Forgis, a Zurich-based startup building the brain that makes plants autonomous, has announced a $4.5 million pre-seed funding round led by redalpine, with participation from Massimo Banzi, co-founder of Arduino, and other investors from deep tech and manufacturing.

“The West invented industry,” says Forgis in its press release, “and then forgot how to build. For decades, it outsourced factories, traded machines for spreadsheets, and watched production drift east. If Europe sparked the first industrial revolution, China is industrializing the second in the dark.”

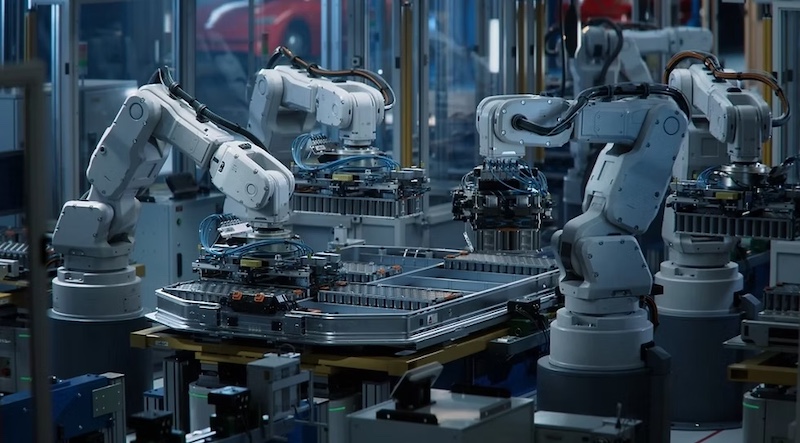

During the last decade, China’s industrial robot stock grew from 200 thousand to 2 million, 567 per 10 thousand workers surpassing Germany, the US, and the UK combined. Forgis wants to help the West close the industrialization gap, not through protectionism, but through intelligence.

Asian production lines now run without people. Robots assemble cars end-to-end, inspections are automated, and lights stay off because no one needs them on.

China has moved from the workshop of cheap labor to the command center of automation. BYD outsells Tesla, the EU lost the battery race, the West risks permanent industrial decline.

Three young founders decided not to watch the downfall, but to reverse it. Federico Martelli (26 years old), Camilla Mazzoleni (23), and Riccardo Maggioni (24) – from ETH Zurich and St. Gallen, ex- Google, Bain, and IBM – founded Forgis in 2025 to modernize industrial operations by making factories intelligent, collaborative, and flexible.

Its software runs “digital engineers” on the edge, AI agents that improve production performance in real time.

Federico Martelli, CEO of Forgis, says: “Minimizing downtime, maximizing throughput, and reducing quality scraps have always been critical challenges for manufacturers.

“But with systems built 40 years ago, factories keep losing millions. We’re bringing state-of-the-art physical AI to the factory floor, where it actually matters”.

From forge plus genesis, Forgis will bring the next industrial revolution, turning factory automation into a plug-and-play ecosystem, as Microsoft once did for personal computing.

Camilla Mazzoleni, CPO of Forgis, says: “It’s a revolution built from the inside out. We’re not replacing legacy systems or industry standards. We plug into what’s already there and upgrade every inefficient step with advanced intelligence.”

In early pilots with European manufacturers, Forgis has reported configuration times reduced by up to 60 percent, downtime by 30 percent, and throughput increases of around 20 percent.

Riccardo Maggioni, CTO of Forgis, says: “We’re bringing production back to the West by adding an intelligent software layer to existing factory ecosystems. This way, reshoring becomes the smarter, not the costlier, choice.”

redalpine’s investment reflects a broader shift in European venture capital – a growing belief that deep tech doesn’t have to move slowly. “We closed in 36 hours because the conviction was mutual,” says Gianmarco Hodel, investment manager at redalpine. “This is what Europe needs more of: speed, belief, and boldness.”

Collaborations and next steps

Forgis is already working with IBM and has projects underway in the automotive and advanced manufacturing sectors.

The company’s platform integrates with existing systems from vendors such as Siemens and ABB, making complex industrial environments more flexible and efficient.