Gecko-inspired adhesive offers a bio-inspired twist on robotic handling

Researchers develop a technique to allow fragile objects to be transferred and released by robotics, without damage, while using a gecko inspired adhesive.

The subtle adhesive forces that allow geckos to seemingly defy gravity, cling to walls and walk across ceilings have inspired a team of researchers in South Korea to build a robotic device that can pick up and release delicate materials without damage.

The team, based at Kyungpook National University and Dong-A University, has published their research work in Science and Technology of Advanced Materials, an international science journal.

The researchers are hoping it can be applied to the transfer of objects by robotic systems.

The dry but sticky secret of a gecko’s foot lies in its coating of tiny hairs- made of protein- called micro setae.

These hairs are around 100 micrometers long and 5 micrometers in diameter. Each hair divides into a number of branches that end in flat triangular pads called spatulae.

The spatulae are so small that their molecules interact with those of the surface the gecko is climbing. This creates weak forces of attraction between these molecules, known as van der Waals force. This force is strong enough to hold the gecko in place.

The gecko’s innate adhesive ability has drawn the attention of many researchers and has inspired the use of its adhesion mechanism in robotics.

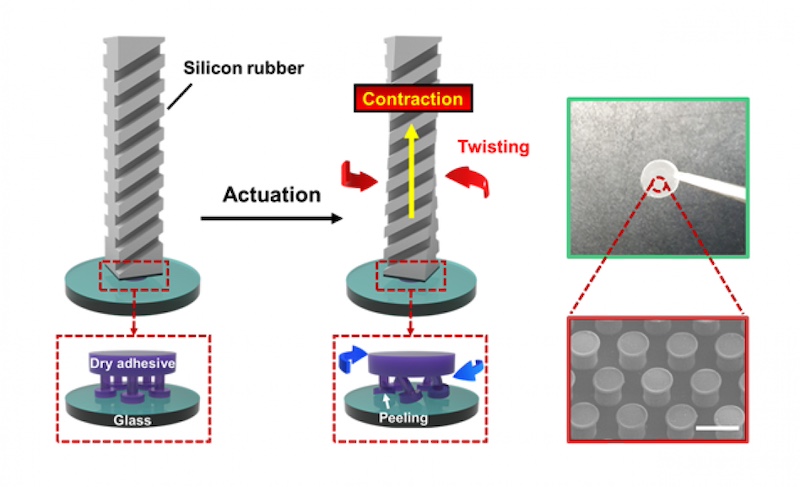

An artificial, mushroom-shaped dry adhesive, that mimics this mechanism, has been used to robotically pick up materials.

However, the force needed to detach the adhesive from the material’s surface can lead to its damage, especially if the material is fragile, such as glass.

Seung Hoon Yoo, first author of the research article, says: “There have been problems in getting the adhesive to detach easily.

“In order to exploit these adhesive powers in robotic systems, it is imperative that the robot can not only pick up an object, but also readily detach from it to leave the object in its desired location.”

In their study, the team resolved this detachment problem by using a vacuum-powered device, made of soft silicon rubber.

In order to detach the dry adhesive without damaging the fragile object being moved, a new detachment method was introduced.

This method involves a twisting and lifting motion that pulls the dry adhesive off of the glass surface without causing any damage to it.

The researchers found that the addition of this twisting motion caused a ten-fold reduction in the force required for detachment, which could be vital when handling delicate materials.

On conducting tests in which their transfer system was attached to a robotic arm, the researchers demonstrated that it could pick up a delicate glass disc from a sloping surface, move it to a different location and gently set it down without causing any damage to it.

Sung Ho Lee, one of the study’s authors, says: “We expect our research will garner significant interest from the industry, since many companies are very interested in using dry adhesives for temporary attachment and movement of components, especially in robotic applications.”

He added that his team hopes to serve as a bridge between research and industry by applying it to real industrial applications and developing more advanced models.