6 Trends in Process Automation Changing How Cars are Made

Process automation has had a significant impact on how cars are made. From the early days of Henry Ford’s simple conveyor belt production lines to modern advances in AI and robotics.

Moreover, with EVs and self-driving vehicles, you can expect new applications for process automation. Additionally, the intricacies of modern EVs require new automated tech that needs to evolve. As a result, manufacturing and automation are constantly changing.

Advanced 3D Printing Technology

You have undoubtedly heard of 3D printing technology. Like something from Star Trek, you can create real objects from a machine in your home. Of course, the applications are limited to single pieces, and the tech is in its infancy.

Nevertheless, improvements are being made all the time. Furthermore, you can use many different models, resins, and materials when printing an item, each suited to a specific task.

However, where 3D printing excels is its accuracy of simple parts. For instance, you can print them instead of buying high-quality truck rims for model cars.

Clearly, if you can 3D print rims for models, then why not full-scale production vehicles? Right now, manufacturers and consumers alike are printing parts for cars.

However, replacements are limited items that do not need to pass safety checks at the moment. For example, you can print cup holders, dials, and knobs.

Additionally, the costs are higher than they need to be for mass production. However, experts predict that 3D printing technology will improve enough within ten years.

Which will be more useful as we shift from mechanical engines to non-moving EVs.

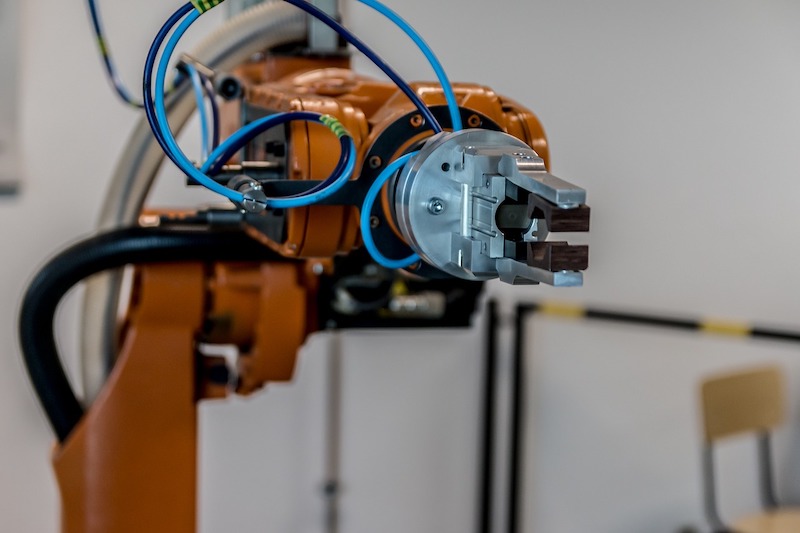

‘Cobots’ are Changing How Cars are Made

At Volkswagen plants alone, each one contains 2,200 robots for automated vehicle manufacture. Robots play an integral part in vehicle manufacture, doing everything from painting and welding to handling hazardous materials and accurate assembly.

Unfortunately, they are so good at their jobs that they have replaced many skilled workers over the past 50 years. You might even be one of them.

However, you need not fear the robot uprising, as they are being used in a better way to assist skilled humans rather than replace them.

Known as “cobots”, advancements in robotics technology and machine learning mean you can teach a machine to aid in manufacturing. Rather than programming, you show them the task you need to do, and they learn how to do it.

This means they are safer and easier to work with. For example, robots are usually fenced off and off-limits because of their hydraulic power.

On the other hand, Cobots are designed to work with you in the same space. Common uses for cobots at the moment include doing repetitive tasks while you get on with more pressing issues.

The Evolution of Artificial Intelligence

From your smartphone to your home heating system and everything you do online, artificial intelligence (AI) is everywhere. Rather than the dystopian robotic uprising from movies like The Terminator, AI is there to assist you.

For example, you probably have an AI-assisted car for tricky parking. In short, there is almost nothing modern AI cannot do, and it is getting better all the time.

For instance, we are on the cusp of automated self-driving cars that operate a vehicle more efficiently than a human. Like many industries, AI is driving automation in manufacturing.

One of the most practical uses for AI is increasing the efficiency of supply chains. AI is being applied to many industries due to humans’ inadequate management of supply chains.

AI can predict shortfalls and change manufacturing protocols based on complex calculations. However, AI can expand beyond plant operations. It can also assist you on the shop floor.

Exoskeletons are an example of AI that benefits workers and maximizes safety. They are designed to assist with heavy lifting, but AI sensors adjust your technique to prevent injury.

Integrated Manufacturing Methods with EVs

The evolution of the car as we know it is happening at a lightning pace. The electric vehicle industry is rapidly changing the car manufacturing industry itself and process automation along with it.

Because there are no moving parts in an EV drive train, there will be no need for outdated robotic assembly. Therefore, new, more advanced machines are required, or you will need to repurpose older ones.

However, newly integrated manufacturing methods and automated processes are in the process of becoming standard as the demand for EVs grows.

The technology in electric vehicles is more computer than an engine, with advanced features like:

- Connectivity to the Internet of Things (IoT)

- Hydrogen fuel cells

- Adaptive lighting

All these features require precise and safely manufactured parts to pass rigorous inspections. Advancements in automation such as machine vision use various inspection methods such as x-rays and infrared digital video signals to find defects with parts that you cannot see with the naked eye.

Therefore, production time is decreased while precision is increased.

How Cars are Made will be Data-Driven

Data is at the heart of the modern business, from the home blogger to multinational corporations. Analysis tools allow you to capture data for anything, which in turn lets you make decisions based on the data you have in front of you.

Of course, data itself is useless if you do not know what to do with it, But under an expert eye, data is one of the most powerful things in the world.

Modern computers can process large amounts of data in a very short amount of time. Moreover, process automation will benefit from data input for product output.

Data can come from many sources, and your manufacturing plant can react in numerous ways based on connectivity.

For example, suppose a client wants to customize a new Ford with trims and extras. The Ford sales system is connected to your custom parts factory.

In that case, data entered by the sales team or even an AI ChatBot is sent to your automated processing plant to make the parts requested by the customer.

Your automated system kicks into action from data entered, with no human input, only data sent from one connected machine to another.

The Autonomous Vehicle Revolution

Process automation is undergoing a revolution in vehicle manufacturing. Where it once was confined to the manufacturing plant alone, automation will soon extend into the world.

We are on the edge of a breakthrough in self-driving autonomous vehicles. It will not be too long before production begins. It is just a matter of time before the technology is perfected.

If it goes well, you will probably have a fully autonomous vehicle by 2030 as safety issues are worked out. Nevertheless, this means automation needs to be tailored for specific manufacturers.

Instead of rigid programming, your autonomous systems for vehicles will include adaptation processes determined by AI and machine learning in an interconnected onboard network.

Additionally, sensors will automatically pass information to other road vehicles to avoid collisions. Essentially, automation systems will be adapted to let cars speak to each other.

When the technology is perfect and becomes standardized, the demand for process automation companies with advanced technology like AI and ML will increase substantially.

A Revolution in Process Automation

The car industry goes hand in hand with process automation and has remained relatively unchanged until recent years.

However, advancements in certain technologies are causing a revolution in process automation.

Some include 3D printing, AI and machine learning, and self-learning “cobots”.

However, the biggest challenge is adapting automation beyond the plant into self-driving cars. Nevertheless, it will not be too long before both industries change forever.

Main image by yarmoluk via Pixabay