that humans and robots can work together productively, safely, and comfortably in factories.

Now, I’m very happy to announce the availability of our first product, the Veo FreeMove Application Development Kit.

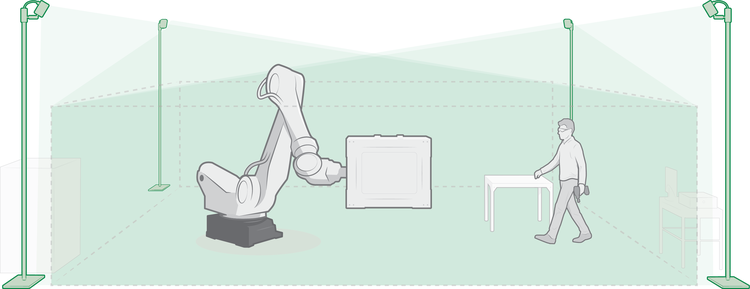

We call it “FreeMove” because it allows production workers to move freely around large robots, and because it gives manufacturing engineers the freedom to design workcells that combine the ingenuity, dexterity, and judgment of human workers with the tirelessness, strength, and repeatability of industrial robots.

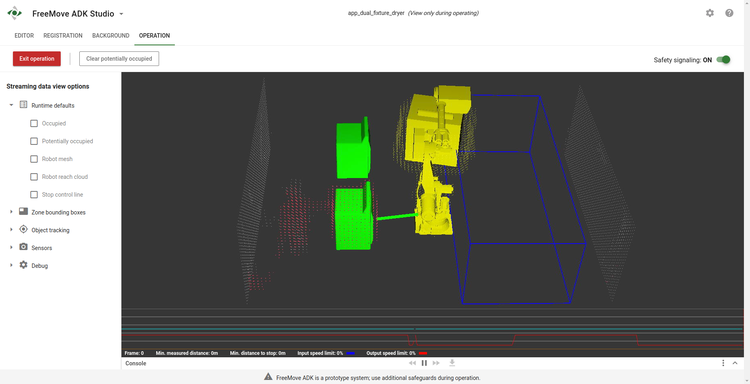

The Veo FreeMove ADK is suitable for use in development environments where automation engineers are developing new process steps for their factory lines. It includes our intelligent vision and control software and our Veo Studio user interface for collaborative workcell setup and configuration.

The FreeMove ADK does not yet include our fail-safe hardware, which will enter beta testing at the end of 2019, and therefore is not intended for use on a production line.

Veo FreeMove makes manufacturing more efficient and productive by reducing both capital and operating expenses. It allows manufacturing engineers to build production workcells that include both robots (or other automatic machinery) and human production workers.

This leads to shorter design times, less custom machinery, and thus less time before the workcell is operational on the line. And in production operations, it enables fluid human-machine interaction, leading to shorter takt times, higher unit production rates, and quicker fault recovery. (The word “takt” refers to the time between starting to work on one unit and starting the next.)

It means no more waiting for maintenance to unlock a workcell to clear a simple fault. Production lines can resume operation quickly and experience less downtime.

We designed Veo FreeMove to be easily installed in one day or less. Our powerful processor, which runs Veo’s intelligent vision software, connects to standard industrial robot controllers over Ethernet and discrete I/O cables.

Simply place the FreeMove 3D time-of-flight sensors at the periphery of your workcell and connect them to the processor, and the Veo Studio software will guide you through camera aiming and registration. Program your industrial robot in its native controller language and continue to use the software development tools you’ve been using – FreeMove will respond accordingly.

The production version of Veo FreeMove will be compliant with the ISO 13849 functional safety standard, meaning you’ll be able to design truly collaborative applications using standard industrial robots.

FreeMove constantly calculates protective separation distances between humans, robots, and any workpieces they may be carrying, and will override the robot program as necessary to safely slow and stop the robot before a production worker can reach it or the workpiece.

Veo FreeMove is the culmination of three years of advanced research and development – we visited over 100 factories and interviewed hundreds of manufacturing engineers.

In the summer of 2018, prototypes of the system were installed at three major manufacturers to test their functioning and the practicality of our approach.

We worked closely with their engineers, gathered feedback, and incorporated it into our development process.

The FreeMove ADK is the product of that work, and while we finalize the development of our production-ready version, you can use the FreeMove ADK to build improved production processes.

Those processes can then be implemented at scale with the full production version of Veo FreeMove in 2020.

Safe, fluid human-machine interaction is the future of manufacturing. It will enable faster product cycles, increased productivity, better uptime, and reduced costs, all with improved ergonomics and safety. We’d love to explore the advantages with you.