Kollmorgen has announced a collaboration with sensor specialist ifm to tackle one of the persistent challenges in warehouses: misaligned pallets disrupting automated workflows.

In many logistics and production sites, manually placed pallets can be slightly off-coordinate, causing problems for automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) that depend on precise positioning.

These errors can result in failed docking attempts, delays, and reduced productivity.

To address this issue, Kollmorgen introduced NDC Flex in 2023, a solution designed to bridge the gap between manual labour and automation. One of its core functions, Dynamic Load Docking, enables vehicles to detect and align with the actual position of pallet loads in real time.

Integration of ifm 3D cameras

Following an evaluation of different approaches, Kollmorgen selected ifm’s 3D camera technology as the optimal fit for its system. The two companies have since worked together to integrate the cameras into the Dynamic Load Docking capability.

Kollmorgen added support for camera integration in its software, allowing vehicles to handle off-coordinate pallet placements with greater accuracy. According to the companies, this ensures smoother and more reliable handovers between human workers and automated systems.

Technical collaboration

The partnership involved joint technical meetings, equipment testing, and close cooperation between engineering teams. ifm provided access to its hardware, while its application engineer worked alongside Kollmorgen to complete the integration.

The result is a system where the camera communicates directly with the vehicle through its video-process unit, enabling dynamic route adjustments based on real-time data.

Benefits for operations

Kollmorgen says the addition of ifm’s technology allows businesses to deploy smarter docking systems without sacrificing throughput or efficiency. The functionality is available immediately through Kollmorgen’s partner network.

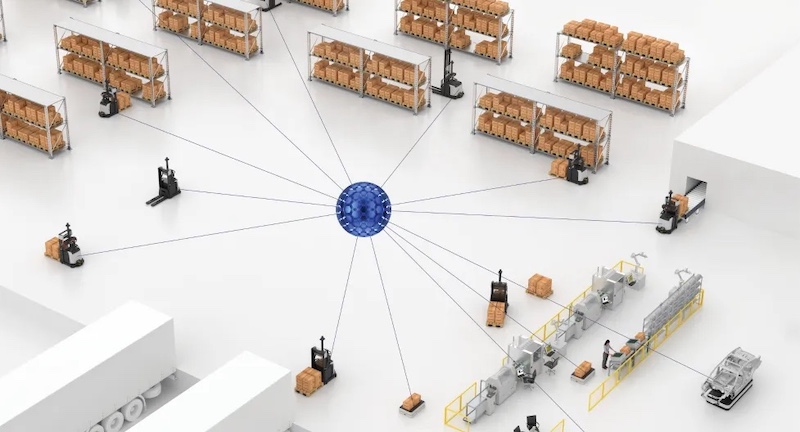

NDC Solutions by Kollmorgen is already widely used by vehicle builders to develop driverless logistics systems across industries. By integrating ifm’s vision technology, the company aims to further strengthen automation reliability in warehouse and production environments.