Micromolding Service for Droplet Microfluidic Chips Market

Droplet microfluidics is a recent trend of laboratory automation technologies, which allow scientists to explore the biological world at an unprecedented resolution and throughput.

The new infrastructure is powered by innovative instrumentation, software as well as the consumable reagents and chips. In this context, plastic chips play a key role in enabling these applications, as they ensure a consistent and scalable droplet production.

What are the microfluidic chips?

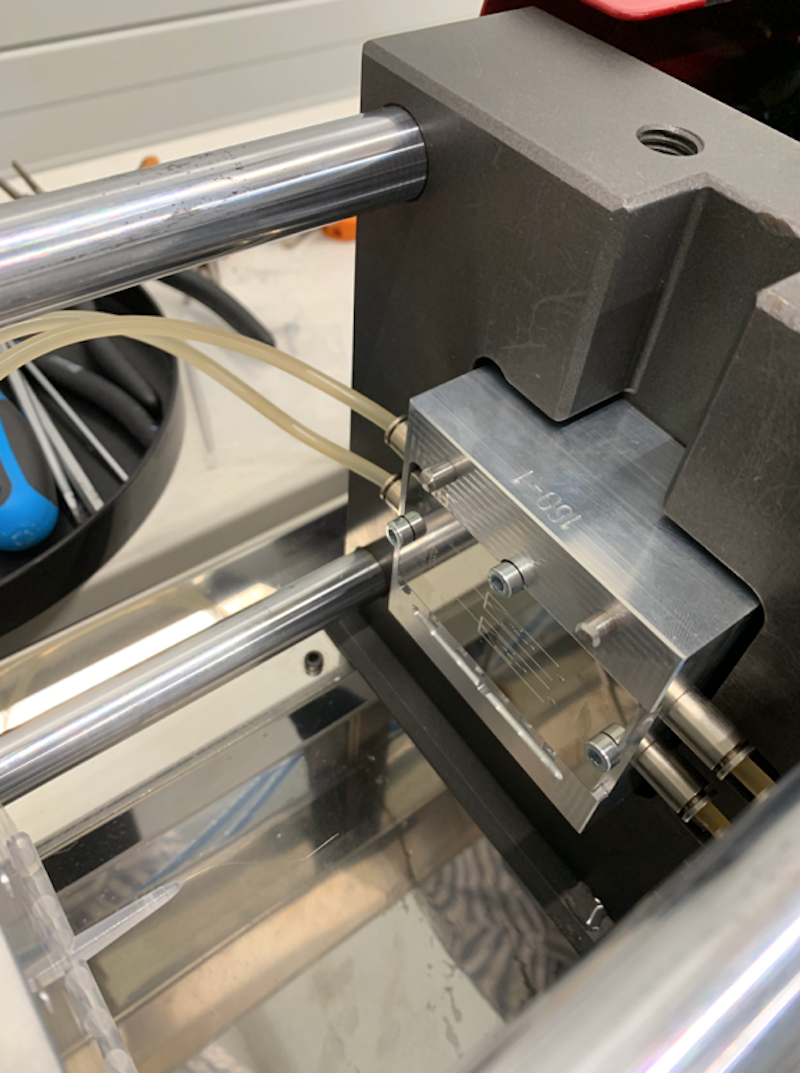

At the foundations of droplet microfluidics are the chips used for high-speed droplet generation, injection, splitting, merging, mixing and storing. However, specialist micro injection moulding knowledge is required for producing chip features with micrometer resolution.

Material science expertise is equally important as chosen plastics need to be compatible with fluorinated oils and biological analysis workflows.

Finally, mechanical design is also important, as plastic chips feature a combination of microscopic features defining microfluidic functions, in addition to the macroscopic chip features like snap fits for assembly and liquid containers (wells).

After microfluidic channel designs are tested, the chips need to be produced at medium or high volumes, which is where Micromolds steps in with specialized injection moulding services.

Technical challenges

The main challenge in making chips for droplet microfluidics is the extreme tolerance requirements for injection tooling. Micron precision is not practically achievable using regular machining and this is addressed using specialized tooling inserts, which may be produced using pulsed-laser processing or electrochemical methods.

Micromolds expertise is the ability to design these hybrid injection moulding cavities, which combine the micro and macro fabricated tool pieces. Getting the design right makes it possible to reach accurate feature alignment, as well as avoid the fatigue of tool pieces during the process.

Micromolds are able to optimize chip surface flatness despite the tendency of sink marks to be caused by the presence of diverse chip wall thicknesses. Furthermore, the high aspect-ratio chip walls must also be able to support ejectors, for efficient chip demoulding steps.

By tuning process temperatures and optimizing ejector geometries Micromolds were able to efficiently produce microfluidic chips with intricate geometries.

Chip production

Micromolds are excited to participate in the development and production of droplet microfluidic tools for the life science sector.

Dominykas Turčinskas, CEO of the company, says: “We constantly grow with our customers by pushing together on the technical limits of plastic chip designs and enabling new applications, which finally contribute to modern biological research and human health.”