A Look at Liquid Cooling Solutions for Data Centers

February 13, 2024

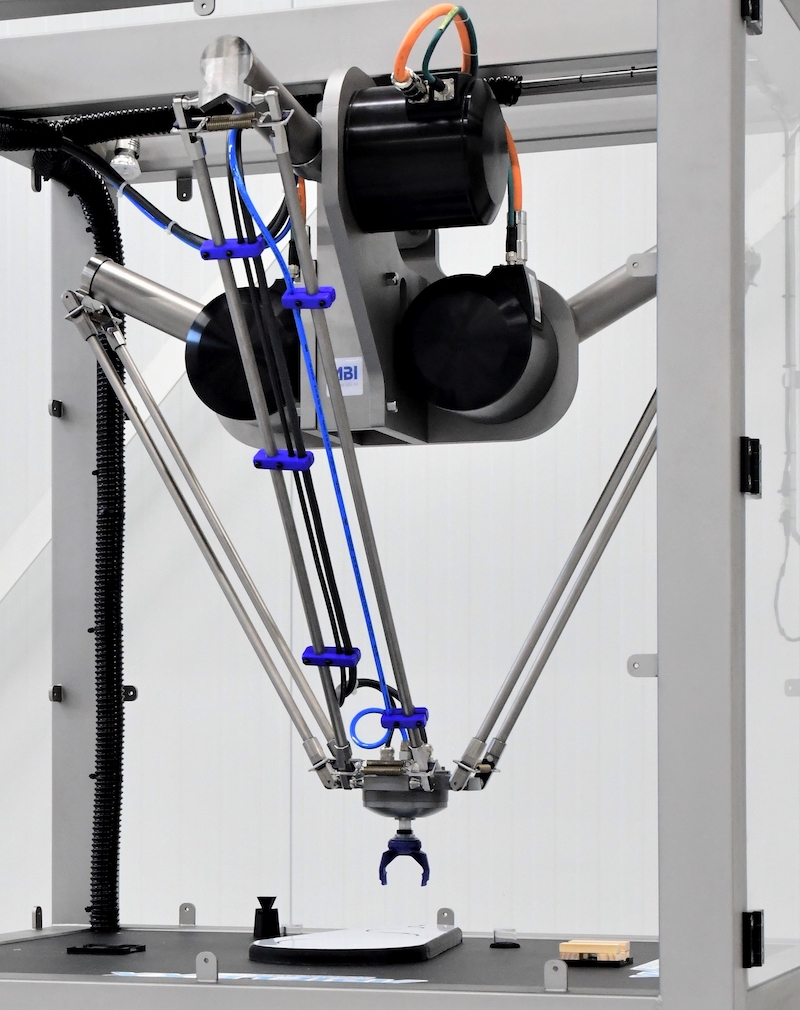

ABI launches new delta robot equipped with direct drives

September 7, 2023

VoIP Phone Systems: Automation in the World of Communication

January 7, 2023

Ritsumeikan University develops ‘soft microfingers’ for robots

November 14, 2022

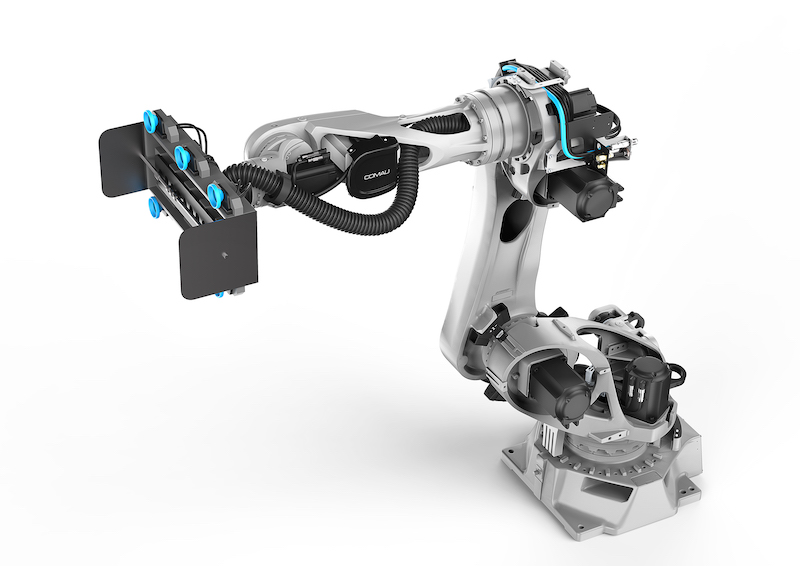

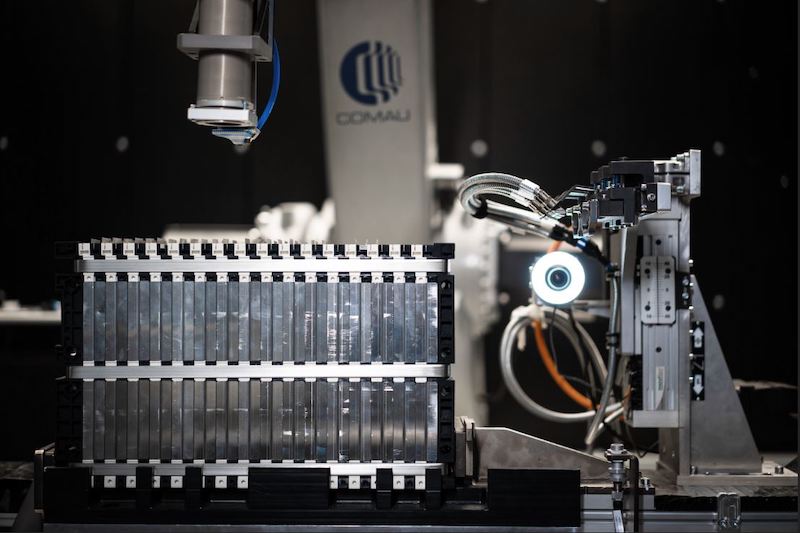

Comau launches new industrial robot

April 16, 2022