RapidDirect Introduces Automated DfM Feedback Tool Can Help Optimize Your Part Design

RapidDirect’s automated DfM feedback tool offers quality manufacturability tips for your parts production.

This improved automated DfM tool provides a reliable analysis of your parts design for crucial issues that can affect their manufacturability or attract additional manufacturing costs. Read on to learn about the new DfM feedback tool, how it works, and its advantages.

What is Design for Manufacturing (DFM)?

Design for manufacturing (DFM) is a process used to design components for easy manufacturing to produce products with the best quality at a cheaper rate. Usually, this process involves simplifying, optimizing, and refining the product design.

It helps manufacturers to detect and avoid errors or discrepancies that may occur. In addition, the acronym DFM is sometimes used interchangeably with DFMA (Design for Manufacturing and Assembly). This is to show that DFM is not only important for manufacturability, it is also vital for the eventual supply of the components.

RapidDirect’s Automated DfM Feedback Tool

RapidDirect’s automated DfM feedback tool provides a complete overview of the design features and a breakdown of their machinability. The report comes with a CNC instant quote to give customers direct insight into the manufacturability of their parts as they process them for production.

How Does it Work?

To place an order with RapidDirect, you must upload a CAD file on the online quoting platform. This quoting engine will automatically analyze the uploaded CAD model and calculate the manufacturability of each part feature. It compares the design with the data from their rich manufacturing database.

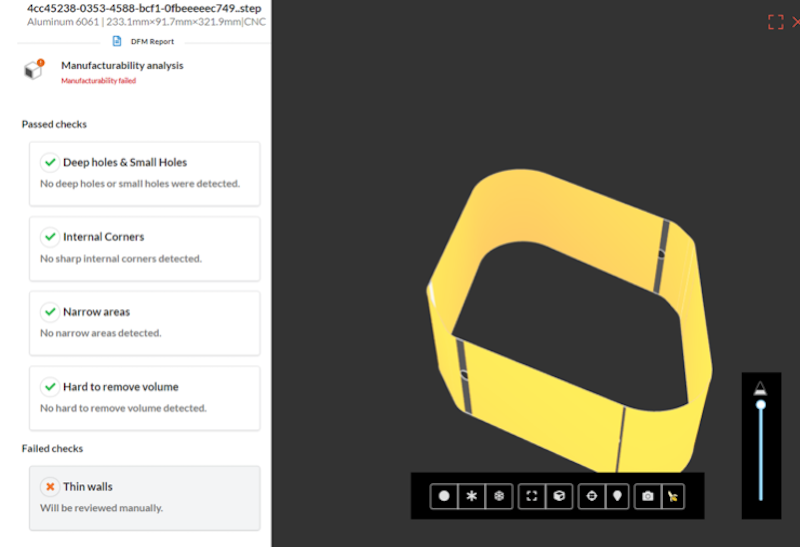

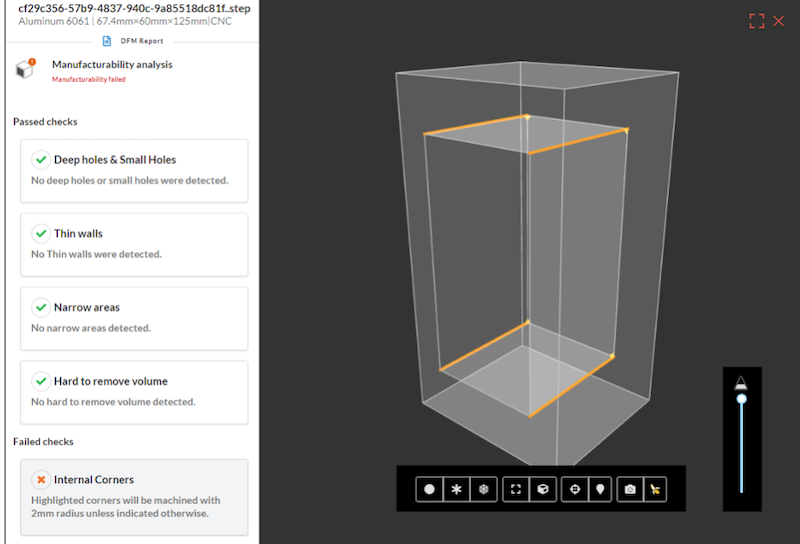

The analysis takes seconds to complete, after which you receive a user-friendly, three-dimensional visualization of the part and design feedback. This feedback tool offers an essential assessment of the part, explaining several design elements like radius or hole size, grooves, internal corners, wall thickness, and others.

Green check marks mean the CAD model or design you have uploaded can be manufactured with their CNC machining equipment. You get red check marks if you need to change your part designs.

Once the DfM feedback feature approves your part for manufacturing, you can proceed to the next stage of the online ordering process. You’ll receive a quote, lead-time estimate, and parts manufacturability guarantee.

The DfM Feedback In-Depth

Thin Walls

RapidDirect’s DfM tools identify walls thinner than a material-dependent threshold. However, cases like such require time-consuming cutting operations or different manufacturing processes that could increase the production cost. Therefore, a modification of the design is recommended to economize the costs.

Thin walls are almost impossible to machine because these features can break due to the cutting force while machining. The recommended minimum wall thickness for metal is 0.8 mm, while for plastic is 1.5 mm. In addition, all features must bear a height-to-width aspect ratio lower than 4. Any wall that exceeds these standards will require special and more costly tooling or EDM.

Hard to Remove Volume

Your parts become more expensive to manufacture if DfM tools instantly detect volumes of materials that are hard to remove using the standard 3-axis mill. Hence, this allows you to update your design before manufacturing your parts. Undercuts are an excellent example of such volume.

Standard end-mill cutting tools cannot machine features like undercuts, regardless of how the parts are rotated. Special cutting tools such as V-shaped, T-shaped, or lollipop-shaped ones can help machine undercut features. Furthermore, you will need to use a 5-axis CNC mill to machine tools with no standard geometries from scratch. As a result, it increases the cost of production drastically.

Internal Corners

A 2 mm radius will be used to machine all detected internal corners on your parts to minimize the cost of production unless stated otherwise in your technical drawing. Their DFM tool will search for any inner corners that are impossible to machine with standard end-mill tools whenever you upload your parts. You must utilize a more expensive process like EDM to create these features. You can make the EDM an ideal requirement in your technical drawing for your parts.

Deep Holes and Small Holes

The DfM tool detects deep holes and small holes in your part’s geometry which are hard to machine instantly. As a result, you are advised to update your design to reduce production costs.

Narrow Areas

Narrow regions usually require extra time and specialized tools to machine, resulting in more costs. However, the manufacturability feedback helps improve tour design and create better parts before production begins.

The Advantages of RapidDirect’s Automated DFM Feedback Tool

These are some of the benefits of using RapidDirect’s automated DfM feedback tool.

Get Error Detected in the Design Stage

The primary purpose of the Design for Manufacturing (DfM) is to detect errors and correct them so you can have a good and functional end product. If you fail to address issues/errors at the design stage, you will likely have a product that doesn’t fit its purpose or intended environment after assembly.

These situations occur when designers fail to think about how their products will be produced during the design phase. The DFM analysis allows designers to incorporate workable CNC machining design tips to improve their products.

For instance, suppose multiple parts are involved in a product’s construction. Such a product needs to fit well when assembled so that there won’t be any gaps or overlapping between the pieces, which could result in problems along the line.

Fast Turn-Around Time

The DfM process helps to speed up the entire manufacturing process making the part suitable for the selected manufacturing equipment. For instance, if the part fits nicely into the machine’s die, the cutter can do its job more efficiently and manufacture finished parts without delay.

Furthermore, the DfM process increases the chances of automating the production of parts. After automating the process, there is less human oversight.

Reduce Cost

Design for Manufacturing (DfM) helps to ensure your parts are effectively and efficiently made with reduced cost. Also, it determines the most sustainable and cost-effective material for your parts production.

Designing a product that you can produce efficiently means it will be easier for your manufacturing partner to produce it at a more reasonable cost. As a result, you can offer your products at an affordable unit price. When your products are very affordable, customers will tend to demand more. Therefore, the higher the demand of customers, the more profit you make.

Efficient and Versatile

The DfM feedback tool is an efficient and versatile tool that assists you in transforming your ideas into quality products. Also, it helps to achieve the lowest production costs while using the most efficient manufacturing processes within the fastest lead time.

RapidDirect offers the best manufacturing solutions to support all your custom part requirements. However, it would help to understand how the process works to get the best results.