Locus Robotics has become one of the defining companies in warehouse automation, best known for its autonomous mobile robots (AMRs) that work alongside people in logistics centers around the world.

But increasingly, the company’s real differentiator may lie not in the hardware itself – which many would argue has reached near-optimal design for its purpose – but in the intelligence that drives it.

Hamid Montazeri, senior vice president of software and AI at Locus Robotics, leads the team responsible for that intelligence. His work focuses on developing what he calls “physical AI” – domain-specific artificial intelligence designed to operate in the unpredictable, fast-moving environment of a warehouse.

It is this software layer, Montazeri argues, that transforms mobile robots from efficient movers of goods into adaptive, collaborative systems capable of reasoning about the physical world in real time.

The debate over where the next wave of innovation will come from in robotics – hardware or software – is an ongoing one.

Many roboticists believe the physical machines have matured to the point of diminishing returns: they are already fast, safe, and reliable.

Others see the frontier shifting toward advanced perception, coordination, and learning – areas driven largely by AI and data.

Montazeri sits firmly in the latter camp, describing a future where software innovation unlocks the next level of performance and scalability for autonomous fleets.

In this Q&A, Montazeri explains why humanoid robots are unlikely to solve warehouse labor shortages any time soon, and why domain-specific AI – purpose-built for logistics – offers a faster, more cost-effective path to automation.

He discusses the growing importance of “physical AI”, how investment strategies in robotics are changing as we head toward 2026, and what technological breakthroughs he believes will reshape the fulfillment industry over the next few years.

Interview with Hamid Montazeri, SVP of Software & AI at Locus Robotics

Robotics & Automation News: Humanoids vs. warehouse AI – You’ve said humanoid robots won’t solve warehouse labor gaps. Can you explain why, and what makes domain-specific AI a more practical solution for logistics today?

Humanoid robots might represent a long-term vision for automation, but they’re not equipped to solve the immediate labor gaps in today’s warehouses. The ROI just isn’t there yet, in terms of both cost and capability.

What’s delivering real value right now is domain-specific physical AI systems, particularly in the form of Autonomous Mobile Robots (AMRs).

Unlike general-purpose robots, AMR systems are purpose-built with specific abilities in mind, such as effectiveness in a warehouse environment.

AMRs, equipped with domain-specific models, adapt quickly to changing workflows and environmental changes, optimize productivity and scale efficiently.

Modern AMRs leverage physical AI to operate intelligently in real-world warehouse conditions. For companies facing acute labor shortages and supply chain pressures, the fastest and smartest path forward is through targeted, high-impact automation.

R&AN: Physical AI in action – How do you define “physical AI,” and can you share an example of how it’s already transforming warehouse operations in terms of efficiency, resilience, or adaptability?

Physical AI is what separates next-gen warehouse automation from legacy systems. Physical AI involves the integration of advanced sensors, real-time sensor data fusion, intelligent adaptive decision-making, and electro-mechanical actuators, often in an AMR format, that allows systems to perceive their environment and interact with that environment to accomplish highly needed goals and tasks.

Modern approaches to physical AI often include a domain-specific set of AI models embedded within the robotic systems to perform highly specialized tasks in real-world environments.

In the warehouse, that means using AI not just to process data, but to take physical action – whether it’s picking items through vision-based manipulation, identifying and classifying SKUs, or adapting in real-time to shifting workflows.

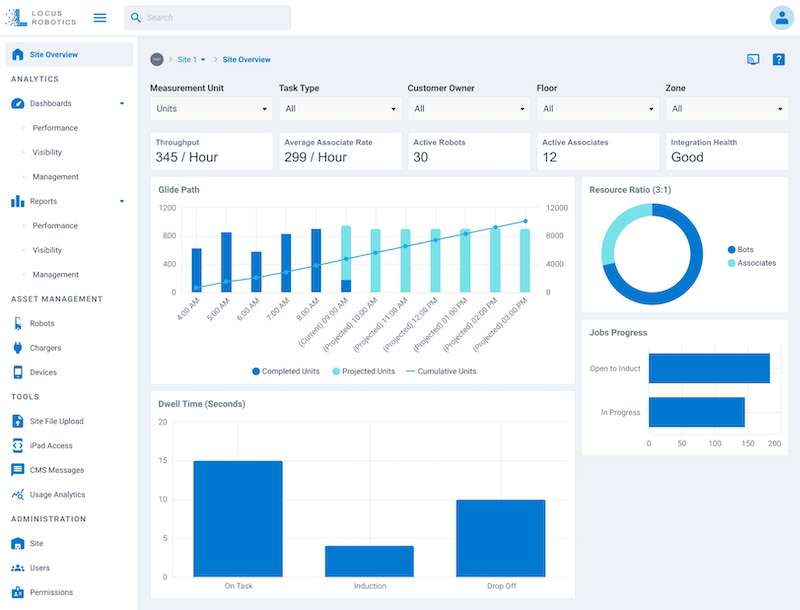

These models are trained on real-world warehouse operational data and built to scale across fleets. AMRs are using physical AI within the warehouse to continually optimize routes, avoid obstacles and seamlessly integrate with business workflows.

This has already led to significant gains in efficiency, resilience and adaptability, especially in high-volume, high-velocity environments.

R&AN: Domain-specific models – What are the key advantages of domain-specific AI models over generic foundation models in the context of robotics for supply chain and fulfillment?

Domain-specific AI delivers clear advantages over generic foundational models. These purpose-built models are trained to solve highly specific business problems with greater accuracy and repeatability, whether it’s improving pick accuracy, optimizing throughput, creating adaptive travel paths for AMRs or responding to bottlenecks and congestion areas in real time.

Because they’re trained directly on domain-specific operational goals, these models generate faster ROI and are far more cost-effective to deploy.

Unlike generalized systems, which can be expensive and difficult to scale, AMRs enhanced with domain-specific models are comparatively affordable to deploy and offer immediate, measurable benefits.

R&AN: Investment strategies – From your perspective, how are robotics and AI investment strategies evolving in supply chain automation as we head into 2026?

We’re seeing a fundamental shift in how companies approach robotics and AI investments in areas such as warehouse automation.

Persistent labor shortages, coupled with shifting global trade policies, are pushing organizations to prioritize automation as a strategic imperative rather than a nice-to-have.

They are now investing in automation as a long-term strategy for resilience and agility. AMRs are at the center of this shift, as they deliver fast deployment, clear ROI and the ability to adapt in real time to changing conditions.

In the warehouse automation world, AMRs are designed to meet the specific demands of fulfillment operations, making them easier to scale and align with business goals. The companies that are winning in this space aren’t just automating; they’re building more agile, future-proof supply chains.

R&AN: The future of fulfillment – Looking ahead, what do you see as the biggest breakthroughs that will reshape warehouse operations over the next three to five years, and how is Locus Robotics preparing for them?

One of the biggest breakthroughs we expect to reshape warehouse automation over the next three to five years is the advancement of smart sensors, sophisticated data fusion capabilities, and advances in physical AI that will allow fielding of even more capable AMRs.

The next-generation smart sensors will dramatically improve an AMR’s ability to perceive its environment with greater precision and less noise. When combined with modern AI developments, AMRs will grow in their versatility and will be able to accomplish an ever-increasing set of tasks that henceforth required human involvement.

As AMR capabilities continue to evolve, we’ll see fulfillment operations become not only faster but also significantly more efficient, adaptable and intelligent.