Manufacturing Software: Definition and Benefits for Your Business

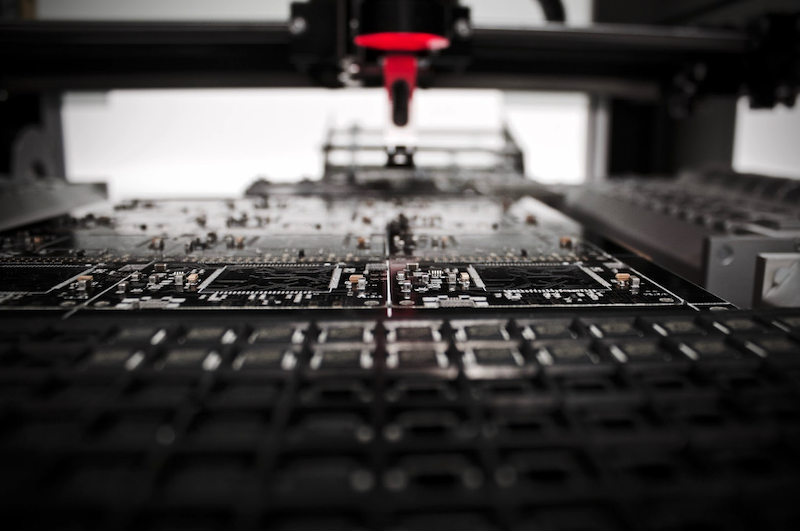

Today, IT solutions are just as necessary as the machinery and heavy equipment used to produce products. As such, it is used by large and new small and medium manufacturing companies.

This software is also designed for those who have factory businesses such as import/export trade. Manufacturing IT solutions are designed to streamline a manufacturer’s operations, from supply chain management to distribution management, increase organizational productivity, and reduce operating costs.

Manufacturing software is a tool that provides functionality to plan and execute projects from beginning to end while automating materials planning, production tracking, and scheduling and product lifecycle management.

Benefits of Manufacturing Software for Businesses

- Streamline Processes: With ERP software, you can automate and streamline processes to improve your entire department’s overall efficiency and productivity.

- Reduce Costs: Manufacturing software provides a comprehensive view of administration, leading to cost efficiency. Not only do the time and resources saved collecting this information from multiple systems save your business, but it also benefits from less waste, improved processes, and satisfied customers.

- Managing Cash Flow: Consistent and reliable cash flow is critical to most businesses. An integrated ERP solution can help you manage your cash flow and minimize development risks. When all transactions are logged, you have a detailed log of what is sent and what is received.

- Deliver Accurate Data and Improve Decision-Making: Manufacturing software enables manufacturers to obtain estimation accuracy by supplying data on all aspects of their business operations. For example, sales performance, customers, profit and loss, inventory, finance, labor, and so on. All the generated data helps stakeholders create more accurate estimates and effective forecasts, enabling management to act smarter and faster. Business making decisions.

- Production Monitoring Across Multiple Sites Made Easy: With Advanced Manufacturing Software, manufacturers can monitor production processes across multiple manufacturing sites in terms of duration, the number of employees involved, costs incurred, materials used, and product life cycle, and can be monitored by internal and external transfers. As a result, cloud-based manufacturing systems help manufacturers inspect processes from anywhere with their mobile devices.

- Improving Product Quality: Manufacturing software not only speeds up a company’s production process but can also enhance the quality of the product by helping companies monitor product defects and problems.

- Reduce Unprofitable Processes: Manufacturer software can also identify bottlenecks early and identify profitable and unprofitable strategies for the enterprise. By eliminating unprofitable businesses, manufacturers can focus on improving the quality of their products and services.

Main Features of Manufacturing Software

- Manufacturing software plan: Manufacturers can easily manage their production activities through the features of the software plan.

- Making software orders: This feature helps determine the manufacturer’s number of goods produced. They can select the material needed, the person in charge, and the production route.

- Work order: This feature makes it easy for the manufacturer to determine and record various needs to continue the work in the process of production.

- Work center: Manufacturing companies can use codes to perform their manufacturing activities and create work centers or organizational units with the help of this feature.

- Bill of materials (BOM): It is a list containing all materials and components required for production. It also includes their cost and quantity. With this bill of material feature, manufacturers can calculate the needed material and production costs.

- Route: It is a process in which the producer can arrange the step needed to produce finished goods. They can determine the work center and the duration required for each production stage through manufacturing software.

- Reporting: The manufacturing software can obtain complete reports of the manufacturing system.

Solutions for Manufacturing that Optimize Your Business Productivity

- ERP solutions: A custom ERP is designed to provide bespoke functionality to meet your company’s unique operational and strategic needs. Besides introducing certain features that are not provided by various ERP tools on the market, a custom ERP has the following advantages:

- Seamless, cost-effective integration with any system you need, including legacy software.

- Pleasant UX and clear user interface for different user roles.

- Compliance with all required global, national, and industry regulations. Security of

- Toplight ERP software and data stored in it.

- Support for centralized or decentralized (blockchain-based) data storage.

- Long-term optimized TCO.

- Business intelligence solutions: Business intelligence (BI) solutions are designed to acquire, process, analyze, and report on data to make informed business decisions. Key features of BI solutions are multiple data source integration, AI-driven data preparation and analysis, controlled data access, scheduled ad-hoc reporting, and interactive visualization.

- Data warehouse solutions: Data warehousing (DWH) services include consulting, implementation, support, migration, and managed services to help your enterprise reap the benefits of a powerful DWH.

Faster and more efficient

To summarize, manufacturing is often called a factory. Manufacturing is an industry that produces goods and services. Manufacturing processes must become faster and more efficient to meet production requirements. One of the actions that can be taken to enchant productivity and maximize profit is to use manufacturing software.