How to do laser engraving on metal?

Laser engraving is a technology that uses a focused beam of light to permanently mark a material’s surface. It can engrave a variety of materials, including metals.

In metal engraving, the laser beam vaporizes the metal at the point of contact, creating a clean and precise design or inscription. This article describes how laser engravers can engrave metal materials and machines that are capable of metal engraving.

Laser Engraving for Metal: Precision and Permanence

Laser engraving utilizes a focused beam of light to permanently mark a metal surface. This technology offers a unique set of advantages that make it ideal for various metalworking applications.

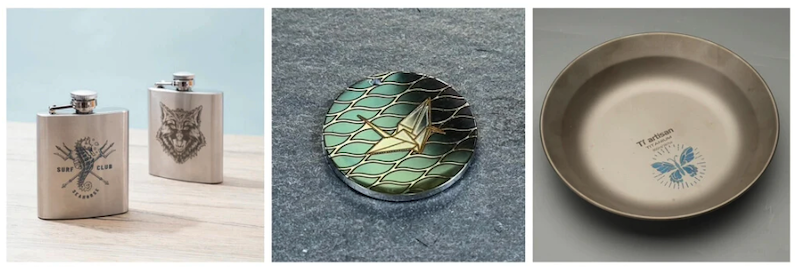

Metal handicrafts

These advantages make laser engraving machines a valuable tool for various industries. Individuals can also apply engraving techniques to personalize metalwork.

- Decorative items: Serializing parts, marking logos, and creating custom labels.

- Jewelry and Accessories: Personalizing jewelry, engraving trophies, and creating custom keychains.

- Signage and Nameplates: Creating durable and professional signage.

- Decorations: murals, screens, lamps, mirror frames, and so on.

Advantages of laser engraving for metal

- Durability: Laser engravings create a deep impression on the metal surface, resulting in markings that are highly resistant to wear and tear. This makes them perfect for applications like serial numbers on tools, identification tags on equipment, or personalized engravings on jewelry.

- Precision: Unlike traditional engraving methods, lasers can create incredibly intricate and detailed designs. This allows for high-quality logos, complex artwork, or even data matrix codes to be permanently etched onto metal with exceptional accuracy.

- Versatility: Laser engravers can work on a wide variety of metals, from aluminum and stainless steel to brass and titanium. By adjusting the laser’s power settings, you can achieve different engraving depths, from light etching to deep grooves.

- Cleanliness: The laser engraving process is contactless, minimizing the risk of surface damage or contamination to the metal compared to traditional methods like mechanical engraving.

- Repeatability: Laser engraving ensures consistent and accurate results every time. This is crucial for applications requiring identical markings on multiple metal pieces.

- Speed and Efficiency: Compared to manual engraving, the laser process is significantly faster, especially for repetitive tasks. This translates to increased productivity and faster turnaround times.

Overall, laser engraving offers a precise, permanent, and versatile solution for marking metal. Its clean, efficient, and repeatable nature makes it a valuable technology for various applications across different industries.

Method of laser engraving metal

Preparing the following tools

- Suitable Metal Sheet: All types of coated and uncoated metals, including stainless steel, copper, brass and aluminum, are suitable for laser engraving.

- Choose a supportive laser engraver for metal: There are different types of desktop laser engravers. Of these, fiber and infrared lasers can engrave all types of metal. However, for DIY projects and small businesses, you may prefer an infrared laser engraver. You can consider the portable engravers xTool F1 and the powerful xTool S1 as your productive tools.

- Design and Software: Create your design using compatible software and ensure it’s formatted for your laser engraver.

Engraving Process

- Laser Settings: Consult your laser’s manual or manufacturer’s recommendations for optimal settings based on the metal type, thickness, and your desired engraving depth. It’s advisable to experiment with test pieces to find the ideal settings for your project.

- Software Settings: Enter the thickness or diameter of the metal in the software. This helps the machine to adjust the laser head for proper engraving depth. Some machines also have a manual knob for height adjustment.

- Engraving: Secure the metal piece firmly in the designated area of the laser engraver. Initiate the engraving job according to your design and software instructions.

For deeper engravings, multiple passes might be necessary, but usually, a couple of passes suffice for simple designs.

Additional Tips

- Start Simple: For beginners, choose a basic design for your first engraving attempt.

- Ventilation: Consider using proper ventilation to remove fumes produced during the engraving process.

- Safety Above All: Always prioritize safety and follow the manufacturer’s safety instructions for your specific laser engraver.

Additional points to consider

- The engraving process speed depends on the design complexity, metal type, and desired depth.

- Some laser engravers offer software features for previewing the engraving outcome before starting the actual process.

- More advanced techniques like image dithering can be used for creating grayscale or photographic images on metal surfaces.

Remember, consulting your laser engraver’s manual and experimenting with scrap materials are crucial for achieving the best results in your metal engraving projects.

Ideas of Metal Prints

Some creative engraving ideas that can help you to develop limited ideas about metal engraving and dig deeper into the art of metal engraving.

Using Photos

- Nature Scenes: Breathtaking landscapes, mountains, waterfalls, or wildlife photos take on a whole new level of vibrancy and detail on metal.

- Cityscapes: The metallic finish complements the modern feel of urban photography, highlighting city lights, skylines, or architectural details.

- Travel Memories: Commemorate special trips with metal prints of your favorite travel photos, capturing the essence of a place you visited.

- Family Photos: Showcase cherished family moments with a touch of modern elegance using metal prints.

- Black and White Photos: The high contrast and depth of black and white photos are especially well-suited for the reflective surface of metal prints.

Creative Applications

- Photo Collages: Combine multiple photos on a single metal print to create a unique and personalized artwork.

Signage: Create a durable and stylish sign for your home business, office, or even a special event using a metal print. - Wall Art Installation: Arrange multiple metal prints of varying sizes and designs to create a dynamic and captivating wall display.

- Tabletop Decor: Use smaller metal prints as coasters or decorative accents on a table or shelf.

Personalized Gifts: Metal prints with a special message, photo, or artwork make a unique and lasting gift.

Conclusion

In contrast to before, metal engraving is no longer a difficult task, all you need is a laser engraving machine and you can complete your ideas at home. Metal engraving is fun and completing the work gives a sense of achievement, you can start making your first metal piece now!