By Ulrich Schäfer, project engineer, Zasche Handling

Manufacturers today are navigating an increasingly complex balancing act. High-mix production, persistent labour shortages, and stricter safety and ergonomic standards are stretching both operators and processes.

Manual handling can no longer keep pace without risking fatigue or injury, yet fully robotic systems are often rigid, costly, and hard to adapt to changing part types. Between these extremes lies a growing opportunity for solutions that blend human expertise with targeted automation.

Semi-automated bin picking sits squarely in this middle ground. It offers a practical alternative when full automation would require disproportionate investment, yet manual lifting and handling exceed what is safe or sustainable over time.

Rather than eliminating human involvement, this approach preserves operator judgment where it matters most, while shifting the physical burden of handling to systems designed for consistency and endurance.

Reframing bin picking: Shared work, shared strength

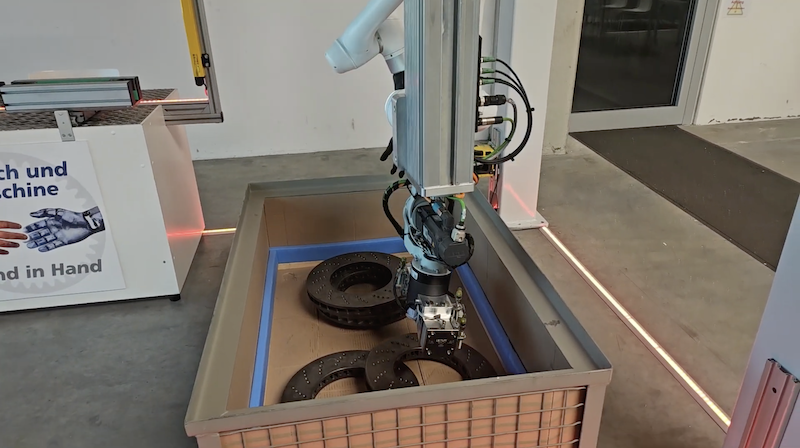

Components can be picked directly from disordered containers, with the system identifying each part’s position and adjusting the gripper accordingly.Discussions around bin picking have long been dominated by robotics. In many real-world applications, however, the goal is not to replace the operator but to support them.

Semi-automated bin picking reframes the task as a collaborative process, a dynamic that is easier to appreciate when seen in operation (a short demonstration video illustrates this interaction).

Force-intensive movements are handled mechanically, while operators remain responsible for work that demands dexterity, timing, and situational awareness. The result is a division of labour shaped by the respective strengths of humans and machines.

This hybrid model addresses the limitations on both ends of the automation spectrum. It alleviates the physical strain inherent in manual work, while avoiding the rigidity of fully automated cells that often require extensive reprogramming when parts or processes change.

Because these systems are easier to adjust and redeploy, they are not confined to large-scale operations alone. Smaller manufacturers can also adopt semi-automation as a way to improve safety and productivity without committing to disruptive infrastructure overhauls.

Crucially, this flexibility also extends to how parts are presented. Components do not need to be precisely arranged in advance, and in many cases, complex or purpose-built containers can be avoided altogether – reducing upstream handling effort and unnecessary cost.

Why human-centric automation delivers more

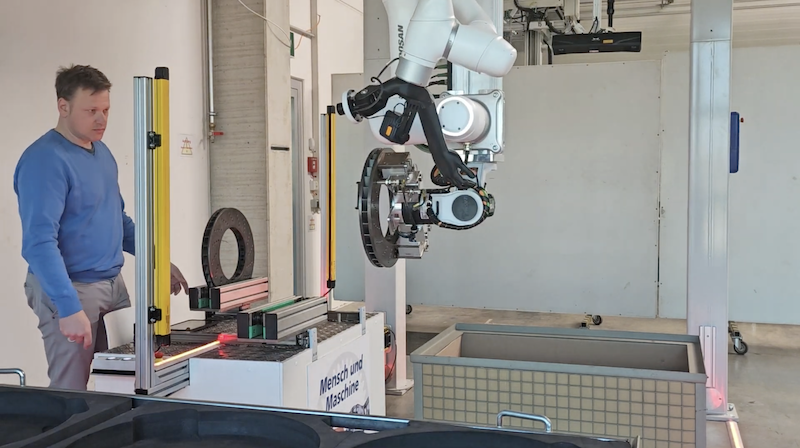

Parallel workflows in action: manual processing at the operator station while the system retrieves the next component behind a defined safety boundary.

What distinguishes semi-automated handling from conventional robotic setups is its emphasis on keeping operators actively engaged in the process.

Human expertise remains central, while automation provides the strength, stability, and repeatability needed to manage demanding handling tasks. This balance creates a workflow in which people guide the process and technology reinforces it.

On the factory floor, this collaboration translates into tangible benefits. By relieving operators of the most physically taxing motions, they are free to concentrate on precision, coordination, and real-time decision-making.

Accuracy improves, fatigue is reduced, and work becomes more sustainable over long shifts – without sacrificing control or responsiveness.

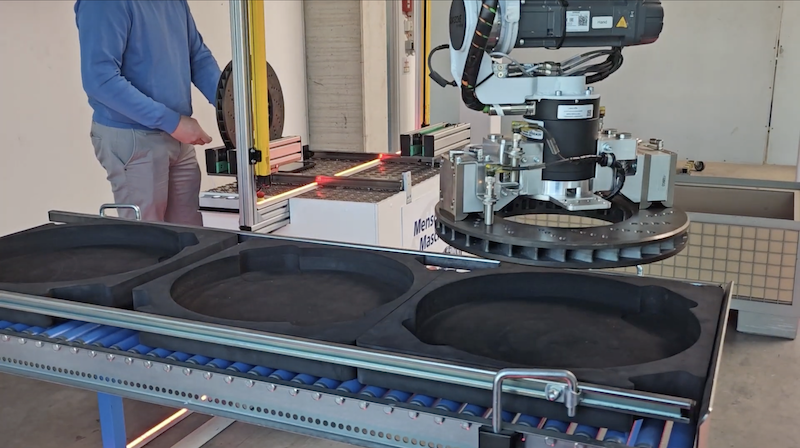

At the same time, these systems allow power and finesse to coexist. Semi-automated platforms deliver lifting capability and motion control that manual handling cannot achieve reliably, while still leaving final positioning and adjustment in human hands.

This combination enhances both safety and consistency, particularly in applications where delicate placement matters as much as load capacity.

Once the operator has completed the manual task (for example, inspection, assembly preparation), semi-automatic solutions can support controlled placement into the next stage of the process.

Adaptability further strengthens the case. Flexible grippers, modular end-effectors, and intuitive control interfaces allow teams to accommodate new parts, layouts, or batch sizes with minimal disruption.

Operators can interact with semi-automated setups through sensors, simple push-button controls, or tablet-based adjustments depending on task complexity.

In environments where components arrive in mixed or disordered containers, integrated sensing and orientation support help maintain efficiency – without forcing the surrounding process to conform to the automation.

Taken together, these attributes – collaboration, capability, and adaptability – demonstrate why human-centric systems remain a pragmatic path forward.

They elevate the work people do best while assigning physically demanding or repetitive tasks to machines, resulting in operations that are safer, more flexible, and better aligned with real-world production conditions.

Practical progress, not grand overhauls

Across industry, there is a growing recognition that “smarter” does not always mean “fully automated”. Many of today’s most effective improvements come not from replacing processes entirely, but from strengthening them in targeted, meaningful ways.

Semi-automated bin picking exemplifies this mindset: improving safety, raising efficiency, and preserving flexibility without imposing rigid workflows.

More importantly, it reinforces a perspective that often gets lost in the automation narrative. Progress does not need to be disruptive to be transformative.

When systems are designed to complement human capability rather than constrain it, the combination of machine strength and human judgment becomes a strategic advantage – one that manufacturers of all sizes can apply.

As industrial environments continue to evolve, the question is no longer whether automation should replace people. The more compelling question is how technology can extend what people do best while freeing them from tasks that machines are better suited to handle.

Semi-automated bin picking offers a compelling answer – and a glimpse of how human skill and intelligent assistance can operate not in competition, but in concert.