Robotics is reshaping electronics manufacturing like a quiet electric tide, lifting factories on every continent into a new era of precision and scale.

As devices grow smaller, production cycles grow faster, and global demand grows louder, automated systems are stepping in to handle tasks that once pushed human limits.

From foundational control layers to advanced collaborative robots, automation is becoming the backbone of how smartphones, circuit boards, and high-tech components are built.

Around the world, companies are weaving robots into their production lines to cut errors, boost throughput, and future-proof operations, signalling the rise of a truly global robotic manufacturing ecosystem.

Robotics in the Electronics Supply Chain – a Ground-Level Revolution

In the realm of electronics manufacturing, the integration of robotics has shifted from novelty to necessity – and doing so demands attention even at the basic “asp level 1” of system implementation.

At the heart of many smart factories lies the term asp level 1 – the foundational architecture of automation, system programming and real-time monitoring that connects robots, conveyors, and inspection machines in a high-volume electronics line.

While that may remind one of an electrical contractor’s certificate, linking to how work is structured at basic levels of qualification (for example through sites such as the Integrum Power Group, providing level-1 electrician services in Newcastle), the analogy is apt: just as a building relies on certified foundation-work, a smart manufacturing line depends on well-architected level-1 automation.

The reason robotics are moving to the core of electronics manufacturing is clear: as manufacturers of smartphones, PCBs, modules and final consumer devices face ever tighter margins, ever smaller components and ever shorter product-life cycles, the only way to sustain scale is via machines that deliver speed, precision, repeatability and minimal scrap.

Indeed, as reported, the annual installations of industrial automation in the electronics & electrical industry grew by 24% between 2019 and 2021.

Robots in electronics are now used for tasks from pick-and-place of tiny components, PCB handling, automated glue and inspection applications, up to full module assembly under “clean room” or ESD-safe environments.

They allow manufacturers to respond to product variants, speed-up changeovers, reduce labour risk and improve yield.

The “asp level 1” concept underlines that even at the microbial level of the automation stack – sensors, PLCs, motion programming – success or failure hinges on proper planning, wiring, calibration and software integration.

ABB Robotics – a Global Leader in Electronics Automation

A prominent example of robotics scaling in electronics manufacturing is ABB Robotics. The company offers an integrated portfolio of industrial and collaborative robots, autonomous mobile robots (AMRs), controllers and application solutions targeted at industries including electronics.

In electronics, where speed, cleanliness (dust-free, ESD-safe), and precision are paramount, ABB’s technologies are used by manufacturers to handle everything from semiconductor wafer handling, module stacking, to consumer device assembly lines.

As the electronics sector continues to leap into smart-factory territory, ABB’s emphasis on modularity, flexible cells, and advanced software is central.

According to a recent story, ABB even plans to spin off its robotics business as a separate entity by Q2 2026 — underscoring how strategic robotics is becoming in manufacturing.

For global electronics manufacturing, ABB’s significance lies in its scale, its ecosystem of partners, and its software-hub orientation.

Electronics makers can deploy robotic cells that adapt across product lines — a key step given the high-mix, low-volume challenges typical in consumer electronics.

The bottom line: when a manufacturer deploys ABB robots, the automation stack moves beyond “asp level 1” wiring to full ecosystem-level orchestration.

NEXTY Electronics – Japan’s Smart-Factory Integrator for Electronics

On the other side of the globe, Japan’s NEXTY Electronics is making waves in smart-factory deployment for electronics manufacturing, with robotics deeply embedded in its strategy.

The company – part of the Toyota Tsucho group – provides solutions for digitalising factories, robotics integration, logistics automation and variable-mix/variable-volume production.

According to its own communications, NEXTY opened a showroom in Nagoya in 2023 that demonstrates a 3-robot cell where three industrial robots (from different manufacturers) work together via automatic motion-planning rather than manual programming – reducing set-up time and enabling rapid changeover.

In the context of electronics manufacturing, NEXTY’s role is to bridge the gap between component makers (PCBs, modules, wiring harnesses) and the demands of modern assembly: clean-rooms, high automation, logistics-feeds, and quality systems.

For example, they help factories face labour-shortage issues by deploying robot/AGV systems, digital dashboards and real-time monitoring.

This shows how robotics is not just machinery, but system-integration: the “asp level 1” wiring matters, but so does the higher layers – motion planning, vision, real-time data. NEXTY helps electronics factories deliver that stack.

Robotphoenix – Precision Robotics for 3C / Electronics Manufacturing

Finally, from China emerges Robotphoenix, a specialist in robotics targeted at “3C” electronics (computers, communications, consumer devices) where component sizes shrink, volumes soar, and automation must meet ultra-tight precision.

Their robots are used for tasks such as component patching, assembly of small parts, TWS-earphone cord placement and more, with accuracy up to ±0.035 mm and throughput over 7,200 units per hour.

They emphasise clean-version robots (dust-free, static-free) tailored for electronics manufacturing lines. For manufacturers of smartphones, modules, and PCBs, Robotphoenix offers high-speed pick-and-place, packaging, unloading and loading functions. Their clean-robot version meets the environmental demands of electronics lines.

This company highlights how robotics has moved into ever finer domains: precision handling of micro-components, ultra-fast logistics, self-organising fleets of mobile robots in electronics factories.

The trend shows that global electronics manufacturing is no longer generic mass-assembly – it’s high-precision, high-mix, highly automated – and robotics companies like Robotphoenix are tailor-making solutions for that.

Endnote

Robotics has stepped out of the research lab and into the heart of global electronics manufacturing. From establishing robust “asp level 1” automation foundations (analogous to electrical contractor standards) to deploying advanced robotic orchestration systems, the wave is now unstoppable.

ABB Robotics shows how large-scale automation platforms enable electronics factories to scale globally; NEXTY Electronics demonstrates how smart factories integrate digital, motion-planning, and robot-cells for modern production; and Robotphoenix highlights how precision robotics serve the niches of 3C electronics at break-neck speed and fidelity.

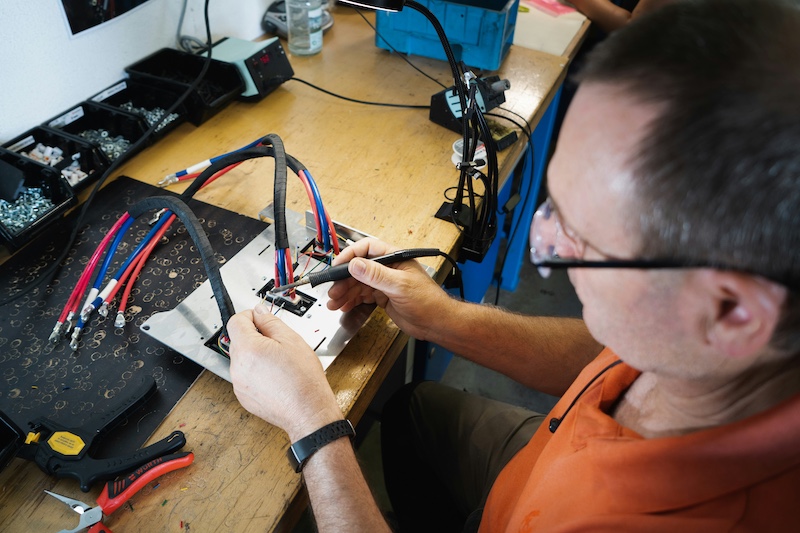

Main image by Sufyan on Unsplash