Spike Dynamics is a young robotics company with an unusually ambitious goal: to make machines move like living tissue.

Based in the United States and led by founder and CEO Alexander “Sasha” Sergeev, the company is developing ultra-compact, muscle-like piezoelectric actuators that can deliver high precision and force at microscopic scales.

Originally designed for intravascular medical robotics – devices small enough to navigate inside the human body – the technology is now finding potential applications far beyond medicine, from humanoid robots to space exploration.

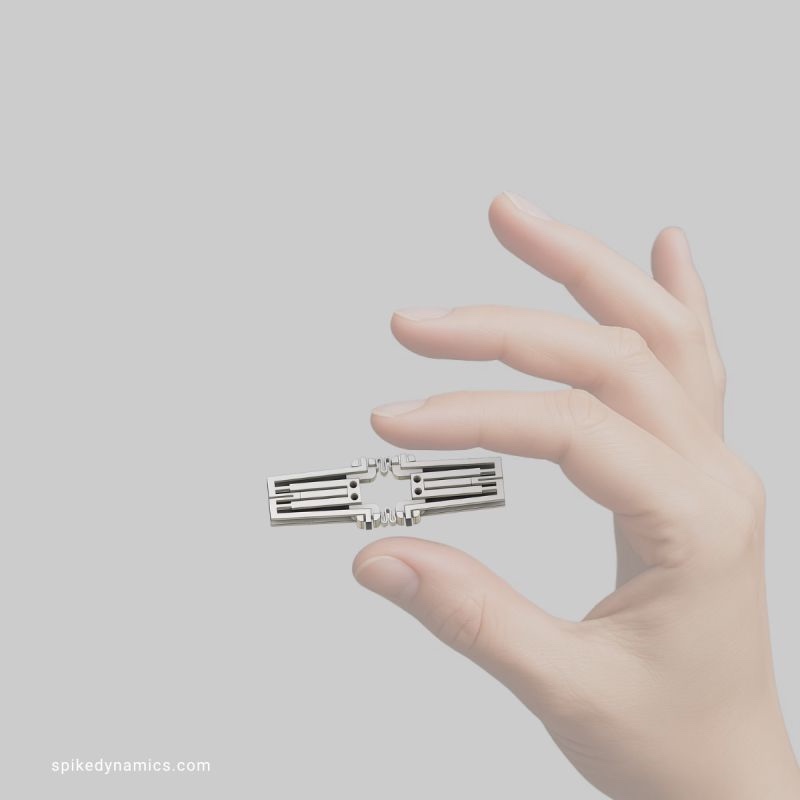

At the heart of Spike Dynamics’ work is the SP1, a 5-millimetre, non-magnetic microrobotic platform for cardiovascular diagnostics and therapy.

To reach that goal, the team engineered a new class of linear piezo actuators and drive electronics capable of producing smooth, gearless motion without magnetic interference – a breakthrough for environments where electromagnetic systems are unsuitable.

Recognising the broader value of their actuator technology, Sergeev and his team have taken the unusual step of open-sourcing a non-medical subset of their platform.

By releasing reference designs, firmware, and performance data, they aim to accelerate innovation and build a community of roboticists, engineers, and researchers around their core technology.

In this interview with Robotics & Automation News, Sergeev discusses why Spike Dynamics decided to make part of its technology open source, the advantages of piezo-based actuators over traditional motors, and how the company’s dual-path strategy – balancing regulated medical development with open collaboration – could reshape the future of microrobotics and precision motion systems.

Interview with Sasha Sergeev, CEO of Spike Dynamics.

Robotics & Automation News: Open-source strategy – What motivated Spike Dynamics to make your micro linear piezo actuator technology open source, and what kind of community or ecosystem do you hope to build around it?

Sasha Sergeev: Why we opened (part of) the tech: Our flagship program is a 5 mm, non-magnetic, muscle-like microrobotic platform for intravascular diagnostics and targeted therapy.

To get there, we developed ultra-compact linear piezo actuators and drive electronics that are unusually small yet high-force/precise.

During prototyping we realized two things

- this actuator stack has far broader utility than our initial cardiovascular use case; and

- the fastest way to validate, harden and extend it is to let the best engineers in the world use it, break it, and improve it in public.

So we split the technology: the medical device stack (SP1) remains proprietary and regulated; a non-medical subset of our micro linear piezo actuator technology is released as open source.

This lets us focus the core team on SP1 while creating a powerful external “R&D multiplier” around everything that does not require clinical controls.

What exactly we open and what we keep closed

- Open (non-medical subset): reference actuator designs, controller firmware, interface specs, CAD for test fixtures, BOMs, tuning methods, performance datasets, and example applications (robotic joints, grippers, end-effectors).

- Closed (medical/regulated stack): device-level architectures, clinical control logic, manufacturing tolerances and processes, biocompatible material selections, reliability and risk models, and SP1 system integration.

This separation preserves our competitive moat and regulatory compliance while still giving the community something truly useful.

Motivation in one line: open sourcing the non-medical layer accelerates adoption and learning, while the SP1 medical program stays protected and focused.

The ecosystem we’re building

- Audience: robotics teams (humanoids and dexterous manipulation), prosthetics labs, precision automation, aerospace/space robotics, and high-end hobbyists/academia.

Why this helps Spike’s business

- Open work is a magnet for top engineers; many of our future hires and advisors will come from contributors already fluent in our stack.

- Companies evaluating us can prototype with the open actuators first, then graduate to commercial agreements when they need higher performance variants.

- Downloads, forks, and design-ins create measurable traction that strengthens our fundraising and strategic dialogues.

- While SP1 moves through pre-clinical and regulatory gates, the open ecosystem creates parallel opportunities (hardware kits, reference modules, services, and co-development).

The community we want to see 12-24 months from now

A self-sustaining network where teams publish actuator-powered hands, wrists, micro-positioners and soft-robotic modules, where our repos are the default reference for compact, high-force linear motion; and

where a fraction of those users convert into partners, customers, hires, and SP1 collaborators.

R&AN: Technical edge – In practical terms, what advantages do your actuators offer over traditional motors or actuators when it comes to replicating muscle-like movement in robotics?

SS: At the heart of our technology is a new class of ultra-compact linear piezo actuators that deliver muscle-like performance – combining high precision, high force, and high durability in a form factor small enough to fit inside a pen tip.

Traditional electromagnetic motors rely on rotation and mechanical conversion, which limits how small and efficient they can become. Our actuators, in contrast, produce direct linear motion, meaning no gears, no lubrication, and no magnetic interference.

They can function in extreme environments – from inside the human body to outer space – and maintain full force output even at micro-scale.

In practical terms, this allows engineers to design machines that move more like living tissue – soft, compliant, and adaptive – rather than rigid assemblies of parts. This is why we often describe them as “dry artificial muscles”.

By eliminating friction, backlash, and wear, our actuators achieve millisecond response times and unprecedented power density for their size.

This makes them ideal for next-generation robotics, precision instruments, and any application that requires compact, reliable, and controllable linear motion.

R&AN: Use cases and industries – Beyond academic research, where do you see the most immediate applications for this technology – for example in humanoids, prosthetics, or precision medical devices?

SS: While our core focus is medical – specifically cardiovascular micro-robotics – the underlying actuator technology has far broader potential. Its combination of compactness, strength, and precision opens opportunities across multiple industries.

The most immediate applications are in humanoid robotics, prosthetics, and precision medical devices – areas where muscle-like motion, size, and control matter most. In humanoids, our actuators can enable lifelike dexterity without bulky servos.

In prosthetics, they can deliver smoother, quieter, and more natural limb movement. And in surgical and diagnostic devices, they enable motion at a millimeter scale with zero magnetic interference – critical for working near sensitive imaging equipment or within the human body.

Beyond healthcare, we see applications in aerospace, defense, and industrial automation, where durability and reliability under extreme conditions are key.

Because our actuators are non-magnetic, dust-proof, and radiation-resistant, they can operate in environments that defeat traditional motors – from vacuum chambers to outer space.

This cross-industry adaptability is what makes the technology so powerful: the same principles that allow a robot to operate safely inside the heart can also drive precision systems in manufacturing, exploration, or defense.

R&AN: Commercial model – With the core technology being open source, how does Spike Dynamics plan to sustain and grow commercially – through hardware sales, licensing, services, or partnerships? And looking ahead, what new developments or milestones should we expect from Spike Dynamics over the next 12-18 months?

SS: Spike Dynamics operates on a dual-path model – combining a focused medical device strategy with an open-source technology ecosystem.

Our closed, regulated pathway is centered around SP1, our 5 mm intravascular robotic device designed for cardiovascular diagnostics and interventions.

In parallel, the open-source actuator platform allows us to engage a global engineering community, accelerating innovation and creating early partnerships across industries.

Commercially, this approach gives us a strategic advantage: while the FDA process for SP1 progresses, we continue to generate momentum, visibility, and collaboration opportunities through our open hardware line.

This not only strengthens our brand but also builds relationships with potential partners and acquirers in robotics, aerospace, and medtech.

Our revenue model includes hardware licensing, joint development agreements, and strategic partnerships, alongside long-term commercialization of SP1 in the cardiovascular domain.

Over the next 12-18 months, Spike Dynamics will complete in-vitro validation and preclinical design studies, secure new institutional collaborations, and raise Series A funding to initiate GLP animal studies and the IDE submission to FDA.

Beyond that, our Series B phase will include pivotal trials, regulatory submissions, and global commercialization, followed by the rollout of AI-powered robotic control systems and scalable actuator manufacturing for broader adoption.

Through this dual-track model, we are not just developing a medical device – we’re establishing the foundation for an entire class of intelligent, minimally invasive robotic systems.