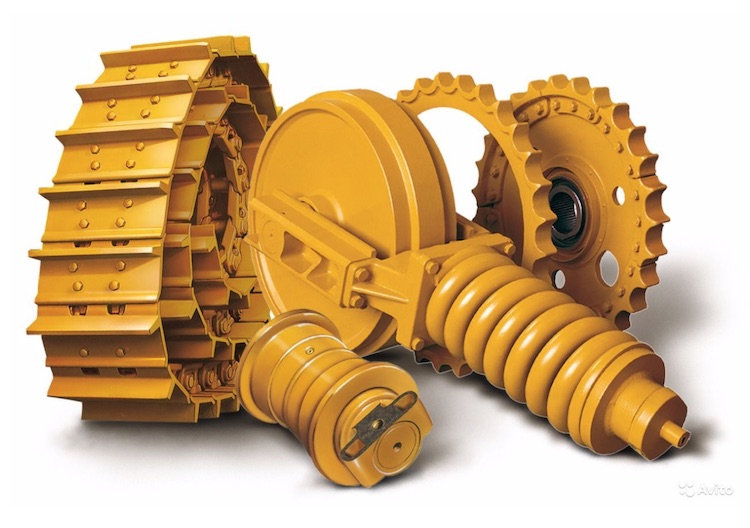

Maintenance Tips for Komatsu Undercarriage

Every vehicle operator would prefer an undercarriage to last forever, but it is impossible.

Wear may not be prevented.

However, with a reasonable approach to maintenance, your costs will be minimized. Here are a few tips to help prolong the lifespan of your auto parts.

Sooner or later, your undercarriage will need to be replaced. For such cases, the Komatsu parts catalog on epcatalogs.com is helpful. Bear in mind that replacement can be costly.

To extend the life of undercarriage elements, follow the recommendations below. It is always cheaper to take precautions.

1. Cleaning

The tracks on your vehicle must be as clean as possible – a high-pressure hose should be used frequently. This way, they are likely to pack or build up with ground products like dust or dirt.

As a consequence, wear will intensify, power will decrease, and fuel consumption will go up. Do the cleaning before or after each shift. This need may not be overlooked.

2. Adjustment of Tracks

Making sure the tracks are kept to the right adjustment is a must. You will need to use the Komatsu Operation & Maintenance Manual. The document for your vehicle will give you the exact adjustment and provide ways of achieving it.

3. Make Reversing Rare

In general, the forward movement always causes less wear on your tracks than the opposite. Therefore, it is only reasonable to resort to reverse when it is absolutely unavoidable. Also, the power necessary for reverse travel will drive fuel consumption up.

4. Operating Conditions

If you use your vehicle in any tough conditions, the wear will accumulate faster. In the case of abrasive materials in a wet environment, the effects will be observed soon.

However, if you monitor the undercarriage and take action when necessary, you could extend its lifespan.

Previously, vehicle operators would simply wait for the undercarriage to get completely worn and have the links replaced.

Today, it is different: scheduled inspections are a must, and you should also turn the bushes and pins through a 180-degree angle.

5. Correct and Regular Measurements

Have a Komatsu Product Support Representative (PSR) regularly inspect the condition of the undercarriage components. This should happen at least twice a year. The company’s e-Care undercarriage inspection service is rendered for free.

The conclusions drawn by the PSR will help prolong the life of components and hence minimize any replacement costs. The inspection will include several vital elements. Here are the main things to consider:

- sprocket ring replacement;

- roller rotation; and

- pin and bush turns.

The latter may add as much as 60 percent of life to your tracks. Bear in mind that wear on these parts is measured in millimeters. Hence, the visual inspection does not suffice. You have to be using the necessary tools.

Here is a simple example: at 5,000 hours, conducting a pin-and-bush turn could get you 3,000 to 4,000 additional hours. Otherwise, the total is unlikely to exceed 7,000 hours.

Take care of the state of your undercarriage and get rewarded with its longer lifespan.

Promoted