Advertising agency creates robotic system for high-speed filmmaking using RoboDK

Chile-based advertising agency EngamaDos has developed an accessible robotic system to create high-quality slow-motion shots for advertising videos.

Combining RoboDK’s programming software with an industrial robot, the system is more affordable than existing solutions for robotic filmmaking.

Robots have become an increasingly common tool for creating slow-motion video shots for food and beverage advertising.

With a high-speed camera attached to the end of a robot, shots are faster and much more precise than with a human camera operator.

These systems allow filmmakers to create more engaging videos of food and beverages. However, the high cost of the robotic systems can be restrictive, especially for companies based in low GDP countries.

EngamaDos, a creative advertising agency in Chile, has built a robotic system that is cheaper and more accessible than most commercial systems.

Creative consultant Xavier Sanchez says: “There is a lot of demand for these types of shots. I shoot with the robot around 4 times a month. We use them for food, beer, and beverage companies. Our clients include Nestlé, Coca Cola, and Nacional Beers.”

How robots took over high-speed videography

Slow-motion shots are common in video advertising. Mouthwatering images of fresh pizza dough spinning through the air, close-ups of water droplets running down a cold bottle, or sizzling steaks on a grill excite our senses and make us appreciate the products.

This type of shot involves complex series of coordinated motions that are not easy to achieve. A chef performs a fast movement such as cutting an onion in two or sharpening a knife. These motions are often too fast for even the human eye to distinguish clearly.

The conventional way to create such shots is for a human operator to move the camera by hand. However, this is very imprecise and the camera cannot be moved quickly.

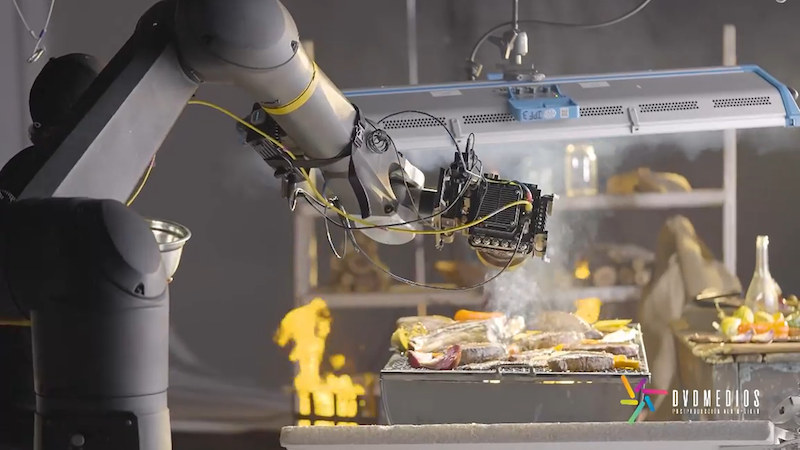

Over the last 5 years, many videographers have begun to use industrial robotic systems to coordinate such complex motions. A high-speed camera is attached to an industrial robot arm. An electronic control system synchronizes the camera motions with the lighting and other motors.

In the blink of an eye, the robotic system moves the camera with absolute precision and repeatability. This allows filmmakers to focus on perfecting the more organic aspects of the setup, such as the movements of the food, flames from the cooking medium, or steam coming from the food.

The problem of high-cost robotic filmmaking

Up until now, most existing commercial systems for robotic filmmaking have been inaccessible to all the largest companies.

Sanchez explains: “We first saw a similar system in 2016. But, the price point was very high. For me to be able to deploy such a system in a low GDP country like Chile, it needed to be affordable enough for people to rent it.”

The team at EngamaDos decided to explore how they could achieve the same level of high precision with a robotic system they had built themselves. This would open up the technique of robotic videography to many more companies.

How the system works

The system is based around a Stäubli TX90XL industrial robot, a Raspberry Pi embedded development board, and RoboDK robot programming software.

Sanchez explains how all these components fit together: “With the Raspberry Pi, we controlled the triggers, lights, and external motors.

“This prevents damage to the system or the environment and synchronizes all the FX. RoboDK is easy and intuitive to use with nice support. It is a really friendly development environment.”

By using RoboDK, the team’s system is easy and quick to program. This allows them to update the precise motions of the camera on the fly during the shoot.

What’s next for robot filmmaking at EngamaDos

EngamaDos has seen great uptake of the robotic system by their customers. A recent project for Chile-based Melt Pizzas, for example, featured highly dynamic slow-motion shots and contributed to the company’s brand image as a disruptive, challenger pizza brand.

They now plan to increase the speed of the robotic system.

Sanchez says: “Next, we plan to add a 7th axis to the system to move the robot faster. This is hard to achieve as the robot is 200 kg and we need it to move 6 meters per second with complete precision.”

This upgrade will allow for even more impressive slow-motion shots and the extra axis will be easy to integrate with RoboDK.