Interview: Formic aims to change the way you integrate robotics and automation into your facility

Formic Technologies is a new type of company which, itself, is the result of the huge changes that are occurring in the robotics and automation market, what with all sorts of new robots and technologies emerging, none of which is cheap to buy, and creating an increasing amount of complexity when it comes to implementing them in an integrated system at, say, a factory.

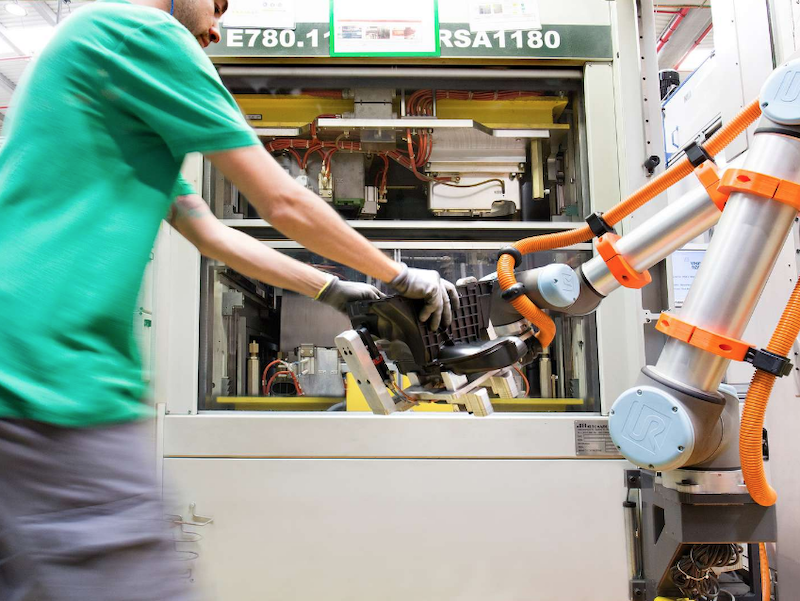

In simple terms, you can hire robots – for example, Universal Robots collaborative robots – and other automation technologies from Formic. But it’s more than that. You can also have Formic design the implementation, and handle the integration, for which the startup company has many established partners.

And possibly Formic’s unique selling point is its promise to link its income from its customers to those customers’ success with the automation systems Formic installs. In other words, it’s a kind of like a robotics-as-a-service company which you can pay as you go according to a sliding scale – or “Easy to start, easy to scale”, as Formic likes to put it.

The company claims to be able to offer 42 percent average savings on operational expenditure, 50 percent faster implementation, and $25,000 annual savings per system.

The types of tasks it has expertise in include machine tending, material handling, welding, and inspection. And the industries it works in include metal forming, fabrication and machining, consumer goods manufacturing, food and beverage, and logistics.

Robotics and Automation News spoke to Formic’s CEO and co-founder, Saman Farid, as well as Malcolm Kerr, the company’s business operations and strategy lead and asked them for more insight into Formic Technologies. (Questions asked at joint interview conducted by Abdul Montaqim.)

Abdul Montaqim: Tell us about your jobs at Formic Technologies.

Saman Farid: My job responsibilities are everything from janitor to fundraising to managing the strategy and hiring the team. We’re building this company so really I wear a lot of hats.

But I’m very excited by this kind of business that we’re building. I think our mission is to remove drudgery from the world of human labor and I think robotics really is the key that will unlock a new wave of productivity in global industry, and that’s really what we’re dedicated to doing.

Malcolm Kerr: I’m the business operations and strategy lead at Formic. Right now, that means overseeing all top of the funnel activities. That includes marketing, it also includes sales development, and I also do a lot of work around sales process in general, our go to market strategy and planning.

AM: Saman, as far as I understand, Formic is a new company that enables businesses to hire robots. Is that right? Can you explain a bit more?

SF: Sure. So we’re a combination between a robotics company and a financing company. Let me start with the problem we identified in the market.

Most users of robotics in manufacturing typically are only given the option to automate in a very complex way. So they would have to either buy some set of equipment and then hire an integrator to do some engineering and installation for them.

They would have to come up with capital. And then once they have that robot, they’re on their own for ongoing service and maintenance and all that.

What we realized is that most factory owners don’t want to become robotics experts. They want to focus on what they’re good at, which is owning and managing a factory.

So what we figured and what we started thinking about is, “How can we create a solution that solves 100 percent of the problem for them?”

Not 60 or 80 percent. What 100 percent of the problem means to us is everything – right down to the nuts and bolts. So when we walk in the door, they literally point at the processes that they want to automate, and we do everything else from that point onwards.

We know whether that means hard automation or if it means robotics or it means vision systems. We are responsible for all of those things.

We are also responsible for paying for it. We’re responsible for getting it up and running, and once it’s up and running, we’re responsible for maintaining it and servicing it.

Our customers are only looking for outcomes, and that’s all we provide. We make a commitment to them to move, let’s say, 10 boxes per minute from one place to another – that’s what we’re going to be measured by.

Whatever it takes to make that happen is what we will do. So, really, we want to create this new way to think about what call “full service automation”.

Our goal is to really make it extremely easy for manufacturers to adopt robotics automation.

AM: Typically, integrators are the ones who get the technology and hardware and all that on behalf of manufacturers and implement this system. How do you differ from integrators? What differentiates you from typical integrators?

SF: So, an integrator is typically like an engineering services firm. What they do is everything from programming the robot to installing the robot, and interfacing with equipment nearby.

So, for example, if you need to integrate with a CNC machine or a mill or whatever, it might be the case that you would hire an integrator.

The way they typically work is they charge you an hourly rate for their engineering fee, based on however many hours it takes to do the integration work – that’s what they charge you for.

But once they’re done, they’re not on the hook for for outcomes, so whether they did a good job or a poor job of integrating that robot, you are still responsible for paying them for every hour that their engineers spent doing the design and and installation.

The reason that that often becomes a problem is not because integrators are malicious – we love integrators and we work with many, many integrators ourselves – but integrators are typically optimizing for a different set of things.

They’re mostly optimizing for how to keep their engineers busy, how to sell more equipment, and how to continue to dominate the kind of region they’re in.

What we’ve found is that those incentives are a little bit different from what manufacturers need, not to mention that there is also the kind of financing aspect of it, where integrators need to pay upfront for all this equipment and they get the customers do that. And the customers are out of pocket by hundreds of thousands of dollars before they even know something is going to work.

So with our model, it’s a little bit different in the sense that we don’t charge the customers anything until the system is up and running. Once the system is up and running, we only charge for performance, so if the system works for three hours, then we charge for three hours of work.

If the robot is underperforming or it goes down for some reason, then we’re not getting paid. So we’re really putting our money where our mouth is and aligning our incentives with our customers.

But in order to do that, we have our own engineering team and we also work with a lot of integrators. The way that we work with them is typically quite different from the way that a typical manufacturing customer might work with them.

AM: Are you potentially competing with integrators and taking away business from them?

SF: I don’t think so. I think we we bring a lot of business to integrators and we hope to bring them much more in future.

Our business model makes it much easier for customers to adopt automation, so we think that with this kind of massive adoption that’s going to happen – of robotics and automation in factories – the number of robots that are going to be deployed on a monthly or yearly basis is going to go up drastically.

Our own engineering team can only handle some of the initial portions of that. We might do the design, but then we’ll hire integrators to do the installation or something like that. We have a lot of projects where we bring business to integrators.

And I didn’t talk much about the technology that we’re building, but we’ve built a lot of technology tools that also make it much easier and much faster for integrators to do their work.

One example of that is, in a traditional robotics application, an integrator would need to go into the site and spend dozens of hours measuring the customer’s facility and figuring out where the robot would go and what space is available to it.

Then they would go back and simulate the facility or they would just bring a robot and put it in place and then see if it works or not.

For us, we have actually developed a 3D laser scanning solution that we bring into the factory and in about two or three minutes we have a full 3D scan of that facility. Then, we have our team do a simulation of the robot in that 3D environment to verify that the robot will work, will fit into the space, that we’ll hit the cycle rates that we need to hit.

And we’ll create the design of the robot work cell in a very short amount of time – usually a matter of a day or two days.

Once we have that, it makes the integrators job much easier because there’s a lot less guesswork involved now about whether or not it’s possible to get the system up and running and where it will fit and what things like that.

Instead of that, with our solution, it becomes kind of deterministic and they just follow our designs and they build to our design. That’s one example. There’s many more like that.

We have technology tools that we’ve built that make it much faster and easier to deploy robotics and automation systems.

Another one that we’ve built is a fleet management and maintenance tool that monitors the status of all of the robots in realtime. It allows the users to switch between different robot programs very easily as well as um allows users to check for anomalies and temperatures or vibration or things like that.

These are typically indications that the robot needs maintenance. So we monitor and manage this whole fleet and proactively come in and do repairs as needed rather than go back to the traditional model where a robot might sit on the floor until one day it goes down and then everybody’s scrambling to find spare parts and get it back up and running or else the whole manufacturing line is down.

So those are the types of things that we we have built to make it easier for them.

AM: How much does your service cost to your customers? How much do you charge them, or how?

Malcolm Kerr: So we have a few levers to determine what the actual hourly rate will be. The first one is: what is the cost of the system going to be both in terms of the hard equipment cost as well as the engineering hours cost?

So that’s one factor that we take into account and calculate that into an hourly rate; the second question is, how many hours per day will that system be running; and then the third piece is the duration of the contract, so the longer people commit to working with Formic, the lower we can bring that hourly rate.

We’ve seen rates as low as $8 an hour, which we’re pretty proud of to be able to offer.

Our rates also get cheaper based on tiered usage, so it’s really not a single hourly rate, it’s actually more of a pricing scale, so we’ll say, “Hey, you use it this many hours per week, it’s this price, but if you use it more than that, then it gets even cheaper”.

So you can think of it almost like the opposite of overtime, but yeah it could be as low as $8 dollars an hour.

We’re seeing that, on average, that hourly rate is about 42 percent less than what people are paying today in manual labor costs and so we’re pretty confident that we can hit numbers that are very attractive to manufacturers.

AM: In your experience, has it been difficult to implement some systems for some customers? So you require several iterations to get it right? Or is the installation always flawless and smooth for every client?

MK: In a perfect world, every deployment is just flawless and absolutely perfect. But obviously, the reality is that sometimes changes do arise.

I think one really great thing about working with Formic is that we are just as incentivized to keep that equipment running as the manufacturer is. So, oftentimes, we will come in and do additional work, making sure that that system is running at no additional cost.

If there is some more significant kind of repurposing of equipment that needs to happen, sometimes what we’ll do is we’ll take the cost of that and amortize it across the rest of the contract people have with us, so the hourly rate might go up a tiny little bit, but nobody is absorbing that capex expense.

So that’s how we account for variations, but more often than not, we’ll just come in and make those adjustments as needed because we are incentivized to keep that equipment running – and that’s different from the way the industry works today.

We are totally aligned with the manufacturer.

AM: And do you get a lot of call for flexibility? I mean, I’ve heard that manufacturers often have to change their processes and setups. Has there been much unpredictability in your experience?

MK: That’s a good question. Typically, when something like that does arise, it’s something that we did not kind of anticipate at the outset. Most of the time, the applications that we’re focused on are ones that are really core to that manufacturer’s business that won’t change for a really long time.

But, inevitably, sometimes things do pop up. It’s like, “Oh, we want to repurpose that machine to work on a different part or work on a different machine”.

The way we handle that is similar to the way we were talking about variations earlier. A lot of times, we are happy to come in and make those adjustments because we want to keep that robot running as many hours as it can, so in that sense we are almost more of like a managed service, and all of that is baked into that hourly rate.

But if it’s the situation where that robot is being repurposed every two months in a really significant way, that’s something that we would probably amortize over the duration of the rest of the contract.

AM: And finally, do you think your business model can help the US and the industrialized nations more competitive against emerging economies in the manufacturing sector?

MK: We certainly believe that automation is going to be absolutely core to that. And not just automation in the way that we know it today, with a lot of kind of traditional industrial collaborative robots, but also in terms of technologies that have not really hit the market yet in a mainstream way.

I think one thing that’s really exciting that we think and talk about all the time is the idea of bridging the gap between all these really new innovative robotics companies that might be based in Silicon Valley and these companies – these small to mid-sized manufacturers – that maybe have been in business for a really, really long time but don’t have heavy experience with industrial automation.

If Formic could be the bridge that brings those two groups together, I think that would be really, really powerful for American manufacturing because we have a rich history and a deep set of experiences in the manufacturing sector.

We also have some of the most innovative companies on the planet that are constantly developing new and exciting technologies and I see that, right now, there’s not a really elegant way for those two groups to find each other and for advanced technology to find its way to the people that need it the most – the facilities that need advanced technology the most, and could benefit from from it the most.

I think a business model like Formic, where we’re saying, “We’re delivering outcomes, don’t worry about what technology it is – we are holding ourselves accountable to delivering this outcome”.

We could be using robots and technology from a traditional original equipment manufacturer that’s been around for a long time and you recognize the brand, or if we’re using a company that just raised its Series C and it’s based out of Silicon Valley and it has this new really cool exciting piece of technology.

We could do either. The outcome is still going to be the same.

What I think is really powerful and cool about Formic is our ability to realign the industry and have these people find each other and make it a much more conducive business model.

So I think it’s absolutely automation, but I don’t think it’s necessarily just automation in the way that we’re familiar with it today.

I think it’s also using the best of what our country has to offer and bringing people together so that we can reshore and continue the manufacturing resurgence in the United States.

I think that’s going to be absolutely pivotal.