Robot-ready conveying optimizes pick-and-place

By Ken Tinnell, vice president, general manager, Shuttleworth, a division of ProMach

From a machine builder’s point of view, robots can solve many processing and packaging line problems, but the chosen material handling systems supplying the line can reduce the robot’s performance. Smart Robot-Ready conveying solutions, such as Slip-Torque roller technology, DASH Dynamic Accumulation, SmartFeed, and flexible product control devices, engineered by Shuttleworth, enable precision robotic pick-and-place, maximizing system uptime and virtually eliminating product damage.

Flexibility, speed and accuracy make robotic technology ideal for pick-and-place applications in a wide range of industries. Tremendous gains in productivity are realized through the application of pick-and-place robotic technology. These robots also eliminate the risk of fatigue and injury that human labor is subjected to in these types of applications.

Robotic pick-and-place systems are low maintenance, flexible and reconfigurable, and especially beneficial in manufacturing and packaging applications when dealing with sterile, hazardous and potentially injury-causing materials.

Much of the effort of pick-and-place robotics is involved with engineering the end of arm tooling (EOAT) used to pick up items. A crucial aspect of robotic technology, EOAT refers to the equipment that interacts with parts and components at the end of a robotic arm.

Designing the correct EOAT is critical to establish precision product placement and handling, and successful pick rates, while minimizing product damage.

To ensure the success of the robot and the EOAT, it is crucial that proper decisions are made to feed the robotic solution, with an equal measure of precision, design and detail.

Products must be metered, presented and queued correctly in order to be picked by the robot. Also at play is a system of sensors and signals that tell the robot when and where a product is in position to be picked, and how many and how fast it may process.

And if a product has been missed and left behind, what to do or not do. Vision systems permit random picking and arrangement of products as needed.

Systems Integration of Pick-and-Place Robots

Utilizing articulating-arm robots, delta-style high-speed robots, and 4-axis SCARA (Selective Compliance Articulated Robot Arm) robots, a wide range of applications are possible for pick-and-place, sorting and end-of-line material handling.

High-speed pick-and-place robots, like the FANUC M Series delta-style robot, or the FANUC SR Series SCARA robots are perfectly suited for picking products and placing them into primary or secondary packaging with excellent repeatability performance and high-level accuracy.

When a robot is received from the manufacturer it must be programmed for the specific task. The level of flexibility and versatility required to handle the specific pick-and-place functions for end-of-line movement of products still needs to be programmed into the robot controller.

Maximizing the capabilities of robotic systems depends upon: 1) Programming the robot to perform the specific functions needed; and 2) How smoothly the robot is integrated into a singular, optimized manufacturing or packaging line.

As a standard practice, a turnkey integration encompasses examination of the efficiency of every system on the line and how that affects production rates.

These assessments may lead to built-in accumulation lanes to ensure the line keeps moving during short periods of downtime, or product groupings that reduce the need for frequent or unneeded movements by the robotic equipment, which take away from cycle time. All of these steps (and more) are taken to maximize and ensure high Overall Equipment Effectiveness (OEE).

The systems integration is where the real skill in robotics pick-and-place automation comes into play. This, in conjunction with the engineering of EOAT and vision placement systems, is where these pick-and-place robots are adapted to effectively manipulate multiple- and odd-product sizes, and randomly-oriented pieces.

But there is one more critical component to the systems integration that is frequently under-realized, yet vital to the successful performance of the entire robotic line. That is choosing the right conveyors, and their associated sensors and devices.

Conveyors for Robotic Pick-and-Place

Realizing the full potential benefit of robotic pick-and-place technology requires a material handling system that can match the speed and precision of the robot, to keep work flowing and prevent problems from occurring.

A conveying system engineered for integration within a robotic pick-and-place process is the best way to assure that the full potential of the robotic system will be realized.

Optimized design of the conveyors, and picking from them, reduces robot arm travel distance between pick-and-place locations. A few additional inches of travel by a robot running, for example, four-second cycles at 90 percent utilization, 24 hours x 6 days per week, adds considerable unnecessary additional motion to the robot’s gears, electric motors and drives.

But equally important is the robot’s ability to locate and pick items or products from the conveyor. Robots have to control and coordinate three independent speeds simultaneously:

- the robot arm velocity;

- the EOAT grasping speed; and

- the conveyor speed. It is the variable speed of the conveyor, and the relatively unpredictable exact position of products on the conveyor, that poses the biggest problem for systems integrators.

To pick up objects from a moving conveyor, the robot must be able to reliably locate them. This requires a sensor to detect when an object arrives at a position in front of the robot.

The robot also may need to track the objects as the conveyor moves. The most common sensors are vision sensors (2D or 3D cameras), and part-detection sensors (light beams, magnetic sensors, and inductive sensors).

Fixtures are an alternative to using vision sensors. These static mechanical parts which are fixed to the conveyor to move the objects into position are a more reliable way to order the objects on the conveyor without using sensors.

Objects are funneled into a static queue, allowing the robot to pick them up without using sensors. They make programming simpler, but they increase the complexity of the mechanical design.

Adding to the picking positioning challenge on moving robotic conveyors, which are typically belt conveyors, other factors contribute to making picking less reliable. These include:

- a) belt wear and slippage;

- b) worn and broken belt edges;

- c) the belt strained and pulled to one side;

- d) damage to the belt caused by abrasives, acids, chemicals, heat, mildew and oil; and e) insufficient traction between the belt and pulley.

Smarter Technology for Robotic Conveying

Three technology developments, combined called Robot-Ready, have directly contributed to improving product movement and positioning for high-throughput conveying with robotics: a) Slip-Torque roller technology; b) DASH Dynamic Accumulation; and c) SmartFeed.

These were developed by Shuttleworth, a leading designer, manufacturer and integrator of conveyor solutions to solve material handling challenges. These conveyor technologies provide precision capabilities to accumulate, flip, stack, rotate, push, divert, combine and index products throughout the robotic pick-and-place process.

Slip-Torque Roller Technology

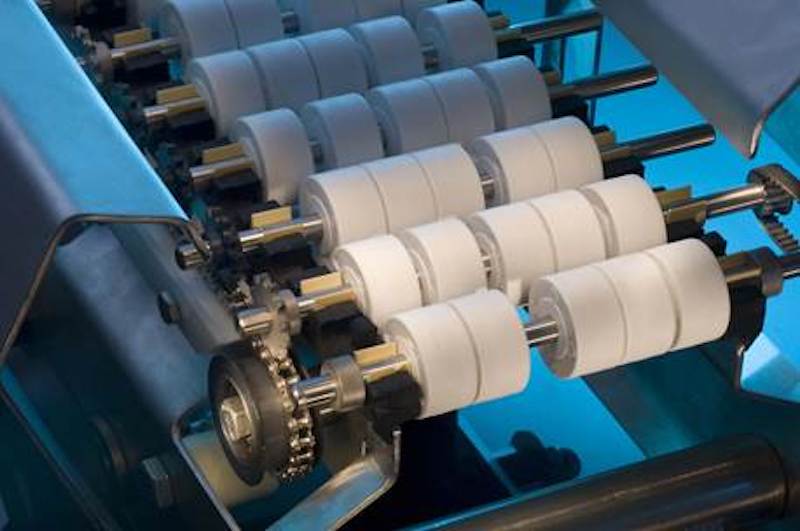

Slip-Torque roller technology utilizes individually-powered, stationary, rotating roller shafts covered with loose, segmented rollers, which become the conveyor surface.

When the product stops on the surface of the conveyor the segmented rollers beneath also stop, generating low back-pressure accumulation, minimizing product damage.

It is the weight of the products being conveyed, combined with the coefficient of friction between the shafts and the inside diameter of the rollers, that provides the driving force. As the weight of the conveyed product increases there is a corresponding increase in the driving force supplied.

Slip-Torque’s low line-pressure provided throughout the conveyor, and its continuous-motion Dynamic Accumulation allows for precise placement of products on the conveyor while it continues to take products from an upstream line for a period of time, where conventional conveyors would have stopped well before.

A low back-pressure accumulation buffer absorbs irregularities in the production flow and provides a smooth, even flow on the line.

Slip-Torque roller technology minimizes product contact, while steering products into precise location for robotic picking.

Conveyors with Slip-Torque have the ability to modulate the speed of different sections of the conveyor via a centrally-controlled PLC and HMI. As products are moving down the line, the rollers at the back end of the conveyor can be moving faster than the rollers before them.

The products can be moving at variable speeds on different sections of the conveyor as dictated by throughput requirements. This controls the product spacing on the conveyor, keeping the products separated and equally spaced from each other to minimize product contact.

The Slip-Torque surface can also be used to minimize product contact while steering products into desired locations, such as employing rollers with herringbone patterns to orient the products without the use of guardrails, or setting up a series of sequentially smaller roller heights to direct products into the center of the conveyor for singulation without touching any other conveyor parts.

Slip-fit rollers with tapered corners can be used to maintain product orientation, gently and safely, as products are transported through 45-degree and 90-degree conveyor turns.

Because of the unique features of Slip-Torque rollers, the conveyor system is a safe environment for workers that work near and interact with the products being carried on the conveyor system.

The roller contact surface is designed to stop immediately if a hand is placed on it, thus maintaining a safer working environment. The Slip-Torque surface is also ideal for robotic picking of accumulated product. The low line pressure from the conveyor surface prevents damage during the picking process to the accumulated product, robot arm and EOAT.

DASH Dynamic Accumulation

DASH Dynamic Accumulation absorbs surge or gap irregularities in the production flow, and evens the rate of product discharge to provide a smooth, even flow on the robotics induction line. It uses a mechanism that divides the products out into multiple lanes and accumulates them on a low line-pressure conveyor.

This can be used for managing the product flow to better match robotic inflow. It can also be used when a robotic cell downstream goes off line, to continue to accept products upstream for a time. Then, when the downstream work cells come back up the accumulated products can be released downstream.

The system allows the same conveyor to be split into multiple, independently-operating lanes, if desired, dynamically. For example, the middle lane can accumulate, while at the same time the right lane and the left lane can both convey.

Each lane acts independently, if needed, but is powered by only one common motor, which also reduces energy usage. Servo-controlled guides provide efficient lane changing of incoming products, eliminating product backlog at the point of entry.

DASH combines the benefit of gentle product handling, efficient line balancing and accumulation into a compact footprint design using low-back-pressure and low-friction operation in applications with high-speed robotics capabilities of up to 600 ppm.

SmartFeed

To achieve a much more consistent level of infeed registration with robotic packaging machinery, Shuttleworth developed a series of three automatic infeeds, called SmartFeed. Working in combination with Slip-Torque conveyors, SmartFeed links machine infeed to upstream product flow. It is designed to accumulate and synchronize the release of products for metering or machine feeding without stopping the production flow.

SmartFeed operates by timing the release of products, or a group of products into a flighted infeed with a pneumatic/electric gate, or a servo-controlled variable-speed surface. With a speed-up zone near the discharge end of SmartFeed, one product, or a group of products, at a time is placed onto the infeed of the machine. The spacing is very precise, with a tolerance of 0.25 inch to 0.5 inch.

SmartFeed is in synchronization with the machine using encoder feedback from it. A sensor identifies each product’s location, and then the conveyor will either accelerate or decelerate the product to place it into position on the flighted infeed of the machine. The robot then can grip the product, or group of products, for induction into the case packer or other downstream packaging machinery.

The system operates in four speed-registration zones to manage the metering of products:

- The first zone accepts the product from upstream manufacturing or upstream packaging systems, or a staging point, then conveys it downstream;

- The second zone closes the gaps between products, running them back-to-back;

- The third zone increases the spacing between the products equal to the pitch flight on the packaging machine;

- The fourth zone positions each individual product into the gaps between the flights.

The downstream machinery and SmartFeed are always talking to each other, and reacting to whatever products are moving through the line. When there is a delay with an item, SmartFeed tells the machine that no item is in position, and to slow down or stop.

When the next item is in position, SmartFeed tells the machine to start, providing there is accurate indexing of the product. System controls installed upstream regulate the speed of the line throughout directed by input from SmartFeed. In this way, SmartFeed creates an integrated system monitoring the flow of products up to and into the robotic cell.

Several versions of SmartFeed can be integrated for supporting robotic packaging of products:

- a) Gated SmartFeed and High-Speed Gated SmartFeed – use a product stop to synchronize the release of products to the flighted infeed of the machine. The combination of the low-pressure queue area, speed change and the product stop makes for jam-free operation. Gated infeeds operate at rates of 20 to 80 products per minute. The high-speed infeed can reach rates of 120 products per minute.

- b) Multi-Packer SmartFeed – is designed to release a pattern of multiple products in time with a flighted or belted infeed. A product stop, combined with an adjustable overhead brake, controls the number of products released.

- c) Servo-SmartFeed – combines buffering and indexing into a single-source solution for infeed of products without the use of devices. This system monitors production flow and delivers this information to the robotic case packer, or other machinery for speed modulation. Servo-SmartFeed automatically synchronizes to the robotic machine, so that the products are precisely and consistently placed on the infeed of the machine, and ready for picking by the robot.

Product Control Devices

Many conveyors used as robotic infeeds enable the adaption of product control devices, such as product stops, pushers and clamps that can be used to modify the flow of conveyed products.

Most conveyors bring these devices in from the side or even over the top, such as would be found on belt conveyors, plastic link conveyors or table-top chain conveyors.

Side-mounted devices are limited in their flexibility to control product flow because of their side-only mounting locations, and top-mounted devices are considered even less desirable by manufacturers because of safety and product contamination concerns.

Conveyors equipped with Slip-Torque roller technology function differently with regard to product control devices. utilize space between rollers to allow these devices to be mounted below the surface, reaching up.

While side- or top-mounted devices are still possible, Slip Torque conveyors offer the option to between the rollers to effect more precise and flexible product motion control, with minimal interference with the line flow or the robot. This provides another level of control, flexibility and the ability to make a precise pick.

Product control devices can be more specifically located on conveyors equipped with Slip-Torque compared to conventional systems, and bring a much higher level of positioning accuracy with more positive product handling.

Here are some examples of the product control devices that are applicable to the conveying of products for robotic infeed:

- a) Blade stops and brakes that enable on-demand stops and starts of product flow;

- b) Lift-and-transfer, lift-and-rotate, side transfer and turntable devices are used to provide a smooth and accurate product transfer at a 90-degree angle to the original transport direction, or to change the orientation of products on the conveyor;

- c) Product positioners accurately position or rotate products for a particular process, such as for scanning bar codes in labeling;

- d) Pushers used to that push single products or a group of products perpendicular from one conveyor traffic lane to another traveling in the same or the opposite direction. Used for pushing products into or out of ovens and freezers, and operator workstations or off of the conveyor system completely;

- e) Single-row combiners efficiently merge products in multiple lanes into one single row;

- f) High-speed telescoping, and custom product diverters and laners can gently direct the flow of products to a particular lane for efficient buffering or line balancing;

- h) Diverters that move products from one line to another to keep production flowing, such as when one line may become stopped downstream on a multi-line production system;

- i) Chicaning to take random, misaligned or grouped products, and spread them into a single file line;

- j) Laners that put the products onto multiple lanes, or to spread products out before robotic picking;

- k) Vision used to inspect products for alignment or position, and to fix orientation before going into a robotic pick station. It can identify if a product is out of position, so it can be taken out of the line with a high-speed reject mechanism.

Robot-Ready, the Missing Link

Maximizing the capabilities of robotic pick-and-place systems for manufacturing and packaging depends upon how smoothly the disparate functions are integrated into a singular, optimized line. Robotic infeed conveyors, like Robot-Ready, provide the missing link to achieve this high performance.