Specifying a Linear Actuator: 3 Key Factors

By Japh Humphries, UK Sales & Commercial Manager, Matara UK

Linear motion systems are business critical across an extensive range of industries, from food processing plants, to semiconductor manufacturers and packaging producers to name but a few.

In fact, virtually anywhere that requires loads to be cost-effectively moved in a straight line, safely, securely and precisely.

These systems have improved automation whilst simultaneously lowering production costs, making them invaluable.

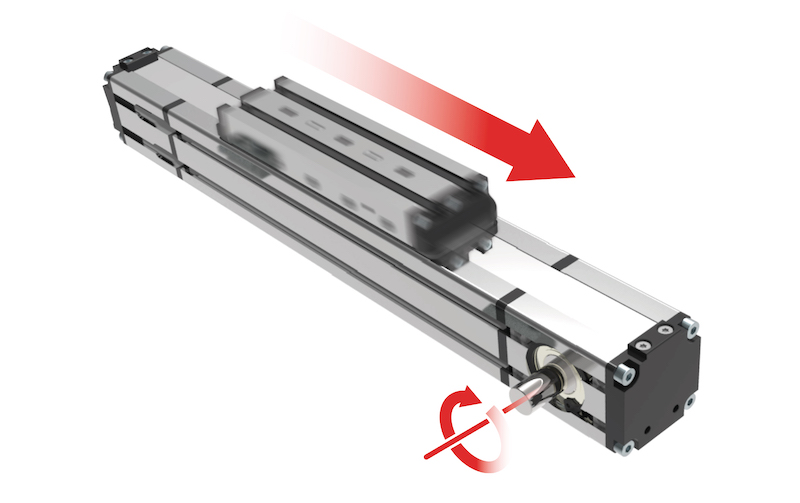

Linear actuators are at the heart of a linear motion system, combining linear guides and power-transmission components in a single unit.

Whilst machine builders can opt to design and produce these elements in-house, the majority opt for off the shelf, “ready-made” linear actuators as it reduces overall machine design and fabrication costs and, as they feature application-tested and optimised construction, are highly reliable, accurate and provide repeatability; all of which are core to production machine and automation systems.

Whilst it’s important to consider all components of a linear motion system separately and as a whole, choosing the right linear actuator – belt driven, ball screw driven or electric rod type actuator – is fundamental. There are a number of factors that should be taken into consideration, but three stand heads and shoulders above the rest and will ‘make or break’ a system.

Key Factor 1: Speed

The speed of the process at hand will impact the actuator’s longevity and efficiency.

A ball screw linear actuator will usually perform at around 0.35 to 1.5 m/s at stroke lengths under one metre, although higher speeds and longer lengths can be achieved by adding supports to the assembly.

However, this will only take you so far as a ball screw actuator may be susceptible to “screw whip” at high speeds, where the screw vibrates and bows as it turns. Over time this can negatively impact the performance of the actuator, leading to premature wear and shortening its lifespan.

Whilst there isn’t a universal cut off point at which a ball screw linear actuator is no longer an option – it’s very much dependent on a range of factors including the dimensions and material of the screw and the actuators’ use and environment – if you want to achieve higher speeds, up to 3 m/s, then a belt actuator should be considered.

Belt actuators perform better at higher velocities and also in applications that require a long stroke. Which brings us to our next key factor.

Key Factor 2: Stroke Length

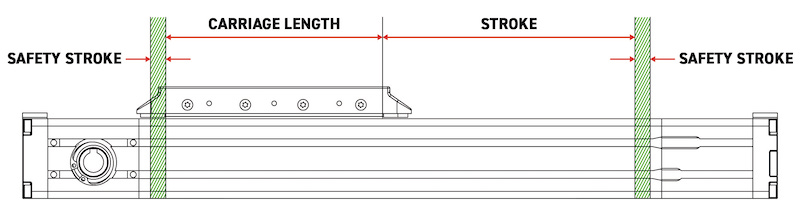

Stroke length refers to the distance the linear rail actuator is required to move a load in one direction.

Linear ball screw actuators are usually designed at around 1,000 mm stroke length, although smaller and larger lengths can be accommodated by, for example, using different diameter balls.

However, we would never recommend a ball screw actuator for stroke lengths over 54,000 mm. For longer stroke lengths, belt driven actuators are a better option. At Matara, we are able to manufacture linear actuators from 100 mm to 6,700 mm stroke lengths.

One of the most important considerations when looking at stroke length, and one that all too frequently gets overlooked, is the safety stroke.

The safety stroke is an allowance that provides room for the actuator to coast to a stop if an emergency stop of the system is necessary. This prevents the bearing table (and the load) from hitting the ends of the actuator, which can cause damage.

Even if emergency stops are rare in your particular process, it’s still good practice to factor in a safety stroke as linear actuators aren’t designed to constantly be run into a hard stop as this can cause wear and tear to the inner workings of the actuator over time.

To calculate the safety stroke, for belt driven actuators specify a distance equal to two turns of the motor on each end of the actuator (or four turns in total). For ball screw actuators, base it on twice the pitch of the ball screw. Other factors may have to be taken into consideration, but this calculation is a good starting point.

Key Factor 3: Load

Stroke length impacts on speed and vice versa, but load has a direct effect on both.

Anyone involved in an engineering capacity will appreciate the importance of load capacity on a structure and linear motion systems are no different in this respect. Miscalculate the load and at best there will be a loss of precision, but at worst you may be looking at catastrophic failure with damage to the actuator assembly and the product, and a potential serious health and safety risk.

Where linear motion systems differ from many other load capacity calculations is the need to base it on the dynamic load capacity. Unlike the static load, which is the load on the actuator when it is in a fixed position, a dynamic load is that which the actuator handles when in operation and in motion. In other words, how much work can the machine actually do; how much can be pushed or pulled.

You need to base the calculation on both the radial and axial load capacity, as well as the moment capacity of the support carriage. Position of the load in terms of its size (including any overhang) as well as the orientation in which the load is being moved should also be considered.

Ball screw driven actuators can generally move higher loads and are widely used on applications that require movement on a vertical axis, such as gantry robots. A belt actuator should mostly be avoided for vertical axis movement as it is at risk of the belt snapping due to tension.

However, belt driven actuators can be ‘beefed up’ to achieve higher dynamic load ratings by using linear rail and carriages as external guides. Linear rails have two parallel tracks that contain rollers to support a moving load, providing guidance and support for a load carried by an actuator between two points.

Linear rails are used in a whole range of applications and can carry loads that vary from extremely light electronic components, through to large loads weighing thousands of kilograms in heavy industry.

Ultimately, the choice of linear actuator will be impacted by all three factors and which factor takes priority for the machine being designed and the process for which it is intended. There will also be other factors to consider, including the direction in which your actuator is mounted, accuracy and repeatability, maintenance requirements and the operational environment. But without getting the big three right – speed, stroke length, load capacity – none of the others will matter.

Matara designs and manufactures a range of pneumatic and linear automation products, including linear rail actuators. Products are available from stock or can be custom built to order.

For more information, contact us:

https://www.matara.com/products/actuator-systems/linear-actuators/

sales@matarauk.co.uk

Telephone: +44 (0)1684 850000

About the author: Japh Humphries is the UK Sales & Commercial Manager at Matara UK Limited, based at Tewkesbury Business Park, England, United Kingdom.