Multi-purpose security inspection robots call for embedded systems with highly flexible configuration

The miniaturized, light, modular, and general-purpose security inspection robots in China have improved the intelligence level of inspections by DFI high-performance and fanless embedded system.

Not limited to being deployed in dangerous fields such as substations, multi-purpose security inspection robots must be suitable for inspection needs in parks, communities, schools, factories, stations, and other places where visibility is needed.

A Chinese company, established in 2013 and one of the world’s first robotics companies to engage in autonomous mobile technology research and development and application exploration, once owned more than 70% of the market share of independent positioning and navigation modules in China, specializing in commercial cleaning robots such as unmanned automatic sweepers.

With specific applicability, excellent cleaning capabilities, mature and stable product performance, and perfect customer service, it has more than 1,000 customers in 30 countries. It also has a total operating mileage of more than 100 million kilometers.

After the company launched the first generation of commercial cleaning robots in November 2014, it launched its security robot solutions in January 2016. This security robot adopts a lightweight design and is equipped with rich functions.

For example, the staff only needs to set the time, route, and inspection content in advance.

As a result, the inspection robot can conduct independent inspections 24 hours a day to detect and predict potential safety hazards in the surrounding environment. At the same time, the staff can remotely monitor, grasp environmental data in real-time, and enable unmanned control.

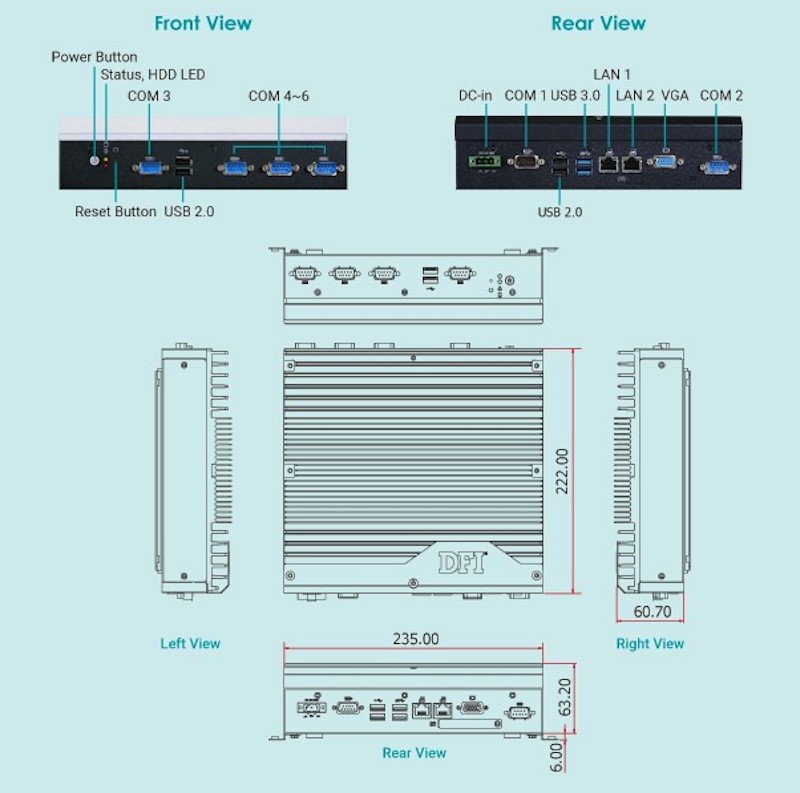

This multi-purpose security inspection robot uses DFI’s EC500-HD as its computing brain.

The reason for this selection is because of the low power consumption that can extend battery life, high performance for visual image analysis, and rich I/O interface required by the sensor, the solid aluminum structure, fanless cooling, and the high cost-effectiveness that is rarely met in rivals in the same type of products.

The subsequent EC500 product series have also inherited these advantages.

In addition to the technology, customers also benefit from DFI’s excellent business capabilities, technical support, and ability to fully grasp and immediately respond to customer needs.

It is worth noting that according to Intel’s IOTG product schedule, the fourth-generation Core processor (code-named Haswell) used by EC500-HD has ended its product life in the third season of 2019.

DFI has also provided a seamless upgrade guide to maintain effortless consistency and the least transition cost to ensure that existing customers can seamlessly migrate to the newer platform:

- 6th/7th Gen Intel Core Series: Compact / Upgraded for AI Computing

- 8th/9th Gen Intel Core Series: Compact / Upgraded for AI Computing

For more information, please feel free to contact us at dfi.com/contact