Robot cell guarding: When adaptability trumps strength

Luke Wilkinson, design and product development manager at Matara, looks at the growing use of aluminium over steel in robot guard frames and the reasons behind its rising popularity

It is estimated that there are around 23,000 robots operating in industrial settings in the UK. The automotive sector is the largest user employing over 9,000, with the food and drink sector recently rising to second place.

With their ability to perform repetitive tasks accurately, swiftly and consistently, it’s not hard to understand why the use of robots across industry is growing. A survey conducted by the British Automation & Robot Association showed sales of robots in the UK to be 7.5% higher in 2020 from the previous year.

Whilst the benefits of using robots in industrial settings are clear, it’s important to take into account the potential safety risk they pose; not of a science fiction nature, but a very real, present in the here and now type risk that primarily stems from people accidentally getting in their way which can have serious consequences if the machine is fast moving, carrying a heavy payload and so on.

Less likely, but still hazardous, the robot could malfunction causing a change in its actions which could have safety repercussions for anyone within the immediate vicinity.

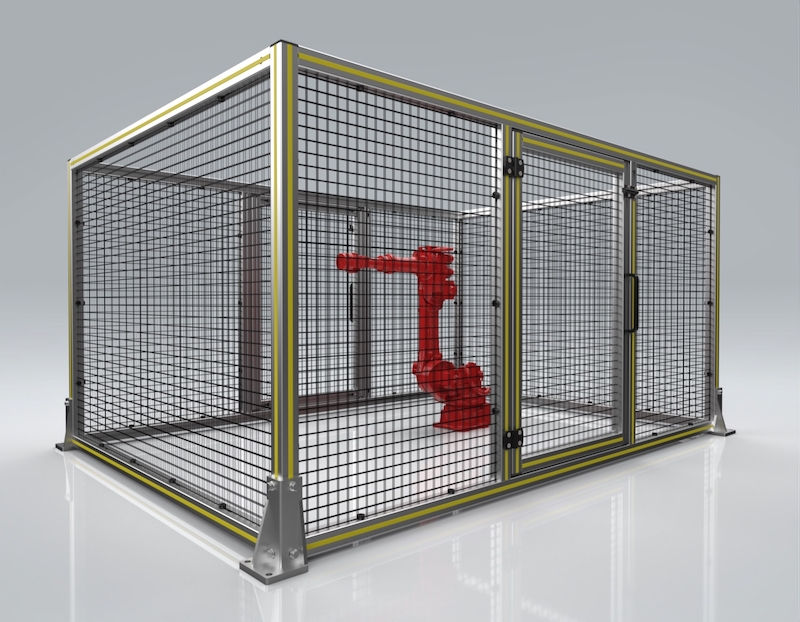

As a result, the robot needs to have a safety guard around its perimeter. There are various methods for doing this, including high tech (and high price) methods such as roller shutter doors integrated with a vision system, but the simplest method is frequently the most effective: a physical guard frame.

Building a sturdy metal frame around the robot stops people from accidentally passing too close to it. It can be easily seen and therefore avoided and, if built to the correct standard, can easily withstand a person falling against it. It’s a simple, low tech, cost effective solution for a high tech piece of machinery.

The automatic go-to-choice of material for a protective frame of this nature has been steel box section. Steel is strong and its familiar. But steel has a number of drawbacks in this application which is leading people to look to aluminium as an alternative.

Time and cost Implications

Focussing on the machining aspect, you can clearly see what difference your choice of metal will make to the overall cost of the guard system. With steel, you have to weld all the component parts together.

If you want to add accessories of any sort, you have to drill a series of holes, tap out the holes to put a thread on it, and then screw the accessory into that thread. Get it wrong, and you have serious issues – some of which can’t be easily remedied – and cost implications.

For example, what if there was a mistake in one of the measurements supplied to the manufacturer? If the error only comes to light after the guard cell has been produced and is being put together on site, there’s very little you can do to alter it if you’re working in steel.

Depending on the size of the box section, you may require specialist equipment, such as a plasma cutter, to cut it; not only is that going to add to the cost, but it will also cause delay as it’s unlikely a plasma cutter is to be found close at hand. If this was aluminium, on the other hand, a simple Mitre saw or similar tool would do the job without any major effort or cost.

With aluminium, there’s no welding or drilling. The frames can be connected together with an Allen key and adding accessories couldn’t be simpler as aluminium profiles use T slots pre formed into the material and all accessories simply slide into these.

This can save hours and hours of work, enabling virtually anything you need, including vision systems, to be dropped into the back of the T slot and fixed in place, as opposed to standing there with a drill, trying to drill holes into steel precisely where they are required.

The modular nature of an aluminium profile also makes it easy to install safety systems, such as non-contact safety switches that will stop the machine running if the door opens.

So, the cost implications of working with steel versus aluminium are clear, but it’s also a time issue. It’s considerably quicker to produce a guard made up of aluminium; an entire robot guard system can be manufactured in less than a week. The equivalent in steel would take much longer.

Convenience

Once the guarding system is manufactured, it’s delivered to site either as the completed structure or in sections for assembly on site, which brings a further set of challenges that many companies may not have factored in.

Delivering the guarding system in one final piece can be logistically challenging, especially if it’s a large one. Specialist transport may be required and then there’s the issue of getting it in place on site without damaging anything. With a steel system this is all the more problematic when you factor in the weight; specialist lifting equipment might be required for offloading.

On site assembly is frequently a more appealing option, but only when it comes to aluminium systems. If you opt for an aluminium guard system, it can be delivered to site in easy to manage plates and swiftly connected together with something as straightforward as an Allen key. One person can assemble an entire frame on their own with no mess and no fuss.

With a steel system, if it’s delivered to site in sections it will need to be welded together on site. That takes longer, is energy intensive and introduces a level of risk that needs to be managed. In our experience, few companies are happy with on-site welding of this nature so instead the guarding unit is delivered as a whole, finished structure which, as we have already seen, can be very expensive and logistically complicated.

Adaptability

Time and cost savings go hand in hand with adaptability when it comes to choosing aluminium profiles.

As I’ve highlighted above, steel is difficult and expensive to work with, which also makes modifications tricky. With steel, to make changes to the guard could take several days to cut an old part out and weld in a new section and drill any holes required.

With aluminium, using an Allen key, you loosen the connectors, slide the old one out and slide the new one in. It’s not only quick but it’s also completely reversible. So, if a week from now you decide you want to take something out, you can – there’s nothing stopping you; with steel, it’s permanent.

Furthermore, aluminium systems are available with a wide range of off the shelf accessories to suit the T slots, such as hinges, simple sliding mechanisms, handles etc, that allow for an even greater degree of flexibility when designing the system or modifying it at a later date.

Final Word

I have put the case for considering aluminium profiles in robot cell guarding, but whichever option you choose – aluminium or steel – there is one key piece of advice I’d like to impart. The perimeter robot guard is a fundamental part of the overall system and should not be left to the last minute. It is, after all, a crucial safety system that could save someone’s life.