Design brief: 3D printed casting of 3-foot long robot arm

By Alkaios Bournias Varotsis, product marketing manager, nTopology

3D printed sand casting molds and cores are changing the way high-performance, large metal parts are manufactured today.

Additive manufacturing is enabling modern foundries to produce complex metal parts in rapid lead times.

This article explains the benefits of coupling advanced design tools with 3D printed sand molds using, as an example, the redesign and manufacture of a 3-foot long robotic arm.

Sand casting and industrial 3D printing

Metal casting is a common and well-proven manufacturing method used to produce goods that we incorporate into our daily lives. 90 percent of all manufactured products and machinery today include components made using casting.

Watch this short video about the project. (For a longer video interview with nTopology’s vice-president at nTopology, Duann Scott, see below at the end of this article.)

The most popular metal casting process is sand casting; over 70 percent of all metal parts are manufactured using this production process.

The sand casting process begins by creating a sacrificial mold that consists of compacted sand mixed with a binder. The mold’s cavity is then filled with molten metal through a gating system before the mold is destroyed to release the cast part.

Sand casting dates back to the 1st century BC. Over the centuries, it has evolved into the industrial process we know. Yet, foundries today are further enabled by the advent of digital manufacturing and 3D printing technologies.

Sand casting using 3D printed molds and cores is emerging as a key industrial application of additive manufacturing. Until recently, design engineers and casting foundries used this hybrid manufacturing technology primarily for prototyping.

Today, more and more foundries in the US and overseas are adopting this manufacturing technology to augment their internal processes.

Benefits of sand casting with 3D printed molds and cores

Here are some of the ways that 3D printing can benefit a casting foundry:

- 3D printed sand casts and cores facilitate the creation of gating systems and risers that result in high-performance metal parts with fewer internal defects and up to 15 percent higher material strength.

- Additive manufacturing eliminates the need for hard tooling and casting patterns and the associated geometry restrictions. This benefit facilitates the production of high-performance, optimized parts with complex geometry.

- 3D printing and other digital manufacturing technologies help transform the image of the traditional foundry, attracting young talent and new workforce to the field.

Limitations of sand casting with 3D printed molds and cores

However, 3D printing is only a tool. The limitations of this new technology in regards to sand casting include:

- Part design should still follow the restrictions imposed by the casting process and the 3D sand printing systems. These design considerations include wall thickness, changes in part cross-section, and wall-to-wall thickness.

- The current availability of industrial sand 3D printers is limited, and the cost of manufacturing 3D printed molds are relatively high. For reference, sand 3D printing costs approximately $0.1 per cubic inch, while a traditional foundry usually charges between $10-20k for a mold.

- As with every new technology, access to knowledge and design expertise is still limited. Elusive best practices and design guidelines stop engineers and manufacturers from getting the most out of this new technology.

The following case study directly addresses the last point. By documenting the design method and practical considerations that went into each decision, we hope to make this technology more accessible to manufacturers, designers, and engineers.

Case study: Topology optimized robot arm

To demonstrate the benefits of sand casting with 3D printed molds and cores, the engineers of nTopology, Penn State University, Flow 3D, and Humtown joined forces to redesign a meter-long robotic arm. Together they created an end-to-end digital casting workflow – from part optimization to design for manufacturability and, finally, manufacturing.

The team combined cutting-edge design techniques, like topology optimization, with advanced casting features that can only be manufactured additively (including the sprue, gates, and risers). Using this method, the team managed to:

- Reduce the weight of the part by 40 percent

- Avoid common casting defects

- Directly 3D print the entire sand mold

- Manufacture the part in less than a week

Generating a lightweight robotic arm

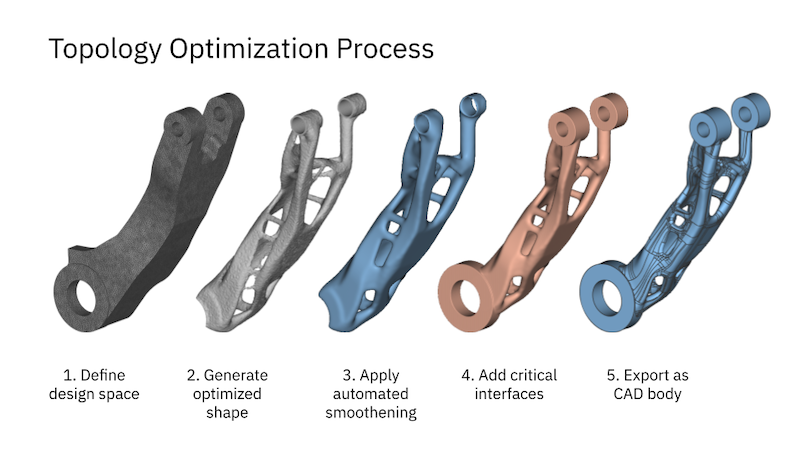

The first step in this project was to optimize the geometry of the robotic arm. Using topology optimization software, the team reduced the weight of the part by 40 percent — from 240 lbs down to 165 lbs — while still fulfilling the functional requirements of the defined loading conditions.

Topology optimization is a simulation-driven design technique used to maximize stiffness and minimize weight in aerospace and automotive engineering applications. The automated smoothening and reconstruction capabilities of nTopology enabled the team to make design changes quickly and with little effort.

Of course, the engineering team considered the manufacturability of the part during the design phase. The final metal part weighs 165 lbs (or approximately 75 kg) when cast in aluminum and has bounding box dimensions of 39” by 16” by 16” (or 1.0 m by 0.4 m by 0.4 m). The robotic arm’s size limited the options available to the team to produce this huge part.

Dr Ryan O’Hara, director of aerospace engineering at nTopology, says: “The only way to make a part this big and this complex is to leverage advanced manufacturing. Direct additive manufacturing techniques, such as SLM or EBM, were not an option due to the size of the part. For this reason, we decided to couple additive manufacturing with a sand casting mold.”

Following the traditional mold-making method (using a master pattern) would introduce several complications. Due to the complexity of the geometry, the design team would have to make many compromises, reducing the performance of the part.

Optimizing the design of the cast

To demonstrate the capabilities of the technology, the team decided to directly 3D print the entire mold. A more common production scenario would be to 3D print only parts of the mold, like the mold’s cores or other critical-for-quality systems.

This decision enables the team to optimize other critical features of the mold, like geometry and location of the sprues, gates, and risers. This process ensured the metal cast would have minimal internal porosity and high-performance material properties.

The mold was designed through a collaborative effort between Penn State University and Flow3D. The team took two main design requirements into account during this step:

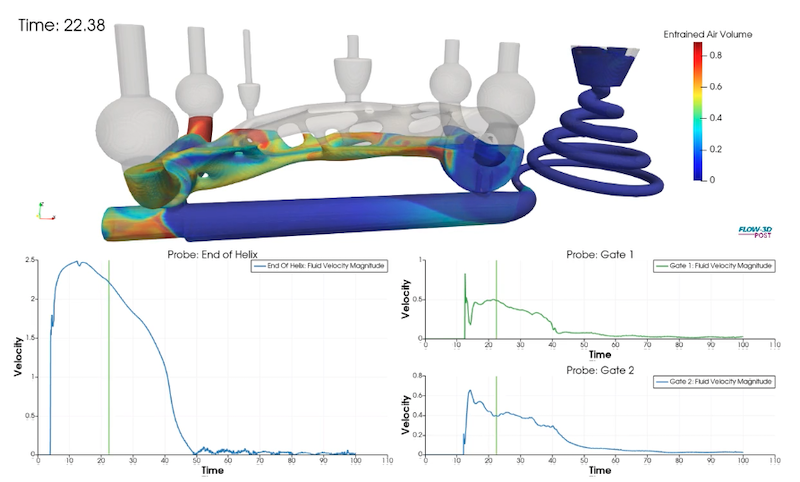

- The molten metal must fill the cavity as smoothly as possible. Research has shown that flow rates below 0.5 m/s are necessary to minimize turbulence and reduce the possibility of material defects due to oxide layer detachment and porosity.

- The risers must solidify after the part. Uneven solidification is another common cause of internal defects, shrinkage, cracking, and part deformation. For this reason, the sections that will be machined off the part after casting must solidify last.

To ensure that the material would fill the mold without introducing turbulence, the team reimagined the design of the gating system and the risers. Instead of a down sprue, they used a spiral helix probe. Instead of cylindrical risers, they opted for risers with a spherical or hemispherical shape.

This optimized sprue and riser geometry ensured that the flow speed of the molten metal is below the desired threshold and that the molten metal would solidify evenly. Moreover, these features could only be made using direct additive manufacturing technologies, as it is impossible to create such tooling using a traditional casting pattern-making process.

To determine the best part orientation and the optimal position of the runner, gates, and risers, the team ran multiple design iterations using casting simulation software. The goal of the simulations was to optimize riser performance, minimize porosity, and verify gate flow velocities. The simulation stage ensured that the part would be manufactured first-time-right and reduce the development time from months to weeks.

Dr Guha Manogharan, assistant professor, Penn State University, says: “In this project, we applied all the sand casting knowledge that we have developed in the lab. We were able to incorporate theoretically optimal sprue and riser designs that cannot be manufactured using traditional methods. That was very effective in reducing the overall defects and was further validated using simulations.”

The unique direct production capabilities of the 3D printing process enable the production of these advanced mold design methodologies. They are also proven to yield significant performance improvement. Research has shown that, compared to traditional methods, cast parts produced using this model have:

- 99 percent lower defects for a total of 0.02 percent internal non-metallic inclusions

- 8 to 15 percent higher strength when cast using the same materials

The improved performance of the as-casted materials makes this process most relevant for foundries that create high-performance or custom parts.

Streamlining the manufacturing process

The ability to quickly produce the desired complex shapes and structures necessary in sand was fundamental to the part’s manufacturing to meeting the project’s goals.

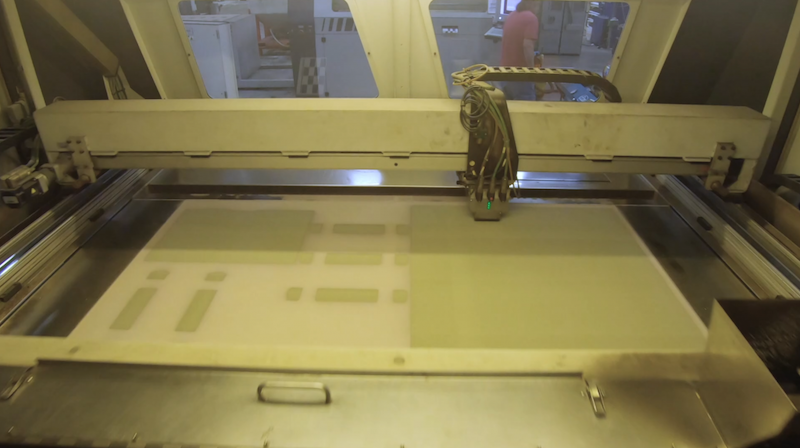

Humtown used one of their four ExOne SMax sand binder jetting 3D printing systems to the mold. Once the engineers of Humtown received the final mold design, they were able to print the mold in less than 24 hours. Due to their close partnership with Humtown, Trumbull Foundry was able to cast the mold within one day.

Humtown is one of the leading solution providers of 3D printed sand casts in the US. They have embraced new technologies and they now encourage other foundries to adopt new casting methods to create a lean and agile supply chain ecosystem.

Brandon Lamoncha, director of additive manufacturing, Humtown, says: “We need to start pushing casting to its limits. The biggest threat is staying the same – doing what we’ve always done. We need innovators who take advantage of new software to remove barriers in part and casting design. We also need foundries in the US to embrace new technologies to remain relevant on a global level.”

Key takeaways

3D printing technologies are changing the scenery of metal casting. 3D sand printing enables design and manufacturing engineers to:

- Produce optimized large parts with complex geometries

- Design casting molds that minimize internal material defects

- Build leaner and more agile manufacturing supply chains

About the author: Alkaios Bournias Varotsis is on a mission to empower engineers to take advantage of the new possibilities unlocked by advanced manufacturing processes, Alkaios is passionate about all things related to cutting-edge technologies. He has a background in engineering and a PhD in Additive manufacturing. Before joining nTopology as the Product Marketing Manager, Alkaios pursued his own entrepreneurial ventures and worked with pioneers in the space of digital manufacturing, including 3D Hubs.