AutoStore and Kardex have completed the installation of a fully operational automated storage and retrieval system (ASRS) for Balluff in just six months, a timeline the companies describe as a record.

Balluff, a global sensor and automation specialist headquartered in Germany, needed a solution to modernize its intralogistics operations. The company selected AutoStore’s cube storage technology, integrated and delivered by Kardex, to improve efficiency and meet growing demand.

According to the partners, the project was completed from contract signing to go-live in only half a year, significantly faster than typical deployment timelines for large-scale warehouse automation.

AutoStore spokesperson says: “This project sets a new benchmark for how quickly high-performance logistics systems can be deployed. Working closely with Kardex and Balluff, we were able to compress timelines without compromising quality or reliability.”

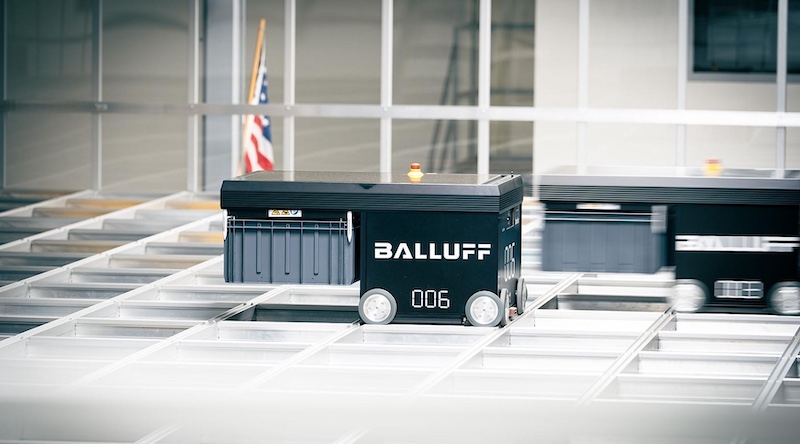

The system uses AutoStore’s robotic storage and retrieval technology, which maximizes space utilization by stacking bins vertically in a compact grid. Kardex handled project integration, including system design, implementation, and training.

Balluff says the new system will help it streamline warehouse operations and ensure higher productivity.

Balluff representative says: “With AutoStore and Kardex, we have implemented a future-proof intralogistics system in record time. The solution allows us to better serve our customers while improving efficiency and scalability.”

Kardex highlighted its ability to accelerate project delivery without disrupting Balluff’s existing operations.

Kardex spokesperson says: “The success of this project demonstrates the value of close collaboration between technology providers and customers. We are proud to have delivered a fully operational system in just six months.”

AutoStore and Kardex plan to build on the project as demand grows for rapid-deployment warehouse automation in Europe and beyond.