Single vs Heavy Duty Dual Wheel Casters: A Comparative Analysis

In industrial equipment mobility, the debate between single-wheel casters and heavy-duty dual wheel casters has been a topic of discussion among experts.

Choosing between these two types of casters goes beyond appearance. It can significantly affect your equipment’s efficiency, safety, and overall performance.

What Will You Learn?

This article embarks on a comparative analysis of single vs. heavy-duty dual wheel casters, delving into their structural differences, load capacities, material compositions, and application scenarios.

What’s More?

Drawing insights from industry resources and expert opinions, we aim to aid you in making an informed decision for your specific operational needs.

With this comprehensive evaluation, we hope to unravel the complexities of caster selection and show why one may be superior to the other in specific contexts.

Single vs Heavy Duty Dual Wheel Casters – Pros and Cons

When it comes to caster selection, it is essential to weigh the pros and cons of each one to avoid choosing a sub-par option.

While both single and dual wheel casters are designed for superior durability, the structural differences between them can greatly impact their performance.

Let’s take a look at the advantages and disadvantages associated with each type of caster.

Single Wheel Casters:

Pros:

Economical Choice: Single-wheel casters often present a cost-effective solution, especially when budget constraints are at play. They typically come at a lower price than their dual wheel counterparts.

Simplified Maintenance: Given their single-wheel design, these casters are less prone to debris accumulation. Unlike dual wheel casters, the absence of additional crevasses ensures a cleaner operational experience.

Optimal for Tight Maneuvers: Their design is ideal for operations demanding a tight turning radius.

Low Initial Push Force: Initiating movement with these casters is relatively effortless.

Smooth Operation: Users can expect a seamless ride coupled with low rolling resistance, promoting efficiency in various applications.

Cons:

- Limited Weight Endurance: These casters can’t match the weight capacity of heavy duty dual wheel casters.

- Not Designed for Speed: High-speed operations could pose challenges, potentially compromising their performance.

- Swiveling Issues under Load: These casters may face difficulty swiveling smoothly when burdened with substantial weight.

Understanding these nuances is crucial in determining the right fit, especially for businesses seeking optimal performance and longevity in their heavy machinery and equipment.

Discover our diverse range of single wheel casters tailored to your specific applications. Find the ideal fit for your needs with just a click.

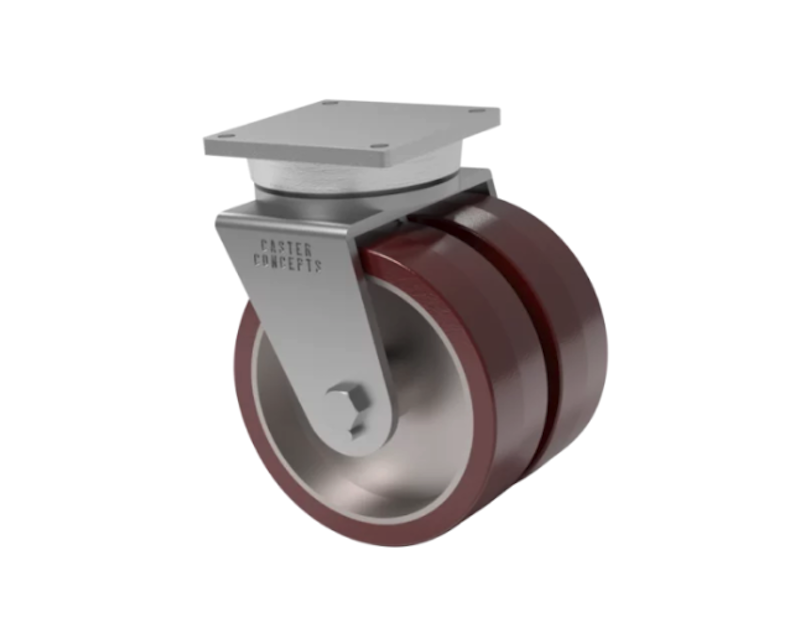

Dual Wheel Casters for Heavy Duty Applications:

Pros:

- Superior Load Capacity: Dual wheel casters for heavy duty applications outshine single-wheel variants in terms of weight-bearing capacity. For perspective, if a single wheel caster supports 3500 lbs, its dual wheel counterpart can efficiently shoulder 7000 lbs. This capacity proves invaluable in space-constrained environments, where weight distribution is crucial.

- Optimal Space Utilization: These casters are adept at hauling more weight without occupying excess floor space, addressing spatial challenges in certain facilities.

- Swift Directional Changes: Dual wheel designs make pivot and change direction easier, optimizing maneuverability.

- Beneficial for Height-Limited Applications: With a selection of smaller wheel diameters, these casters cater to spaces where height poses restrictions. They deliver the highest capacity with the least elevation.

- Floor-Friendly: A notable advantage of dual wheel casters is their ability to distribute weight uniformly, lessening the pressure exerted on facility flooring and minimizing potential wear.

Cons:

- Increased Push Force: Initiating movement with these casters might demand more effort due to their inherent design and weight distribution.

- Higher Investment: Quality comes at a price. Though they offer numerous advantages, heavy duty dual wheel casters are generally pricier than their single-wheel equivalents.

Choosing between the two often concerns specific industrial needs, ensuring operational efficiency while adhering to space and budget constraints.

We at Caster Concepts offer a broad range of heavy duty dual wheel casters customized for various industries.

Built with the latest technology and innovative materials, these casters are designed for superior performance, longevity, and effortless maneuverability without compromising safety.

Click Here to explore our range of dual wheel casters, or check out our online caster configuration tool if you have any custom caster wheel requirements.

A Comparative Analysis – Single vs Heavy Duty Dual Wheel Casters

In a side-by-side comparison, single wheel casters are economical, easy to maintain, and perfect for tight turns.

They excel in providing a smooth ride with low resistance but face limitations in weight capacity and high-speed applications.

On the other hand, twin wheel casters, though pricier, handle exceptional loads, occupy minimal space, and offer flexibility in height-constrained environments.

Their design ensures both agile maneuverability and floor protection.

A Better Option:

If you need to balance load endurance and space optimization with budget factors, giving a slight preference to heavy-duty dual wheel casters could potentially enhance your operational efficiency and longevity, offering better value for your investment in the long run.

Still confused about when to choose a dual wheel caster? Check out our related blog post.

Related: When to Use Dual Wheel Casters

Deep Dive into Heavy Duty Casters with 2000 lbs. Weight Capacity

Seeking robust solutions for demanding applications?

Consider heavy duty casters with 2,000 lbs weight capacity. Our offerings span a spectrum of wheel types, materials, and caster designs, with a diverse range of locking systems and brakes to ensure optimal functionality.

The significance of 2,000 lbs weight capacity cannot be understated, as it caters to rigorous operational needs.

While these cater to loads up to 4,999 lbs, demands exceeding this necessitate exploring our extra heavy-duty (5,000 lbs to 16,999 lbs) and super heavy-duty caster (17,000 lbs or greater) range.

The precision and engineering brilliance behind such high-capacity casters is a testament to the innovations in caster technology.

But what if you need a custom caster wheelset for your applications?

Custom Caster Wheels: Your Solution to Challenging Projects

Do you have a project in mind that requires custom caster wheels? Our team of specialists has the expertise and experience to craft customized solutions tailored to your unique needs.

So, whether your project calls for forged steel or polyurethane wheels, a custom diameter, or a specific braking/locking system, our Caster Concepts team is ready to assist. We’re committed to tailoring solutions to meet your unique requirements.

Distinctive Advantages

In our exploration, we’ve delved deep into the intricacies of caster wheel choices. The heavy-duty dual wheel casters emerge with distinctive advantages, notably in terms of load-bearing capacity and floor protection.

Their superiority in high-demand scenarios is undeniable. When considering robust solutions for demanding environments, the strength of twin wheel casters is paramount.

Should your applications demand the resilience and reliability of these casters, don’t hesitate. Reach out to Caster Concepts for all your heavy duty dual wheel caster needs.