Autistic adults face lower employment rates than their equally qualified peers, in part because many workplaces don’t meet their needs. Meanwhile, manufacturers are struggling to hire skilled workers, and they may be overlooking the autistic talent pool.

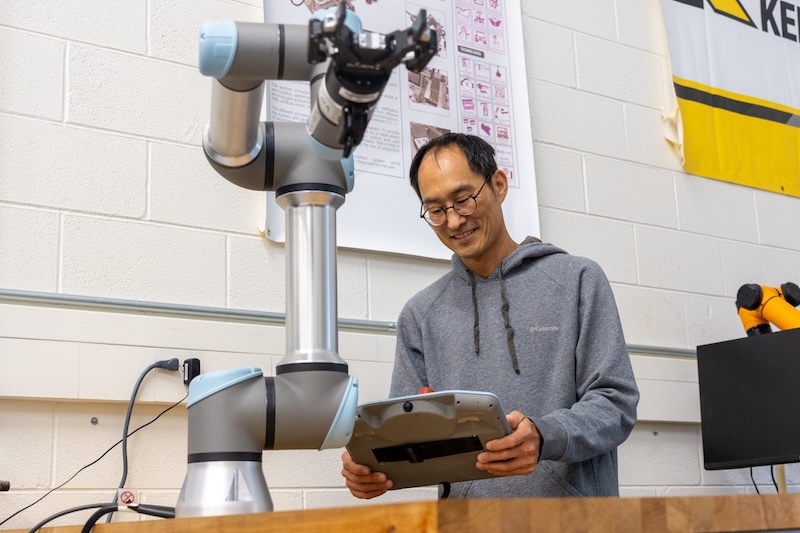

A team of researchers at Virginia Tech wants to solve both problems: increasing autistic employment rates and bolstering the manufacturing workforce by designing collaborative robots, or “cobots”, that can work alongside neurodivergent workers and provide real-time feedback and personalized support.

Funding the research is a National Science Foundation grant of over $1.5 million to collaborators at Virginia Tech, George Washington University, and the University of Notre Dame. Virginia Tech is leading the project, with its share of the grant totaling $800,000.

“One of the reasons we’re focused on autistic individuals is that they often face challenges finding employment, despite being as intelligent and capable as their peers,” said Sunwook Kim, research associate professor in the Grado Department of Industrial and Systems Engineering and the principal investigator for the project.

“We were noticing how difficult it was for undergraduates on the spectrum to get lab experience and the kind of work needed to secure internships, co-ops, and eventually jobs. With all the advances in AI (artificial intelligence) and smart technologies, now is a good time to focus on human-centered design in industrial environments.”

The multidisciplinary team of researchers includes:

- Myounghoon Jeon, professor, industrial and systems engineering, Virginia Tech

- Sol Lim, assistant professor, industrial and systems engineering, Virginia Tech

- Angela Scarpa, professor of psychology and director of the Virginia Tech Autism Clinic and Center for Autism Research

- Caroline Branscome, instructor in civil and environmental engineering and autism-centered design lead in the Virginia Tech Center for Autism Research

- Young Hoon Kwak, associate professor of data sciences, George Washington University

- Chung Hyuk Park, associate professor of biomedical engineering, George Washington University

- Zhi Zheng, assistant professor of electrical engineering, University of Notre Dame

“Each member of our team brings a different perspective – autism expertise, lived experience, human-centered design, AI, robotics,” Scarpa said. “Together, we’ll make sure the project is represented accurately.”

Where psychology meets engineering

The research is grounded in self-determination theory (SDT), a psychology framework that says people thrive when three basic needs are met: autonomy, competence, and relatedness.

The goal is to apply AI and smart technologies to the theory and design cobots that would be stationed near autistic or neurodiverse employees on a manufacturing floor.

Cobots, or collaborative robots, are designed to work safely alongside humans instead of behind a cage or in a box like traditional robots. Instead of replacing people, a cobot acts as a smart, careful teammate.

The cobots could, for example, provide responsive feedback, set work pace, and foster interaction that boosts a worker’s sense of autonomy, competence, and relatedness.

“Manufacturing is a pivotal domain right now because of advanced manufacturing – smart technologies are changing the landscape. Cobots are becoming more capable of interacting naturally with human workers,” Kim said. “Most studies focus on physical aspects like reducing physical strain, but we want to look at broader aspects like well-being.”

A new kind of workplace collaborator

The researchers soon will begin pilot studies, using sensors and simulated assembly tasks to understand how cobots can provide real-time support to autistic workers.

“We see cobots not as a replacement for human coworkers but as a bridge – a way to create the conditions for better interactions between autistic and neurotypical workers,” said College of Engineering Professor Myounghoon “Philart” Jeon.

“We’ll be collecting data to train the cobots, using AI algorithms to make them smarter. That’s really the core of the project.”

The team has also formed a steering committee that includes autistic individuals with manufacturing experience to ensure their perspectives directly shape the research. Instead of researchers deciding what autistic individuals in the field need, they wanted to bring those voices directly to the table.

“Traditional STEM research overlooks human-centered design approaches,” said Caroline Branscome, an autistic human-centered designer with the Center for Autism Research with experience in engineering and qualitative research. “So my role is to center our design on guidance from our steering committee.”

Her perspective highlights why the team’s human-centered approach matters: Technology alone can’t create change without listening to the people it’s designed for.

“We all vary in neurological processes, and it’s important to create environments that accommodate such differences,” said Scarpa.

“Autistic people have, in general, different ways of communicating and learning than neurotypical people. Our goal is to facilitate these positive environments between employers and employees, both autistic and neurotypical, to maximize success. Without everyone on board, even the best innovations won’t reach the people who need them.”