Getting your warehouse holiday-ready: How technology can help you ride the tide during the busiest time of the year

By Pieter Feenstra is the CEO of Addverb Technologies’ EMEA region

The holiday season is right around the corner and hype is in the air. With customers in their deal-hunting mode getting ready to score the best deals, and businesses offering competitive discounts for limited periods to trigger a sense of urgency, it sure is the busiest time of the year.

Customers are starting their holiday shopping earlier than usual this year to spread their spending across more paychecks to minimise financial strain.

This also means that those who facilitate the smooth running of operations during this peak season are under considerable pressure to meet growing demands, largely propelled by e-commerce sales.

Especially for warehouses, it can be challenging to be flexible and keep up with overwhelming volumes of orders to process. Complex decisions need to be made and efficient plans laid out.

Let’s explore a few areas to focus on while preparing your warehouse for the holiday season and reimagine a few scenarios with innovative technology that can take your competence to the next level.

To hire or not to hire, and the labour shortage conundrum

One of the most pressing questions warehouses face during peak holiday season is whether or not to hire temporary seasonal workers to manage the additional workload and also how many workers to hire. This decision is usually based on metrics such as past experiences, order projections and productivity targets.

By gauging the capacity of the current staff and how many shipments each individual can handle, against the number of orders or shipments that are supposed to be processed during the peak season will determine how much additional help is needed on a daily basis.

There are significant advantages to hiring seasonal workers, like boosting employee morale during the most stressful time of the year where regular employees would very much appreciate some time off without having to worry about keeping the business running.

Seasonal hiring also provides an opportunity to get to know potential permanent hires if you’re thinking of increasing capacity in the future.

On the flipside, there are some cons to consider. Most importantly, the persisting labour scarcity poses significant bottlenecks for companies to find people to work in warehouses.

Especially in the Netherlands, the number of vacancies in the second quarter increased by 44 percent as compared to the previous year. During the same period, there was also a simultaneous decrease, down to 31 percent, in the number of people availing unemployment benefits. This makes seasonal hiring practically difficult, to begin with.

Apart from this, seasonal hiring is expensive. Right from recruitment announcements through advertising, recruitment processes, wage expenses, benefits and so on.

Additionally, the new hires need to be trained on specific warehouse skills and procedures to be inducted into the warehouse routine and this includes legally mandated general safety instructions that need to be completed and accounted for.

Supervising new, inexperienced members may also chip away valuable time from experienced staff, indirectly taking away their focus from order fulfilment. Most importantly, new recruits are also prone to making mistakes due to their lack of experience.

A busy working environment with more people working in close proximity, with members who are not fully familiar with the nature of work and its contingencies is ever the more conducive to accidents.

As they are yet to hone their instincts to rightly anticipate potential work hazards and their own threshold for exertion, seasonal employees might find it difficult to perform efficiently, yet safely within the relatively limited margin for error.

Given how the holiday season already demands a lot of different things to be dealt with, complication regarding human resources only adds to the pile.

As we go on, we’ll take a closer look at the many interesting ways in which technology can provide a more sustainable and long term solution for this problem.

Not only does it help save the trouble of hiring a number of under-experienced staff to make up for capacity requirements, robotics, for instance, offers a flexible mode of operation to accelerate the warehouse workflow without having to expose their valuable human resources to avoidable hazards.

Analysing pick paths and determining optimal routes

It is no surprise that the holiday season at warehouses involves a lot of things happening simultaneously. The dynamic combination of changing customer requirements, introduction of a plethora of new items everyday and the challenging nature of seasonal demands no longer allows warehouses the luxury of being merely reactive.

Neither can they afford to be static anymore. If not organised well, the situation could very well wind into a confusing mess.

This means that determining the most optimal routes for pick paths is indispensable to smooth operations. One way to ensure this is to make sure that the right products are placed at the right places and the design of optimal paths should facilitate optimal forklift movement.

It might seem overwhelming, however, technological intervention proves immensely useful for such complex tasks. Take the case of smart forklifts: by plotting the history of forklift movements on the warehouse layout, the bespoke software provides valuable insights on rotating patterns and identifies locations that may otherwise be hidden, inadvertently causing loss of productivity.

Similarly, heat map analysis makes it possible to gain insights into any changes of various classes of items and their storage pattern subsequently. This improves safety and performance by suggesting optimal routes on a real-time basis.

Maintaining accuracy

Getting the right products can be challenging with larger volumes to be processed within limited time frames. Optimising storage and decluttering floor space, to a great extent helps reduce potential mixups.

However, an innovative technology like Pick by voice increases the accuracy of operations by 35 percent, reducing the chance of picking the wrong item due to lack of concentration or other challenges.

The operator is given a smartphone enabled with a voice based app, powered by Natural Language Processing along with a headset to receive audio instructions and deliver voice confirmations.

The picklist is pushed to the system, directing the picker to a specific location in the aisle where he is to perform the picking operation. The picker then confirms they are in the right location by reading out a specific check digit.

Following this, the system will instruct on the required quantity to be picked and the picker confirms it once done. The process is repeated. An added advantage of this technology is that the voice-based system also optimises the pick path to ensure that the operator has to cover only the minimum distance.

Importance of trend analysis and research

It’s worth stressing that you cannot improve on something you cannot measure. In the context of warehousing, it becomes extremely difficult to know how much space you need to free up without having a solid idea about how much inventory is arriving on a regular basis.

This is where projections and predictions come handy. By employing Machine Learning (ML) and Artificial Intelligence (AI) it becomes possible to arrive at order projections for the season based on previous years’ trends and the current year’s performance.

Critical exercises like stockout prediction and demand forecasting using innovative technology enables warehouses to prepare for the peak seasons and manage well.

ML and AI, in many ways, can revolutionise the modern-day warehouse experience by improving the efficiency of the warehouse and at the same time relieving staff from strenuous work.

Especially in the case of companies with multiple warehouses, ML can remarkably help improve inventory optimisation- by considering multiple independent variables that could cause errors or delays in inventory management and providing appropriate suggestions and solutions to manage stock efficiently.

ML can also help calculate the expected work completion times for a given task by analysing streams of minute operational data, without the need for upfront investment or engineering, but instead make the data accessible through a number of sources like mobile devices and automation systems.

The use of robots and warehouse automation to further reduce the dependency on labour

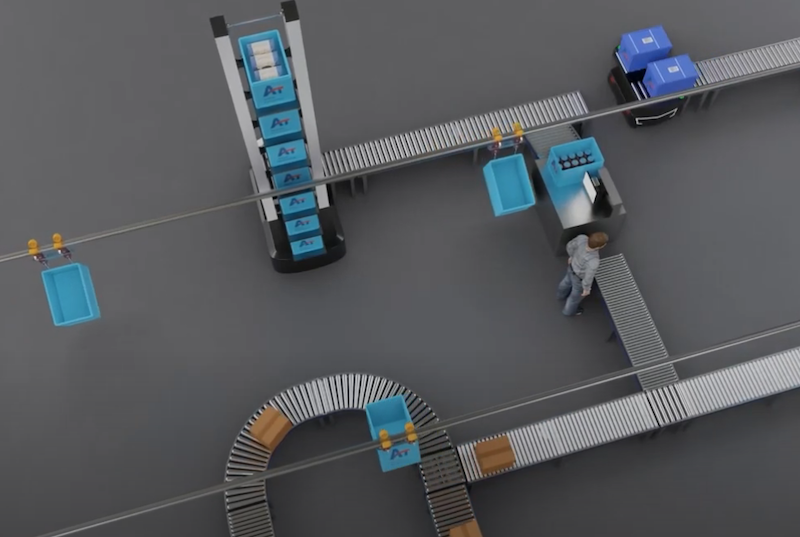

A flexible sortation and order consolidation system works phenomenally well during seasonal peaks, given its capability to handle a diverse variety of products with speed and precision.

Consider a highly innovative goods-to-person picking system like Addverb Veloce, a multi-carton picking mobile robot used to store and retrieve cartons, cases and crates. By following a QR-based guided path to navigate around the warehouse, the robot only picks those cases that are required by the operator, and not the whole rack.

It can carry up to eight crates and interact with various automation systems such as picking stations, AMRs, conveyors and ERP softwares.

Similarly, robotic sortation allows batch-pick operations where a single operator picks a whole lot of items, compiling a batch of orders at a time, thereby translating to a huge boost in productivity.

In effect, this helps fulfil orders quickly, reducing both the repetition of trips to the same location and the possibility of congestion and accidents. Once this is done, the robots can do the remaining tasks toward the order fulfilment.

During peak seasons, just by adding additional robots, warehouses can meet the rise in demands without the hassle of scouting for and hiring a seasonal workforce.

Best available technology

Being prepared not only makes things easier during stressful times but also positively impacts the bottom line by giving the company a competitive edge over the others.

At a time when every business strives to get the lion’s share of holiday sales, it is imperative that your warehouse is well stocked and equipped with the best available technology to ensure that customer demands are met promptly and accurately, making the holiday season a truly delightful experience for everyone involved.