Comau launches new hemming process for vehicle manufacturing

Comau, a leader in advanced industrial automation, is taking a step forward in digital-enabled solutions for lightweight and electric vehicle manufacturing with its new robotic roller hemming process.

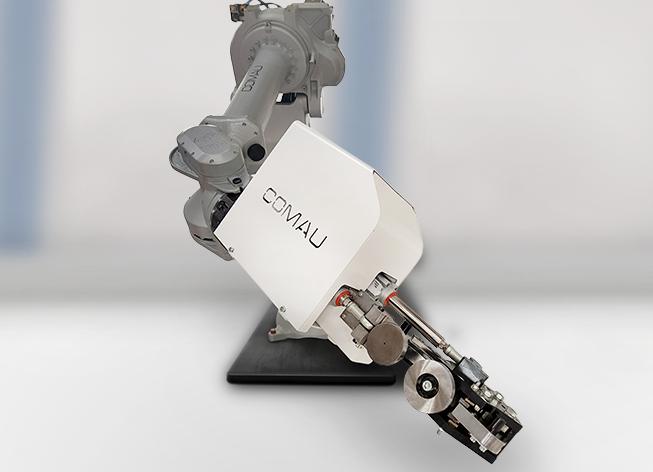

Smart Hemmer is a highly compact, symmetrical roller hemmer able to hem any complex joint.

It is hailed as a solution for the new generation of electric, hybrid and traditional lightweight vehicles as it is designed to allow automakers to join dissimilar materials using a cold process.

Its design features two flexible rollers in which the linear roller can automatically disengage when encountering obstacles or a curved path and avoids the the fixed anvil, apparent in all traditional roller hemming processes.

As a result, Smart Hemmer can perform curved path hemming and manage complex angles as part of a single, continuous process. It is also able to maintain a constant hemming thickness even when encountering multiple layers of dissimilar materials.

The result is an Industry 4.0-compliant hemming head, jointly developed by Comau and a world-class automotive manufacturer, which is said to offer high reliability, inherent flexibility and complete process control while ensuring the geometric uniformity of the assembled parts.

“Comau’s newest hemming solution features a revolutionary design that renders it extremely fast and efficient for lightweight and e-vehicle manufacturing, while eliminating the costly attributes of the product as well as the associated production process,” explains Giovanni Di Stefano, Head of Process Technologies.

“The Industry 4.0 compliant solution lets automakers innovatively join components together with full in-process monitoring of the joint.”

Field-tested and validated by major European automakers, Smart Hemmer is a standardised product that can be applied to all vehicle architectures.