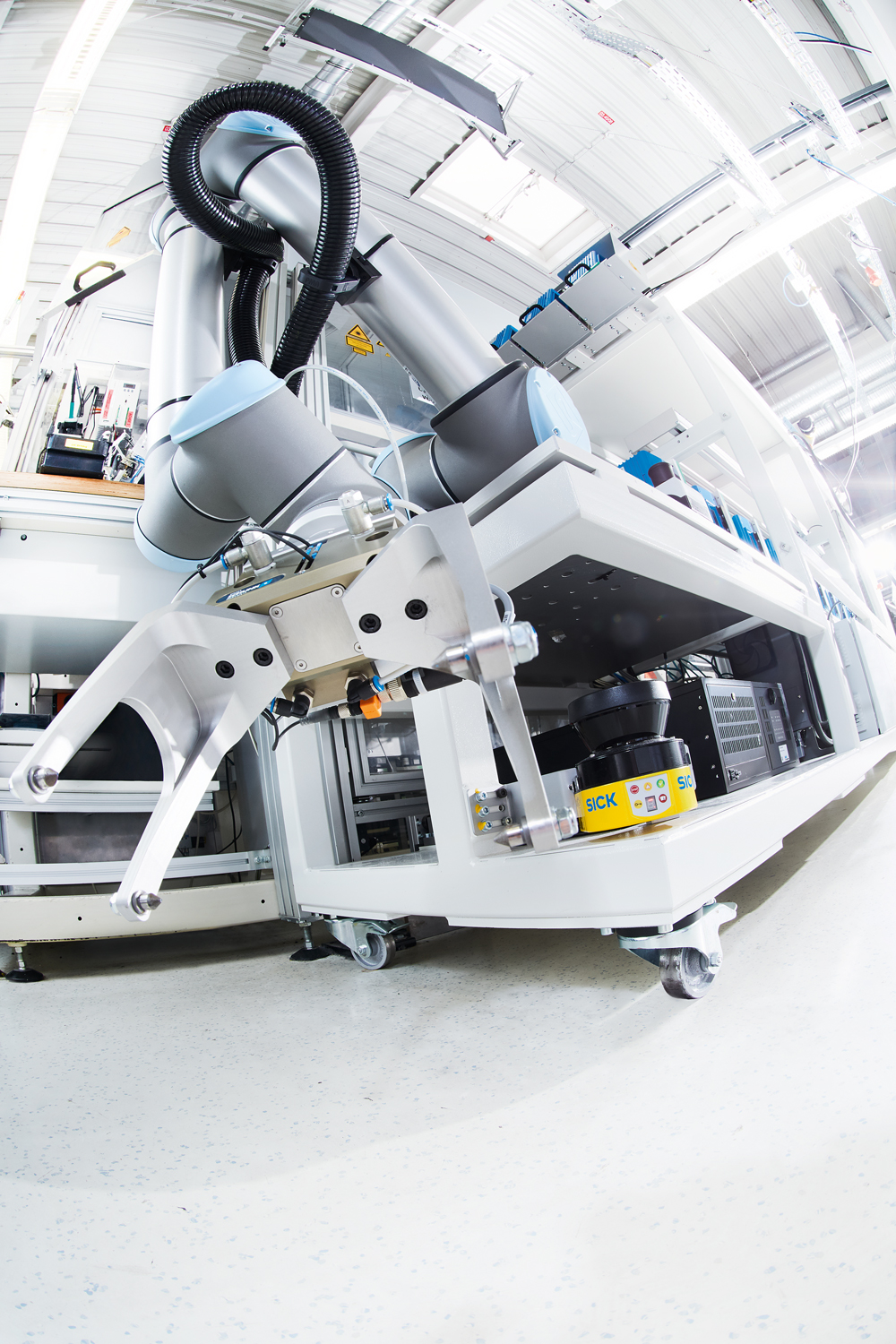

SICK is unveiling indoor localization technology which lets users know where all their machines are at all times.

The sensor supplier is planning to showcase the system at the Pack Expo Las Vegas later this month.

SICK says it has taken another step toward Industry 4.0 by offering a new, comprehensive indoor localization portfolio.

With coordinated sensors and analysis tools, large amounts of data can now be evaluated purposefully and fields of action can be displayed in factory processes or logistics.

Indoor localization makes it possible to manage complex networks, create transparency, and ensure speedy production.

SICK says it is the first manufacturer to offer a comprehensive range of solutions along the entire value creation change from a single source.

SICK has many years of experience and is recognized as a market leader in the area of object tracking on conveying systems.

Read rates for bar codes or RFID at stationary read locations determine the performance of the system.

Localization solution from a single source

Assets in a factory can be tracked continuously using localization solutions – known as indoor GPS – and their space-time coordinates can be continuously recorded and stored.

Having this data means complete transparency about all the important movements on the shop floor.

Today’s analytics tools can already use this data to make connections between different events, presenting an unfiltered look into actual factory or logistics processes.

All the established technologies – ultra wide-band tags, LiDAR Contour Mapping, line guidance sensors, infrastructure sensors – record either their own position or the position of the desired objects.

Depending on the application as well as the positioning accuracy and update rate required, the right technology is selected or various technologies are combined with each other.

SICK claims to be the first manufacturer to offer all technologies for individual customer applications. SICK says it can cover the entire solution scope from sensors to the cloud-hosted smart data service.

The customer gets everything it needs for smooth operation – from the consultation to the service level agreement – from a single source.

Industry 4.0 is happening now

Localization technology is one of the key factors in achieving the type of networked production and logistics needed for Industry 4.0.

It can be used to boost optimization potential in several areas by allowing for agile planning of production and logistics processes.

Localization data gives companies a high level of transparency and understanding of all production-related assets, load carriers and loading equipment.

The payoff: Travel paths can be optimized and adapted dynamically. Setup times can be prepared or scheduled flexibly.

The material flow can be planned and controlled based on consumption. All of this boosts delivery quality and on-time delivery. And everything is fully automated.

At PackExpo 2019, SICK is providing an in-depth look at the company’s approach to analytics, deep learning, and localization in its booth, where experts will give talks about the future of Industry 4.0 at Booth #LS-6419.