Audi has been demonstrating its advanced manufacturing technologies, much of which went into building its newly opened smart factory in Mexico, where the automaker’s Q5 vehicle is being produced. [Read more…] about Audi shows off its smart factory technologies

factory

Daimler sets its sights on vision of smart factory

At Daimler, the “smart factory” is the centrepiece of the digitalisation of the entire company. In the smart factory, the products, machines and the entire environment are networked with each other and connected to the internet. Integration of the real world into a functional, digital world enables a so-called “digital twin” to be created, which allows the real-time representation of processes, systems and entire production shops.

“Digitalisation enables us to make our products more individual, and production more efficient and flexible. The challenge is to plan for the long term while remaining able to respond rapidly to customer wishes and market fluctuations,” says Markus Schäfer, executive board member Mercedes-Benz cars production and supply chain management.

“The working environment in the automobile industry is facing major and very rapid changes,” says Michael Brecht, chairman of the Daimler works council. “We want to be actively involved in shaping these changes. One key to this is undoubtedly the systematic, far-sighted training of the current and future workforce.” [Read more…] about Daimler sets its sights on vision of smart factory

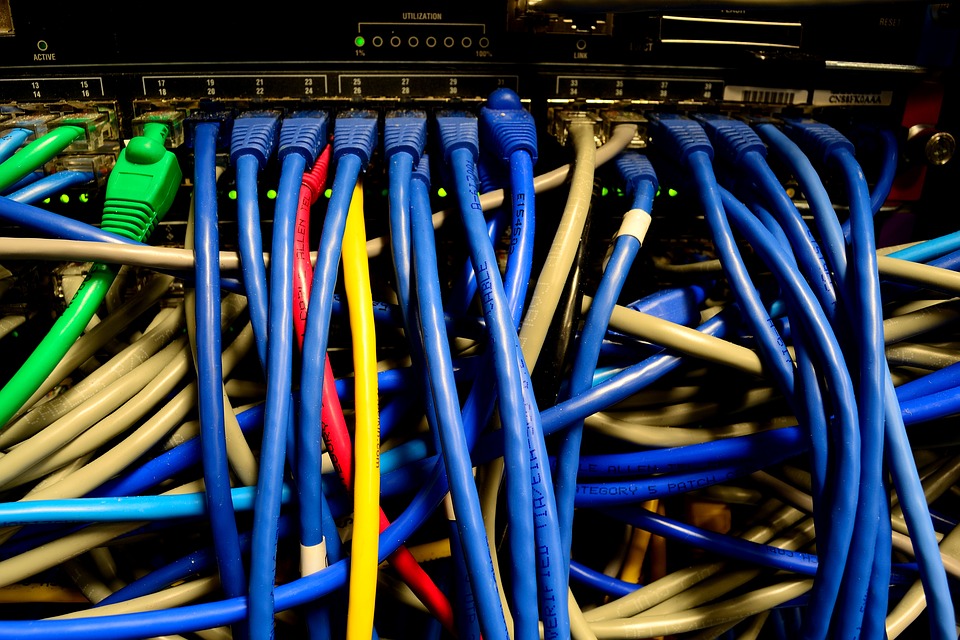

Connected world: The death of proprietary networks

Jonathan Wilkins, marketing director of EU Automation, takes a look at one of the casualties of fluid communication in the factory – that is, the death of proprietary networks and communication protocols in favour of the uninhibited free flow of data

Like it or not, we live in modern world of fluidity and interconnectedness in which the once ordinary now transcends all previous boundaries.

Take the humble kettle for instance. It’s a sign of the times that you can now purchase a kettle you can control from your phone via the internet. It will even send you notifications when it needs filling or if it’s at optimum temperature. Because it was hard to tell before.

Joking aside, one place where interconnectivity really is making a difference is on the factory floor. [Read more…] about Connected world: The death of proprietary networks

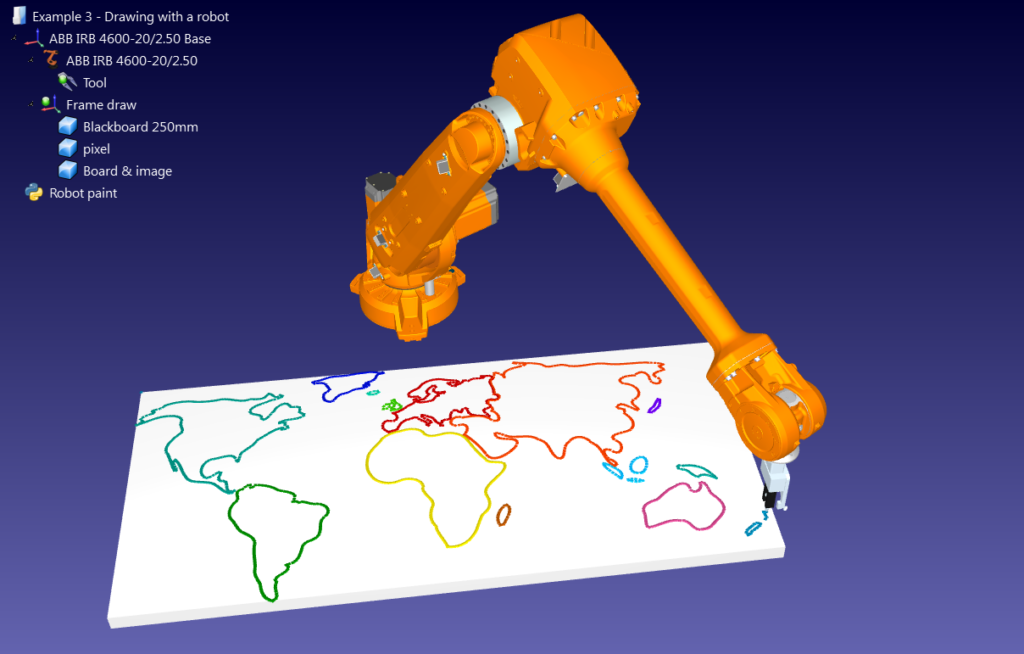

RoboDK updates industrial robot simulation application

RoboDK has launched the latest version of its industrial robot simulation application.

The company’s CEO, Albert Nubiola, says the software is now much faster and easier to learn and use.

He adds that RoboDK is working on producing more video tutorials and manuals. “RoboDK has been updated to better integrate into smart factories and Industry 4.0 networks.

“The RoboDK software enables your robots and your factory to automatically adjust processes according to any modifications, as well as accurately merge the virtual simulation with the physical world.”

Robots are positively impacting our world, says Aethon

By Anthony Melanson, vice president of marketing, Aethon

Robotics headlines are everywhere: “China’s Impending Robot Revolution”, “IFR Report Offers Good News for Robot Developers,” and “Can Robotics Spark a Renaissance in American Manufacturing”.

There’s little question that self-driving robots, drones and other automated vehicles are integral to the present and future success of organizations in a wide-variety of sectors.

Self-driving cars are on a tremendous innovation curve and it will be exciting to see them develop. From healthcare to industrial material handling, robots are positively impacting our world. [Read more…] about Robots are positively impacting our world, says Aethon

Nasa scientist behind Reebok’s new ‘Liquid Factory’

Sportswear giant reveals new technique – invented by a Nasa scientist – for 3D printing training shoes tailored to customers’ individual specifications

Reebok has unveiled something it calls “Liquid Factory”, which the company says will bring back sports shoe manufacturing back to the US.

Reebok calls its new factory idea a ground-breaking manufacturing innovation that could fundamentally change the process and speed of footwear creation.

Developed by the Reebok Future team, the Liquid Factory process uses state-of-the-art software and robotics to literally draw shoes in three dimensions. [Read more…] about Nasa scientist behind Reebok’s new ‘Liquid Factory’

Faurecia launches $64 million smart factory in Columbus, Indiana

Faurecia has unveiled a $64 million “digital factory”, or smart factory as some call it, which the company says showcases the future of manufacturing.

Faurecia says the Columbus, Indiana-based emissions control technologies plant represents the industrial giant’s digital transformation.

Faurecia, which is a leading automotive technology supplier, says the $64 million Columbus South plant is a “data-driven manufacturing facility”. [Read more…] about Faurecia launches $64 million smart factory in Columbus, Indiana

Rethink Robotics’ Sawyer signs deal with Korean company TPC Mechatronics

Rethink Robotics has reached a deal with a South Korean pneumatic equipment manufacturer and distributor.

TPC Mechatronics will utilise Sawyer collaborative robots from Rethink Robotics in its own facility, as well as the facilities of its customers, in “an effort to move the entire industry toward smarter factories”, according to the companies.

The exclusive distribution partner of Rethink Robotics in Korea, TPC Mechatronics’ core customer base consists of a wide range of industrial manufacturers. [Read more…] about Rethink Robotics’ Sawyer signs deal with Korean company TPC Mechatronics

Manufacturing: Smarter than the average factory

What’s all this talk about “smart factories”? It’s just a bunch of machines being connected to the internet, right? What’s the big deal? What’s the big idea?

True, it’s all about connectivity. But that is, in fact, a very big deal – lots of very big deals, lots of very small deals, just lots and lots of deals, which, when combined, is indeed a huge, historic shift in industrial production, encapsulated by some in terms such as “Industry 4.0” or “Industrial Internet”.

Having been articulated, arguably, by the Germans, talk about “the fourth industrial revolution” or “Industrie 4.0” has permeated virtually all conversations about the future of manufacturing. [Read more…] about Manufacturing: Smarter than the average factory

Industrial internet: 42Q launches new protocol capability for factory automation

42Q, a provider of cloud manufacturing execution systems (MES), has introduced Semiconductor Equipment Communications Standard, Generic Equipment Model (SECS/GEM) protocol capability.

SECS/GEM is an industry standard factory equipment interface protocol for equipment-to-host data communications.

In securing SECS/GEM capability, 42Q says it greatly simplifies the implementation of factory automation, machine to machine (M2M) communication, real time in process data collection and data analytics, all key elements of Industry 4.0 and the Industrial Internet of Things (IIoT).

Several factories using 42Q have already deployed this new protocol in their operations, sasy the company. [Read more…] about Industrial internet: 42Q launches new protocol capability for factory automation