Generative design: nTopology blazing a trail through 3D printing world

One of the most impressive features of the nTopology design application is that it requires substantially less computing power. According to the company’s – and its partners’ – calculations, file sizes can be 99 percent smaller compared with traditional 3D design software.

Traditional, long-established software for 3D design tends to be very memory-hungry and can seriously stress out processors. nTop, on the other hand, can provide the same functionality if used on a laptop as traditional 3D design applications would if run on a supercomputer – because nTop was specifically designed for today’s 3D printing and design requirements.

The way nTop does this is difficult to explain for a non-technical journalist, but essentially, the nTop software does away with such things as extrusion, which is a fundamental concept and requirement in traditional 3D design applications.

Extrusion can be done by clicking and dragging a face or edge of a drawing. So, for example, say if you draw a square on the screen in a traditional design app, you could click and drag the face and it will become a cube.

Sounds simple, but say if the object you are designing integrates multiple shapes and faces, you could end up with a long list of parts and dozens of extrusions, all of which require memory space and processing power.

nTop’s approach is completely different and was built from the ground up to suit the needs of the 3D design and printing industry, especially with regard to generative design element, which is a big part of the software.

And although nTop has all the necessary functionality to enable complete end-to-end design projects, it also integrates with all major traditional and long-established CAD design software applications.

That’s the extent of our technical knowledge, so in order to give readers a deeper understanding, we thought we would interview someone from nTop, and publish an extract here.

Although he has since moved on from nTop, Duann Scott was vice president at nTopology at the time of this interview, and explains in detail about the software and provides an overview of the 3D design and print sector as a whole, as well as related industries.

RoboticsAndAutomationNews.com: Tell us a little bit about nTopology itself for the company.

nTop’s Duann Scott: nTopology is a design engineering software. The company was founded in New York City in, I think, 2015. We have a different approach to making geometry. It’s not traditional CAD, it’s a different process whereby you it’s a computational design tool.

We help engineers and designers solve problems that traditional CAD cannot solve due to geometry issues in existing CAD. We can do very very complex things very easily and we can automate processes. So, often people aren’t designing a single part but they’re designing a process, and the output is parts in the end.

RoboticsAndAutomationNews.com: What’s your overview of the changes that are happening in the manufacturing sector as a result of the emergence of 3D printing?

nTop: Additive manufacturing started off as rapid prototyping. Initially, it was just plastic parts to make prototypes to see how things look and fit and work. Then, the industry moved on to things like jigs and fixtures. Now, as these the processes have evolved, people are designing end-use parts.

And, particularly in metal 3D printing, the material palette has opened up massively in the past five to 10 years. We’re at the point now where you can manufacture super alloys and copper, stainless steel, titanium, and other very high value materials.

Part of the reason for the progress is because 3D printing has been driven by the aerospace and medical industries. So the machines have evolved to a point where you can do very complex componentry, very complex designs with very fine details and fine features.

However, the software that people were using to design for it was designed for traditional subtractive manufacturing, for tooling, for molding, for stamping, and the software could not create the complexity that the machines could make.

So this is how nTopology was really born. It was to unlock that potential of the manufacturing processes by using a different way of approaching geometry. It’s really critical to redesign for these processes because the the cost of machines and materials is still quite high. so to really get the value, you have to design for the process.

This is because if you take an existing machining design and put into a 3D printer, it’s not going to be cost effective. But if you take that design and optimize it for multiple requirements – whether it be the manufacturing process, thermal process, for light weighting, for other functions around acoustics – you can do this simultaneously and then also consolidate multiple parts into a single component and really drive value from the 3 0printer.

So that’s where we are now. People understand that this multi-discipline design process is critical for extracting the value from 3D printing.

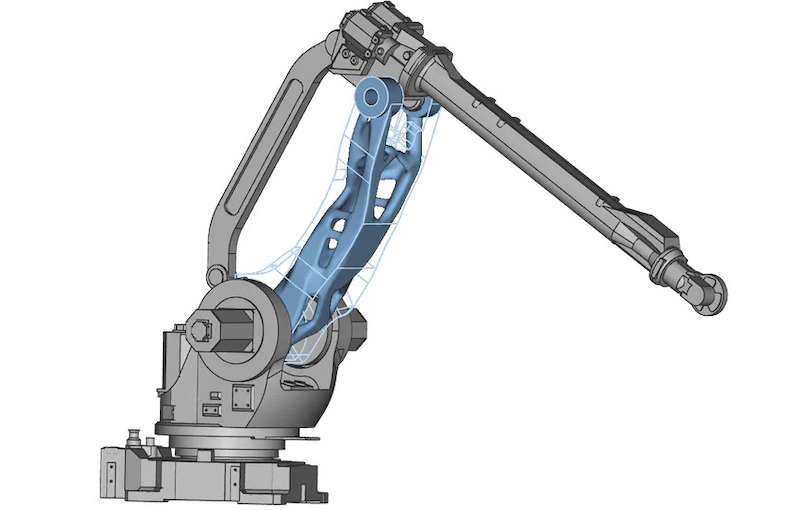

RoboticsAndAutomationNews.com: In other words, 3D printers are so advanced that a new design software application and approach was required. I understand. So give us an example of how traditionally simple parts can be designed with more complexity. Part of a robot arm, for example – like the one pictured on the nTop website.

nTop: We’ve seen some built like this robot arm part, but they are mostly in R&D or for bespoke robots.

So what’s happening here in this design is that the wireframe of this component is the original body designed in CAD from the assembly for the robot – the traditional design of such a component, basically.

We’ve taken that component and we’ve applied simulation – stresses and constraints on the component. And where the stress is, we run simulation on that, and what it’s really showing is the load path of the stress.

The simulation shows the robot moving and lifting things and orienting itself, and we can see the stress as it moves through the component. This helps us discover the places where we don’t need to have mass. If we don’t need it, we remove the mass, so you end up with a more lightweight part.

We can then go do and a secondary process and we can then run the simulation again, and we can then shell the parts to make it hollow, so again we reduce more mass out of the part, and also reduce the manufacturing time.

We run a simulation again and where we find stress we change the thickness of that shell, so the part is thicker where it needs to be and thinner where it does not.

So it starts to sort of mimic the natural process of how a bone might be generated in the human body. So a human bone continually modifies itself based on the stresses that are placed on it.

Then we can go in and do a lattice infill to make it more manufacturable in that you wouldn’t need support structures inside.

So that’s sort of the approach we take. It’s really topology optimization. When you think about generative design, what you’re doing is you’re generating multiple outputs and comparing them to each other.

So we would run a script like you might run overnight, and then in the morning, when you come back to work, you might have a thousand variants of this design . You can compare them to each other based on the mass, their performance, or some other criteria you might have.

So that’s sort of the approach.

We’ve done this for real at Oak Ridge National Laboratory, where they designed some robot arms. It was actually a fully articulated robot that had all of the wiring and any other components built inside of the part as well, so you wouldn’t have any exposed and cables or wiring – it was all really self-contained,

I think the robot was for an underwater application.

So you can do very complex things with this process and with high quality materials.

The other thing we’re doing now as well with partners is not necessarily printing the final part but printing either a sand mold to cast the part or printing sacrificial components for investment casting.

So you could print it in a lower cost polymer and then coat it with a ceramic and then pour metal into it so you have the same known process that’s been around for thousands of years in the end, but just we we’re sending the design in a different way there.

RoboticsAndAutomationNews.com: I would imagine metal parts are either difficult or time-consuming for 3D printers to produce. Are there alternative materials that are just as strong – new alloys and and maybe different plastics and things like that that can do the same job as metals?

nTop: The cost in the metal printing is in the amortization of the machine cost, which can be expensive. But the actual quality of the materials is very good.

As i said before, what we’re seeing people start to do is to print polymer parts and cast them, or to print sand molds. That is a cheap way of doing it and there’s also some processes where there’s high quality polymers and also carbon fiber layouts on parts as well to make them stiff and strong.

RoboticsAndAutomationNews.com: What percentage of the potential market has 3D printing captured? I mean how widely used is 3D printing now compared to how widely it could be used in future?

nTop: I’d say it’s a tiny percentage at the moment. As I mentioned before, what’s leading the industry is aerospace and medical. So in medical and dental, it’s pretty much like if you aren’t adopting additive manufacturing then you’re falling behind.

Spinal implants, knee reconstructions, bone plates and other aspects are all very much leading the way because they’re small, they’re expensive, and they’re custom to each customer. The customization is critical to make sure that you don’t put the same implant into an eight-year-old child as you would a forty-year-old man who’s 240 pounds.

So you always modify the design for that particular person, and in dental everyone’s teeth is different so a lot of scanning to manufacture is going on, and that’s going in both metal and polymer.

So medical and dental are really leading it. The adoption’s really strong, and we start to see it expanding as people learn more about the process. And the cost of the machine and materials has been coming down over the years.

RoboticsAndAutomationNews.com: You also mentioned aerospace before. How about automotive?

nTop: Absolutely, yeah, we do have customers doing electric vehicles. For space and flying, I don’t think I can mention their names but, yeah, every ounce of weight that you save reduces the weight of the structure required to carry loads and also the battery power to to run it. So every everything you do that reduces weight increases range and so lightweighting is critical really.

One of our customers – Cobra Aero – started off designing the engine head for the single cylinder engine that they run for the UAVs (unmanned aerial vehicles) that they make.

Cobra started off with us just trying to consolidate parts: so, taking three parts and combining them into one. From there, we also worked with them to lightweight the head of the engine using lattice structures. And also cooling the component using lattice structures.

We did this all based on simulation. So we can take the pressure map from the engine, the heat from the engine, and we’ll use that to modify the lattice structures to optimize it and and make it way more efficient, way lighter, and use fewer components.

Like combining three components into one so there’s no assembly, there’s no fasteners, there’s no gaskets – it’s less maintenance as well, and we can also do things like attenuate the acoustics to reduce the sound, which is critical for a drone that’s trying to not be seen.

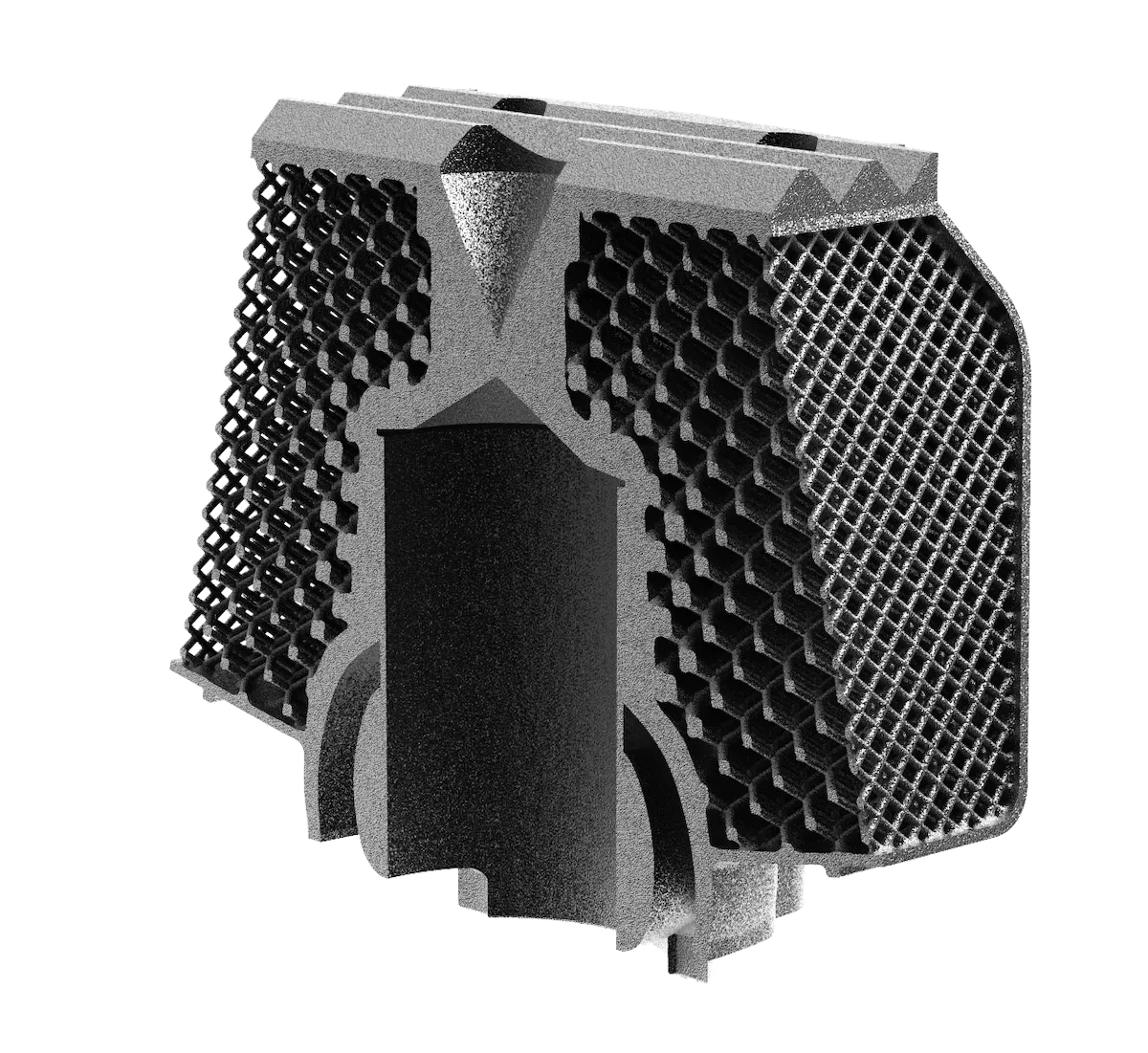

Lattice structures allow you to to modify the behavior of a material without changing material. It’s used a lot in additive manufacturing, Designing using lattice structures means you can make a component crumple in a certain way, or absorb energy, or reduce its mass, or change the way it flexes.

We use it in polymers. You see it in padding and seating for cars, and also an American football helmet we designed.

The helmet was designed for NFL players. There’s a number of helmet companies using this design now. But we won a grant from the NFL to develop helmets to stop concussions using lattice structures to help absorb energy and stop the twisting of the head during impact.

So you can really change the way your material behaves using a lattice structure and that’s what we call the meta materials or architected materials.

RoboticsAndAutomationNews.com: So you provide software and related consulting. Is your software available through the cloud?

nTop: We’re purely a software company. We developed the software from the ground up. Existing CAD systems are based on taking drafting or drawing and putting it into a computer, and were mostly developed in the 1980s.

The kernel underlying all of that, the way the geometry is created, is a b-rep (boundary representation), and because it’s developed so long ago, it was developed for single threaded computers, and there’s inherent issues in complexity, which was never ever conceived of when doing geometries this complex with a CAD system.

What we do is different. We have a different way of creating geometry. It’s basically a mathematic equation and all we’re doing really is using a formula to define a product, so we can do something very complex, and the file size for this in nTop would probably be 160 kilobytes, whereas if you tried to do this in a traditional CAD, it would be several gigabytes.

You couldn’t do anything in real time like this in a traditional CAD system.

Ours is a purely a mathematic equation which describes geometry. We also have what we call field driven design, which is where we can use any data to drive the way a geometry behaves, whether it be simulation data or empirical testing data or just other geometry to help define the way the geometry behaves.

So, for example, we designed a prosthesis where we’re adding a surface structure to make it stronger. You can see it on our website.

Also, you can see on our website , you see a trainer design. You’ll see a pressure map from somebody putting weight on their foot . We modify the lattice density based on the the force going into the the shoe sole, so we can make it denser to absorb more energy where there’s more pressure, and make it sparser where there’s no pressure.

So we can make it lighter. We see people doing this to optimize a shoe for someone with diabetes. If they’ve got some issues with their feet, we can help relieve pain and make a custom shoe solve specifically for them.

This is all possible because the underlying geometry complexity is not a problem for nTop.

Often, the parts are so complex that, if you are using traditional CAD, you might need to use other software for downstream processes, whether it be simulation, or for manufacturing. The CAD app can’t handle it on its own.

We have our own internal functionality for simulation and for manufacturing. We often send manufacturing data direct to the 3D printing machines because any software which is sort of in between us and the machine can slow things down.

Our software is completely local. We don’t run on the cloud yet. This is because most of our customers are in aerospace and defense and medical – and they’re not really, in most cases, ready to have their designs up on the cloud. There’s too many security issues.

We can conceivably make nTop available as a cloud app, and we do have people running it in servers. But, as it stands, the software is local, and because we’ve optimized for multi-core CPUs and GPUs, engineers just run our application on a laptop.

They’re not running a supercomputer to make and simulate these really complex designs because nTop is so efficient in the way that it describes that modified geometry.

Watch the complete interview on YouTube or below.