Why you’re looking at AGV / AMR technology all wrong

How can a company looking to implement automation select the AGV/AMR that best suits them? How can automation integrators predict which manufacturers will help them hit the ground running and deploy on time and on budget?

When seeking technology solutions, buyers often look to research reports and industry pundits for guidance. Yet we claim that the current view provided in most reviews is misleading: It is missing a fundamental shift that is happening today in the AGV/AMR market.

That shift is the rise in the importance of agility, speed and customization as a leading success factor.

The changing face of industrial automation

In the last decade, industrial manufacturing and retail have seen a shift towards flexible business processes, personalization of products and agility.

Digital transformation, AI and IoT are enabling a shift from profitability through cost reduction to profitability by addressing customer demand for uniqueness and personalization, and through process innovation.

The global market for mobile robots is estimated at $10.7 billion in 2020, and expected to grow to $72.5 billion by 2030. Demand for automation is exploding and so are the options to choose from. STIQ have identified 231 vendors, but believe that number to actually be much higher.

There is also a demand to meet a growing number of highly specific use cases, in dynamic, non-sterile environments. AMRs are becoming complex systems, a combination of proprietary hardware, proprietary software and specialized components, that adhere to a growing number of standards.

So what’s wrong with the old approach to AMR technology?

The industrial automation environment has adapted to the new dynamics by developing sophisticated software technology and software development methodology and tools. The common view of the market, however, hasn’t caught up.

Many analysts and reporters still look at the market in a siloed way that is focused on form factors or a single high level functionality – mainly navigation technology. This view prevents stakeholders from grasping the true picture of the technology building blocks and market dynamics.

What’s worse, it keeps automation players from obtaining the cutting edge solutions they need.

Flexible development implies a high level architecture that allows flexibility and software development approach, methodology and tools that are more similar to other domains such as cloud-native, than the traditional vertically integrated AGV domain. To understand this change, let’s look at what’s under the hood of an AGV/AMR

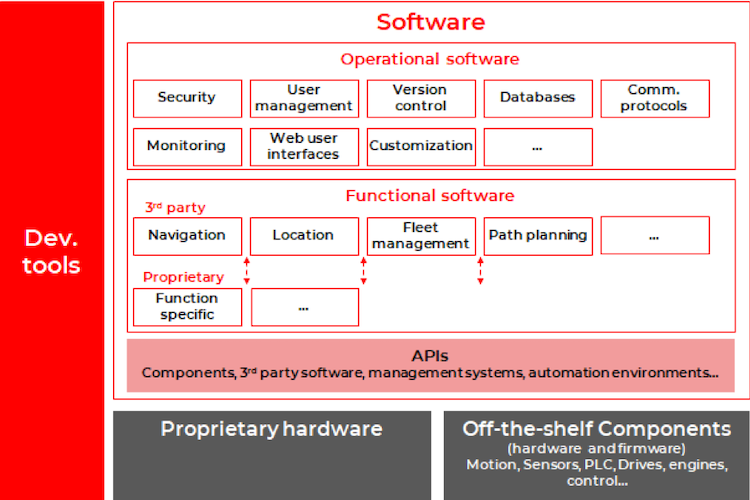

How are AGVs/AMRs built? A conceptual architecture

While in the past AGVs/AMRs were closed, inflexible, vertically integrated products, newer products are complex systems that combine proprietary hardware, proprietary software and specialized components, that adhere to a growing number of standards. Roughly speaking, we can distinguish between AMR hardware, components, functional AMR software, operational or non-functional AMR software, and APIs.

Conceptual AMR / AGV Architecture

Off-the-Shelf Components – Motion, Sensors, PLC, Drives, engines, control…

The common denominator between all AMR hardware is that they have wheels, encoders, brakes, motors, batteries and sensors that interact with the robot software.

There are many vendors for these hardware parts and kits that are part of the AMR ecosystem, and a robot manufacturer can choose a component according to the exact functionality, environmental specifications and safety requirements that they need.

Flexible product architecture can even allow the manufacturer to select the optimal component per specific customer requirements without needing to invest in significant development.

Functional AMR Software

This is what’s in charge of the robot being able to perform its task. For example – in a robot that’s supposed to scan for empty carts and take them back to an assembly line, functional software includes the scanning and visual processing, the way the robot latches onto carts, and its ability to identify its location. Functional software can be proprietary or from 3rd parties.

Localization, Navigation, and Motion Planning

The fundamental requirement from an AGV/AMR is for it to know where it is and move along a prescribed path safely. In the simplest form of navigation, AGVs simply follow a magnetic strip or a painted line on the floor in a sterile environment.

At the advanced end, AMRs have complete freedom of movement between points on a map while avoiding obstacles and interacting with humans.

Robot localization, navigation and motion planning inside a busy warehouse, surrounded by humans, clutter, vehicles and machines, is complicated. Localization and navigation technologies are one of the most rapidly evolving (and some might say hyped) AMR technologies.

Innovation is happening both on the sensor side (LIDAR, cameras, UWB, 5G…) and on the software and algorithm side (SLAM, map-pattern-matching, triangulation) and eventually hardware with algorithms in ASIC.

As demand for automation grows, autonomy operators want to be able to adapt to changing needs and dynamic environments. Robots and robot paths are required to adapt to the environment, and not the other way around.

But is navigation so important that it is one of the capabilities based on which to classify AMRs?

We believe it isn’t.

Yes, navigation is important. In fact in some cases it is so important that manufacturers consider it a key differentiator.

But for other manufacturers navigation is just another functionality box that needs to be ticked; they treat navigation technology as a means to an end, wanting to be able to pick and choose the navigation technology that works best for a specific use case, just as they do with components.

They can choose from the numerous navigation technologies that exist, the one that ticks all their boxes.

The capability that is important in this case is the ability to easily integrate any navigation technology that helps developers meet their needs, or allows them to easily develop it themselves, if they so choose.

What enables this is a robot software development environment that contains libraries and APIs that allow them to choose to build or buy with the same ease.

Operational AMR software

AGVs/AMRs do not exist in a vacuum. Plants and warehouses contain robot fleets that need to be told what to do at any given time. What’s more, marching orders may change due to evolving needs and the optimal way to execute the task may alter based on changing environmental conditions.

Fleet and task management and path planning require communication, local or central decision making capabilities, and interfaces to other systems such as safety cameras, safety cages, doors, elevators, etc. What’s more, they need to convey information such as status, location, health and more to the humans in charge of them.

Fleet simulation is always a part of a big AMR automation project. 2D/3D simulation allows automation service providers to prepare the complete logic of the automation tasks. It features stress testing, scaling planning and general operation research KPIs.

Other operational software includes the tools used to deploy robots in a specific site by the automation integrator, monitoring tools, software version control, and more.

All these capabilities are not part of the AMR manufacturers core competencies. Quite the contrary – developing these capabilities takes time and effort and detracts them from their core tasks.

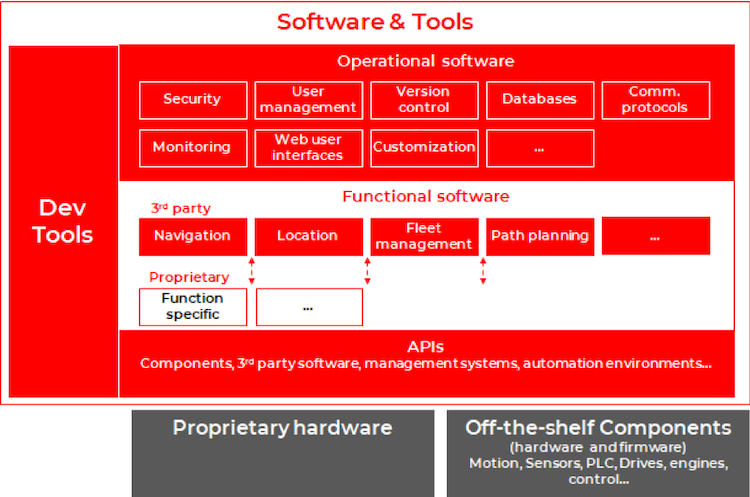

Robotic Engine Platforms – the missing link in the AMR technology landscape

The analysts and reporters looking at the market are missing an important thing. More than ever, the best way to compare AMRs and AMR manufacturers is not the specific technology component they use, but their ability to:

- Develop a differentiated offering quickly

- Easily pick and choose components and 3rd party functionality to optimize the AMR for specific needs

- Deliver customize solutions

- Quickly and seamlessly integrate into an existing automation environment

- Support users with effective interfaces, data and tools

All these capabilities require heavy investment in operational or functional software that is not at the core functionality of an AMR. These include things like security, user management, testing, simulation, and more. They require a combination of development tools, libraries, off-the-shelf integrations, and open API.

The use of a combination of development tools and pre-developed assets, or a software development engine, is common practice in other industries.

A new category is emerging of a Robotics Engine Platform, specifically for AMR/AGV software development.

A robotics engine platform includes Autonomous Mobile Robot software development tools, such as an IDE, off-the-shelf functional and non-functional AMR software components and simple APIs.

The AGV/AMR manufacturer has complete flexibility within the platform to either choose off-the-shelf components or develop their own robot software with the tools provided.

Conceptual AMR / AGV Architecture using a Robotics Engine Platform

The use of a robotics engine platform by an AGV/AMR manufacturer is a clear indicator that they will be able to deliver products much faster, and with more flexibility and customization. What’s more, their ability to focus on their core competencies may indicate better products.

ROS (Robot operating system) contains parts of these tools. MOV.AI is an example of a full blown Robotics Engine Platform that allows fast and flexible software development for Autonomous Mobile Robots.

Conclusion

The requirements from goods movement vehicles in manufacturing and warehouses are changing. The growing demand for scalable, flexible, tailored solutions combined with a crowded market requires a different AMR software development approach.

A critical enabler of competing in this market is using a Robotics Engine Platform to meet time to market, functional requirements and non-functional requirements. This important piece is the missing link in AGV/AMR technology analysis.

—

About MOV.AI

MOV.AI provides autonomous mobile robot (AMR) manufacturers and integrators with the software tools they need to create great robots quickly, allowing users to benefit from automation products that are as flexible as the age we live in.

Born out of an unmet need, MOV.AI is a Robotics Engine Platform based on ROS and packaged in an intuitive web-based interface. It contains everything needed to build, deploy and operate intelligent robots. MOV.AI completely changes the way Autonomous Mobile Robots are developed, in terms of time to market, cost and flexibility.

—

Article contributed by Limor Schweitzer, CTO and founder of MOV.AI.

Promoted

Thank You for this amzaing blog I really learned From It to meet India’s best Control and Automation Manufacturer Visit our Website fdhjs,fdhlvjkfdvj