Beginner’s Guide to Generative Design for Engineers

In the last couple of years, there’s been a big buzz in the engineering world about “generative design”. This methodology holds a big promise to revolutionize the way the world creates products.

It mainly draws on artificial intelligence and cloud computing. Over the years, generative design has served as a means of creating the highest quality designs.

Defining generative design

What does this term mean, really? The New Equipment Digest defines it as: “Generative design enables engineers to create thousands of design options by simply defining their design problem – inputting basic parameters such as height, weight it must support, strength, and material options.”

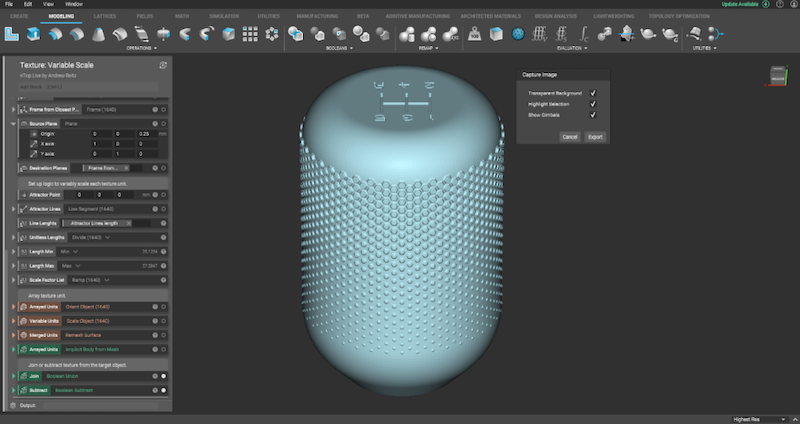

Generative design is a broad term, a technology that uses computational approaches to assist the world of engineering. Engineers nowadays use software to design products by evaluating geometry and utilizing logical operations.

When an engineer works on generative design, they create and optimize 3D models by using computer software. The user sets up their preferences for the design, including details related to the manufacturing and constraints, and the software automatically works to meet the requirements.

Smart software does not eliminate the need for actual human work. Designers and engineers still need to consider the physical constraints, material availability, weight limits, and more. In other words, this technology mixes and matches the capabilities of designers and engineering with those of smart digital tools – all to provide an optimal solution.

Why is generative design important

In a very short time, generative design can create hundreds of quality design options based on the engineer’s requirements. Since it taps the cloud system for resources, this technology provides fast and accurate designs. The capabilities can vary greatly from one software solution to another. One of the best choices among engineers nowadays is nTopology’s generative design software, a tool that gives users complete control of the design workflows.

Thanks to this tool, engineers can speed up the cycle of development, create better results, all by utilizing advanced technologies for manufacturing. Here are the three main reasons why this is important:

- Autonomous designing with AI assistance. By definition, this technology enables engineers to use AI to create autonomous designs.

- Rapid results. An overall benefit of generative design is that it brings quality products to the market in a very short, record time.

- Increased reliability. The software carries out stress analyses to determine if the product is reliable, durable, and of high quality. This eliminates unnecessary costs later on and ensures that the product will work.

These things mean that there’s truth to the current buzz in the engineering world. In this article, you’ll learn about the best ways to apply this technology to your engineering.

How to apply generative design to engineering projects

Let’s start with a couple of actionable tips:

- Don’t overdo it. Even though generative design can be very useful for your projects, it won’t create the product with the push of a button. You still need to invest time and effort into this, so start small.

- Carefully codify design requirements. Remember that generative design works well only if you provide it with the right requirements. Be as detailed as it can, and in a language that the system understands.

- Understand that this is a work in progress. Even when the generative system comes up with a product, this isn’t the final step. You will still have to continue to progress and implement that design until it is fully ready.

Now that we’ve shared these useful tricks, it’s time to delve deeper into them. To better understand how to use generative systems, you need to know the following.

Design requirements that you should use

Engineers have the ability to examine the context of the design and decide on how to proceed. Generative technology, on the other hand, does not have the human factor. This means that it has to be told unambiguously what to do.

So, engineers have to do some modeling for this to work.

For starters, you need to think about space requirements for the design. Surely, some of these will be pretty straightforward, but others won’t. Space limitations are simpler – you just need to tell the systems which are the areas where they can or cannot put geometry. While doing so, you must also provide details on what type of geometry should be in the design.

This is a critical part of the design requirements, but far from the only thing to codify.

Other requirements can be a bit more complex – and depend greatly on the design in question. At this point, it is the job of the engineer to prioritize the most important tasks. If you use generative systems, overspending resources or loading all sorts of requirements into it will not end up well.

So, what should you be considering here?

Let’s say that you’ve decided that your design should be with minimal stress, so you tell the system exactly that. But, you might forget about maximizing stiffness, minimal mass, or fail to set requirements about the temperature differential. Unless you prioritize the key requirements, the system won’t be able to come up with the product you imagine.

How to use generative systems

Good engineering projects require a quality design study. If you decide to go for generative design studies, keep in mind that this will use money, time, and a variety of computing resources to provide you with the results. It’s very important to enter the right information to perform accurate generative analysis.

Here are a few tips you should know of:

- This approach will generate hundreds, if not thousands of solutions for you. If you don’t need as many solutions, you might want to reconsider the idea.

- Unless you are able to deliver the design solutions that are generated, or don’t have the time to do it, eliminate that option.

- Don’t forget about the modeling fundamentals. Even generative design spaces models need these. Design the design spaces properly based on the design that you are working on.

- You have biases that can influence the process. To create optimal products, you need to set up the generative study without bias. This means that you cannot discount any combinations that you believe won’t work, or omit manufacturing processes that your company doesn’t have expertise in.

- Consider different types of materials. Generative technology can help you solve problems by picking the right kind of materials. Still, this technology doesn’t understand all material characteristics. It’s your job to consider different types because the generative systems might not have all the necessary information to make the right decision.

Generative technology only takes you a few steps further

Even after you perform an excellent generative study and the system comes up with a great design based on your data, you still need to tweak parts of it. This technology has been amazing in the engineering world, but its creation is not final without human contribution.

The design is a work in process. Once you have the product ready, engage once to ensure that it is manufacturable and make it ready for production.

All this means that you need to figure out the best way to turn your generative product into a traditional CAD boundary representation form.

Understand the difference between this type of technology and topology optimization

These two terms are used interchangeably, but there are significant differences between them. Generative design converges on a variety of solutions at the same time to come up with the optimal set based on engineering and functional requirements. Topology optimization, on the other hand, evolves a single solution based on constraints, functional objectives, and loads.

Generative design in the engineering world today

Generative design is very popular in the engineering world today. It is used by novice engineers, those at the entry level to learn better and achieve results faster. This technology allows them to produce quality generative models fast.

However, it’s not only used by entry-level professionals.

Generative design is used by engineers of all levels, helping them test the conditions and curate the parameters, as well as come up with quality designs fast.

This powerful technology is helping companies deliver something well-planned, organized, and optimized based on specific requirements. One example of it is the development process of Volvo. When they needed to use a fully variable electric motor in the place of a belt-driven fan clutch, they needed a new mount. Their first design was not at all simple – it required a 3-piece sub-assembly. So, they used generative design to turn this into a 1-piece assembly, therefore creating a more affordable, more efficient solution for users.

Thanks to generative technology, the company created the perfect design space based on available engine volume, one that includes all the neighboring components and mounting points. In their project, they also included the motor, applied constraints and loads, as well as selected mass targets. The aim was 1 kg and the result was much lighter than the original product.

There have been many examples where the automotive industry designers utilize this technology to improve weak design areas, reduce the weights of components, and decrease costs of production. But, that’s not the only area where generative design is used.

Similar to this, the sports equipment industry uses generative designs to minimize production costs and maximize product performance and quality. There’s also the aerospace industry where engineers assist airline manufactures in improving the plane components’ strength and reducing the weight. As a result, airlines can lower emissions, costs, and reduce fuel consumption.

It seems that this technology is here to stay and it offers more benefits to engineers every day. Hopefully, this guide provided you with useful information.

Main image source: Autodesk