What is design for additive manufacturing and why is it important?

Additive manufacturing, in addition to changing the way that a product reaches the consumer, also changes its form and function. Additive manufacturing breaks the barriers imposed by traditional techniques.

As 3D printing continues to revolutionize the product creation process in terms of design, its role in supply chain optimization and business strategy cannot be ignored.

Design for additive manufacturing requires skill and knowledge, so let’s look at what it means and why it’s important.

What is design for additive manufacturing?

If you’ve ever read about design engineering, you’re likely familiar with design for manufacturing (DFM) and design for assembly (DFA).

DFM helps the engineer optimize the use of manufacturing parts with an aim to minimize costs. It accomplishes this by identifying issues during the designing phase itself, so they don’t cause troubles later in the manufacturing process.

DFA also aims to minimize costs. However, it does so by introducing ease of assembly during the earlier phase of design. For instance, think of fasteners required to connect two parts. Fasteners, on average, account for 5% of materials cost but still contribute up to a massive 70% of labor cost.

These are the underlying considerations that form the basis for DFM and DFA. Fortunately, we have design for additive manufacturing (DfAM) that puts both these philosophies in the back seat.

Think about it – would you build a part that needs over 100 pieces if you could just 3D print one and bypass the assembly stage entirely? 3D printing reduces and often eliminates the need to assemble since all parts are already printed in their position.

For instance, let’s consider NASA’s 3D-printed rocket fuel injector shown in the image below. Using traditional methods, this injector could have required assembling 200+ parts. NASA’s 3D-printed injector, however, was only two parts!

What does DfAM do for us?

Many misunderstand DfAM’s potential thinking that the technology is only good for prototyping. 3D printing enables designers to achieve more with DfAM, but they need to change their drawing approach. It takes some experience to draw in a manner that works best with Additive Manufacturing.

Put differently, it’s essential to understand DfAM’s logic to leverage its potential. Therefore, it’s important to involve experts who can offer advice and help figure out solutions. Following are some things DfAM can do for your 3D models.

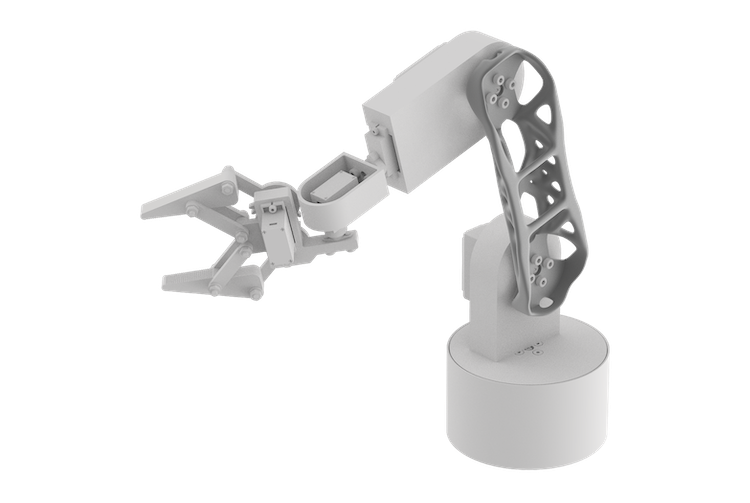

1. Topological optimization

A topological optimization software transforms your 3D model and whittles the material in it to give you the most efficient design. It doesn’t put any weight on traditional techniques, aesthetics, or any other constraints that are usually a part of the design.

In its most basic form, it will identify the material you need for developing a load path once you define a constraint and loading system. However, they can be quite a challenge for traditional manufacturing techniques.

2. Optimizing the structure

You may be overwhelmed by the choices of material you have for the project. While it’s certainly important to identify a proper material for your mechanical part, be sure not to overlook the design.

You can provide strength to the material you chose through tweaks and design features like lattice structures. Lattice structures offer excellent strength, are multifunctional, and have low mass mechanical properties. You’ll find them in parts used in the biomedical as well as aerospace industries.

3. Custom designs

Making design adjustments each time your client demands an adjustment is time-consuming. Plus, it’s economically unviable to keep pace with customization preferences of all clients since it involves incurring significant expenses.

However, additive manufacturing offers a solution here. Since your designs are saved in a 3D file that you can print as required, it makes edits simpler and saves a lot of time. It allows you to meet client’s needs by making quick customizations based on their demands.

Now that it’s been established what DfAM is and what it can do for you, let’s talk about why it’s important.

Importance of design for additive manufacturing (DfAM)

As additive manufacturing continues to evolve, its importance is starting to dominate the minds of designers and engineers. Let’s talk about a few points of importance of DfAM.

1. Reduced wastage

3D printing offers fresh design possibilities to engineers, allowing them to incorporate lighter parts through optimal material distribution, which translates to significant savings.

A topological optimization software makes this possible, along with tools such as lattice structures and generative design. Topology optimization uses mathematical calculations to identify the ideal shape for your part. This helps shed extra material while still maintaining the part’s structural integrity.

Generative design, topological optimization software, and 3D printing have been in use in giant manufacturing facilities such as GM and Siemens. GM, specifically, uses the technology to minimize the vehicle’s weight by navigating through several material distribution options within the component’s design.

2. Allows use of fewer supports

One of the most prominent benefits of design for additive manufacturing is part orientation. Appropriately choosing part orientation while still in the designing phase helps minimize printing as well as post-processing time, and also reduces the requirement for supports.

Granted, support structures are integral to complex 3D-printed parts. However, designing a part with a minimum number of supports simplifies post-processing and also saves considerable material and time.

Now, there’s no one formula that can reduce the support requirement for a part. Nevertheless, if you design the part carefully, it can be optimized and orientated such that it can carry itself without requiring a lot of support structures.

As automation begins to become mainstream, it will likely have an impact on the additive manufacturing industry. We can expect to see additive manufacturing software that can automatically generate part orientation and supports soon.

3. Facilitates minimizing of assembly time

Another very welcome benefit of additive manufacturing is part consolidation. Traditional methods required that all parts be manufactured separately and then assembled into one final part. However, additive manufacturing makes this process simpler.

You can print the full final part directly with 3D printing by integrating all the smaller components into one custom part when you’re designing it. This means the assembly process, if any is required, will become far simpler.

When you print a consolidated part, you’re also doing away with the hassle of having to procure and store those additional spare parts, which means you’ll also save up on maintenance and inventory costs.

4. Allows creation of complex parts with better functionality

Additive manufacturing removes the bottlenecks faced by traditional methods and helps designers create very complex parts that have excellent functionalities.

Consider an injection mold designed using a traditional method. In such a part, the cooling channels are generally straight, which means the molded part’s cooling will be rather slow and inconsistent.

3D printing helps remedy this by allowing us the print cooling channels that are designed with curved shapes, thereby allowing homogeneous transfer of heat.

5. Low-cost design iterations

3D printing facilitates quick, multiple edits without costing you a dime, which means you can customize all you want without spending a whole lot of time or money. The process is also significantly faster given that additive manufacturing can create parts using digital files.

Mass customization empowers all industries including medical and consumer goods. As an example, take the medical industry where mass customization is already in use for 3D-printing devices based on a patient’s specific needs. Some examples of such devices are prosthetics, braces, and hearing aids – that are made to perfectly fit the patient.

6. Promotes the use of innovative materials

Progress in materials research has resulted in some intriguing development of innovative materials. This has led to the development of unique 3D printing materials which would otherwise be difficult to mold, for instance, TPU filaments.

Another great example is high-performance thermoplastics that can be used in 3D printing, a material that was developed only for engineers. Often, such high-performance materials are suitable alternatives even for metal parts. They are lighter as well as more pocket-friendly.

This is how engineers can identify options that offer more preferable material properties when designing a component for 3D printing. Additionally, 3D printing can also help design parts that have properties of multiple materials (such as flexibility + rigidity), or integrated conductive as well as insulating properties.

Future of DfAM

Many designers are currently held back because of the conventions of older techniques. It’s critical that they begin to develop fresh approaches for additive manufacturing as the technology starts to mature.

Educational institutions and corporations, therefore, are central to the furtherance of DfAM-related skills and should consider developing training programs that will help the participants.

Although, progress is already being made in this area. For instance, UK’s Loughborough University has already introduced a post-graduate level program for additive manufacturing.

As of now, it seems that a good portion of the additive manufacturing process will be automated in the future, right from optimizing the design to the simulation of the process and lattice structures.

In the end, a stronghold on additive manufacturing’s design considerations will introduce us to its actual potential, leading to redefining of most product development rules.

—

Image sources:

https://unsplash.com/photos/hfoIlAvHuPw

https://www.nasa.gov/exploration/systems/sls/multimedia/gallery/3d_printer_2.html

https://ntopology.com/topology-optimization-software/