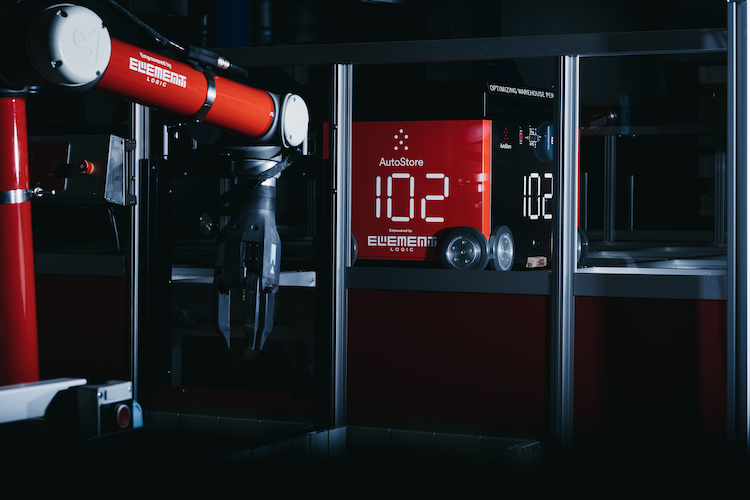

RightHand Robotics, a provider of warehouse automation technology, and Element Logic, an AutoStore partner, have launched an integrated robotic piece-picking solution that combines the technologies of both companies.

The announcement was made in conjunction with IMHX in Birmingham, UK, September 24-27.

The robotic piece-picking solution combines award-winning technology from RightHand Robotics with Element Logic software and AutoStore’s automated storage and retrieval system. [Read more…] about RightHand Robotics and Element Logic launch integrated robotic piece-picking solution