How Additive Manufacturing Works and Provides Benefits

Additive manufacturing is known as 3D printing. Computer-aided programs are used to create 3D objects.

Additive manufacturing is getting popular nowadays. It is a very cost-effective process to design the objects.

Objects are designed with the help of materials such as plastic, ceramic or metal powder. After the design, these printing objects are assembled with heat or a laser beam.

In the following article, I will talk about the working of the whole additive manufacturing process and its benefits There is the following process by which you can accomplish the additive manufacturing. Let’s discuss this in detail.

Use of Computer-aided design software

As you know there are different types of computer-aided software in the market that create feasible and valid designs.

I will tell you about the software that professionals are using to design 3D objects in the additive manufacturing process. With the help of computer-aided design software, large scale offers unprecedented speed can be achieved.

AutoCAD software

AutoCAD has been used for many years in the market. It is the favorite tool of designers. You have listened to it many times. It is used to create a different 3D design in the manufacturing and designing industries.

In AutoCAD, a designer creates 2D with the help of different lines and dimensions and then converts them into a 3D design.

Autodesk 3D max

It is used to create 3D models. Every design has a different option by which you can change the objects. It has a material edit command by which you can edit the material and maps.

Creo element

This software is used to complete dimension calculations during the additive manufacturing process.

It is a solid modeling application that runs on Microsoft windows. It is widely used across the globe for the modeling and calculation of objects.

SolidWorks tool

SolidWorks is a solid modeling and computer-aided engineering application. Millions of engineers are using this application. It is popular in industries and has a wide range of engineering features.

Simulation technique

Once you have completed the design with help of different computer-aided design tools, then it will go through the process of simulation. In this process, a 3D design is tested by the simulation computer technique.

These techniques determine how the design is effective and resemble the real world. You can check whether it will work in the future or not.

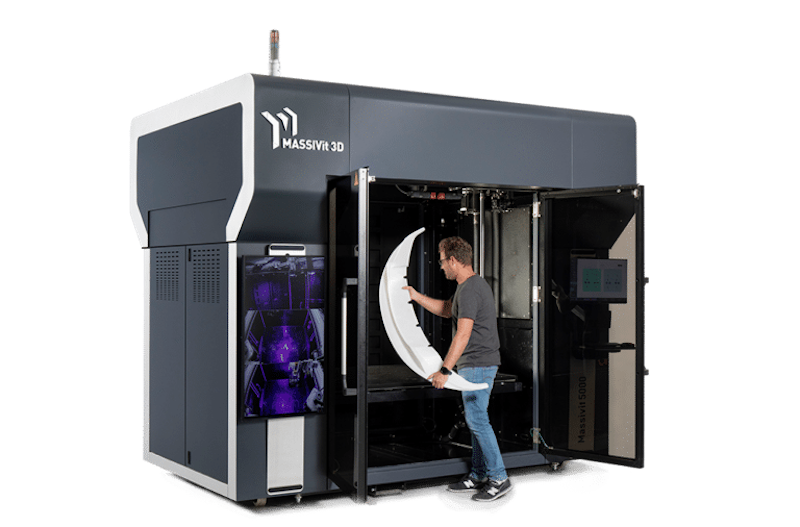

Process of printing

The following two printing techniques are used in the printing process commonly.

1. SLA printing technique

Stereolithography is a 3D printing technology used for creating models, production parts, and prototypes in different layers.

In this printing, the photochemical process involves light that causes chemical monomers and oligomers to form polymers.

3. FDM printing technique

Fused deposition modeling is a technique in which the melt extrusion methods is used to deposit filaments of plastic according to the specific design and model. It is similar to 3D printing. it is a very useful technique for 3D printing. It is applied layer by layer.

Evaluation

Once the design is ready now the evaluation process starts. In this process, you evaluate the whole model.

You remove the extra material from the model and can make it accurately according to the design. You separate the additional parts from the model. You make any change in this process.

Benefits of the additive manufacturing

There are many following benefits of additive manufacturing.

Cost-effective

If you want to manufacture any design you know it is very costly. But if you are doing the things with additive manufacturing, these are inexpensive. Because printers and materials used in the process are not so expensive.

Prototype is effective

Prototype saves you from the big loss. If you are making the prototype then you are in the safe lane.

In the additive manufacturing process, you first make the prototype model before doing anything. You can examine the whole thing before converting it into the complete.

So, this technique is very effective and efficient in additive manufacturing. It also saves your money and time.

Little waste of the material

In the additive manufacturing process, you have to make the design layer by layer. When you complete the one layer then you start the other. In this way, little waste of material and energy occurs in the process.

On the other hand, in a traditional design, you have to lose material costs but, in this process, you can save money and material.