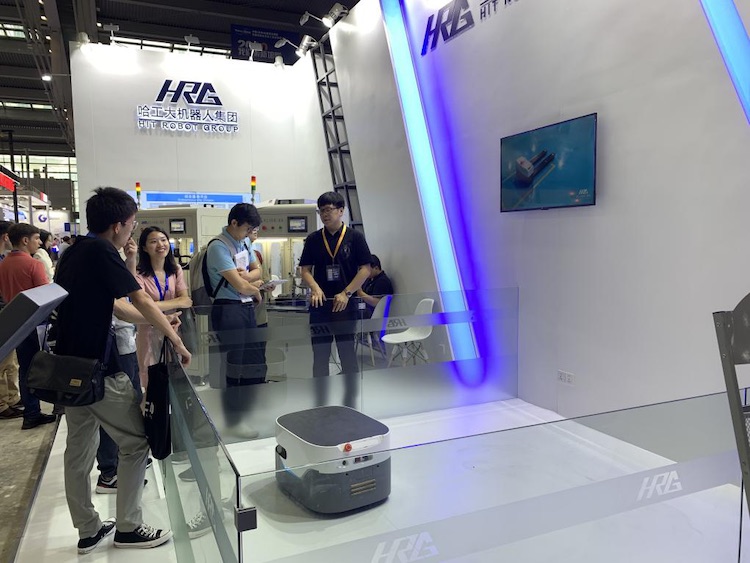

HRG has launched what it describes as an “automated guided vehicle”, although it appears to have the technology that is also found in autonomous mobile robots, which are slightly different.

AGVs are older technology and are limited in their ability to navigate their way round a facility – usually, magnetic strips are fixed to the floor to guide them.

HRG says its AGV integrates “simultaneous localization and mapping”, or SLAM, the navigation technology that gives AMRs their autonomy. [Read more…] about HRG launches new ‘automated guided vehicle’