Trustworthy Substation Inspection Robot Requires Low Power, High Performance, and Multi-Interface Fanless Embedded System

A New Generation of Miniaturized, Lightweight, and Modular Wheeled Inspection Robot Powered by DFI Palm-sized Fanless Embedded System in China

Wheeled, substation, and intelligent inspection robots can effectively reduce labor intensity, substation operation, and maintenance costs. It can also improve inspection data quality and create a new substation inspection mode.

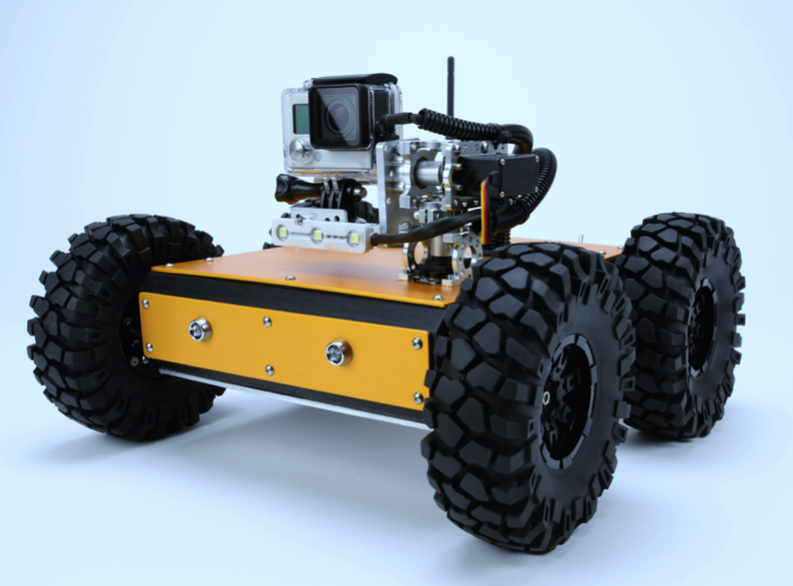

With low power consumption, high performance, complete I/O interface, and excellent technical support capabilities, DFI’s EC70A-SU assists Chinese customers to create a new generation of miniaturized, lightweight, and modular wheeled inspection robots. As a result, it improved the intellectual level of substation inspection.

Substation inspection robots mainly serve various substations, concentrated primarily on large-scale substations above 500kV. Therefore, they are used mainly to inspect substation equipment. They are divided into visible light inspections and infrared inspections.

The visual light inspection examines the appearance of the equipment, the status of the equipment from opening to closing, and the meter reading explicitly.

The infrared inspection is mainly used to measure the temperature, observe whether the equipment’s temperature is in the normal range, and analyze any abnormal temperature rise.

Early substation inspection robots belonged to Autonomous Guided Vehicles (AGVs) that needed to lay magnetic tracks in advance and moved forward or backward along the magnetic rails.

At each point that the AGVs are required to be stopped for the detection or turning and speed adjustment, an additional RFID tag needs to be buried next to the magnetic track.

The RFID tags contain information about the adjustment, such as detection, speed adjustment, turning, and so on. After the robot scans these tags, it performs corresponding actions.

With the rapid development of autonomous positioning and navigation technology, such as laser radar navigation and real-time simultaneous positioning and environmental map establishment (SLAM – Simultaneous Localization, and Mapping) algorithm technology, the environment does not need to be deployed in planning (such as rebuilding factories, laying track, and leveling the ground) for emerging autonomous mobile robot (AMR).

Autonomous Mobile Robots (AMR) are commonly used in different industrial fields because they do not need to be deployed in pre-planned environments (such as rebuilding factories, laying tracks, leveling the ground) like Autonomous Guided Vehicles (AGV). From warehousing to logistics to highly automated smart factories, they can be seen everywhere.

As a member of the AMR family, a small intelligent inspection robot, while maintaining the essential inspection functions of the robot, is smaller, lighter, and more convenient to deploy. As a result, it can be widely used in substations of various voltage levels.

And combined with ultra-high frequency wireless base stations and centralized management platform software, it can replace staff to complete equipment inspections in high-risk environments to meet the needs of unmanned substations.

A new generation of miniaturized, lightweight, and modular wheeled inspection robots that integrate autonomous navigation and positioning technology, non-contact detection technology, multi-sensor fusion, and background extensive data analysis can realize all-weather, multi-directional, and independent intelligence in substations.

As a result, inspection and monitoring can effectively reduce labor intensity and substation operation and maintenance costs, improve inspection data quality, and improve the intellectual level of substations.

A robot manufacturer established in 2002 in China specializes in the research and development of industrial technology products such as artificial intelligence, data monitoring, and intelligent grids, all while carrying out many intelligent inspections of robots and online monitoring of industrial equipment.

Based on the following reasons, DFI’s EC70A-SU was chosen as the heart and brain of its substation inspection robot to notice the business needs of inspection, meter reading, fire detection, and so on, instead of manual work.

Low power consumption: bringing longer cruise time, reducing battery charges, and extending battery life.

High performance: Applicable to visual image analysis and execute more complex and precise algorithms.

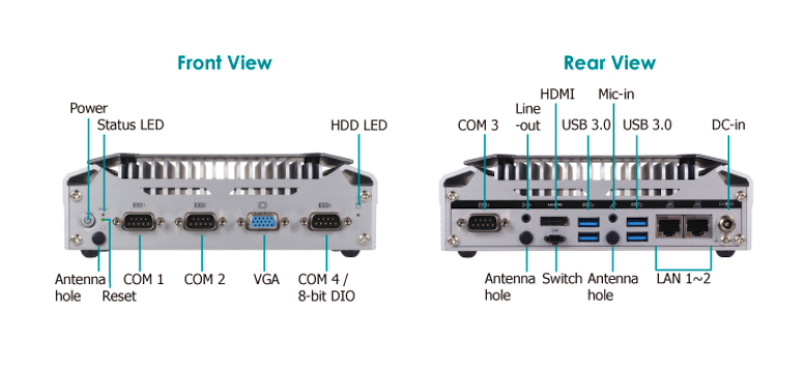

Comprehensive I/O interfaces: From connecting position sensors, inverters, servo motors to control robot movement, it fully meets all customers’ needs.

This robot can perform autonomous positioning and navigation using laser radar, inertial navigation, and visual road understanding technology, which effectively improve the accuracy of the robot during driving.

Instant SLAM technology solves the navigation and positioning map-matching problem caused by environmental changes.

In addition, the autonomous image recognition algorithm based on deep learning can flexibly apply regional focus, SIFT feature matching, and pattern recognition to achieve an excellent recognition success rate.

The robot can read the data of various meters, automatically record and judge while driving, and raise the alarm when needed. The robot automatically evaluates and recognizes the environment digitally, the error rate is less than 5 percent, and the success rate is over 95 percent.

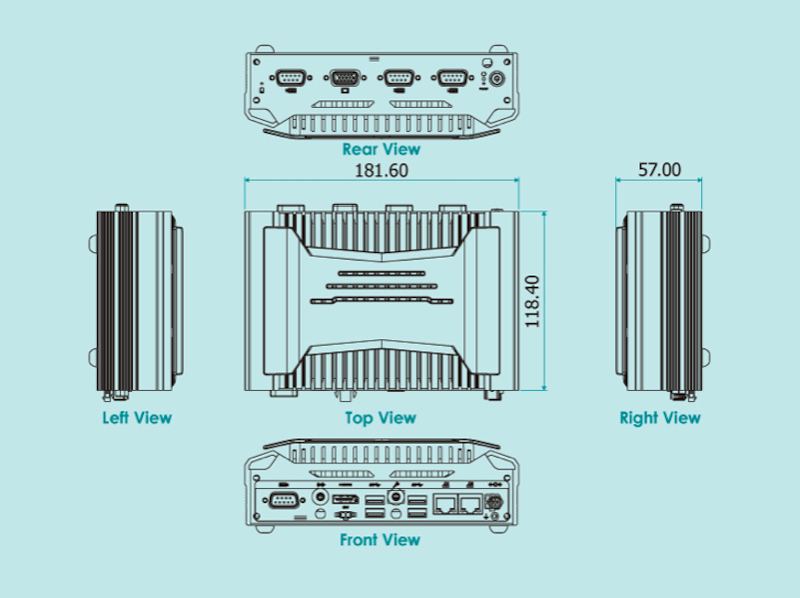

Due to the highly compact size of the EC70A-SU, the robot body has a small and exquisite design, which is convenient for manual handling and is also suitable for transportation by vehicles.

In addition to technology, customers also benefit from DFI’s excellent business promotion capabilities, technical support capabilities, and ability to grasp and respond to customers’ needs in real-time fully.

Another Chinese customer, established in 2007, is committed to supplying robots and artificial intelligence-related products and overall solutions.

With cutting-edge technologies in related fields as the core, it focuses on automatic robot control, navigation and positioning, machine learning, graphics, and image analysis, and developed various innovative robot products widely used in power, chemical, energy, and security railways, and other fields.

Its self-developed intelligent inspection robot takes the general robot technology as the core. It integrates multi-sensor fusion technology, intelligent image recognition and analysis technology, autonomous navigation and positioning technology, non-contact detection, and other technologies to achieve total autonomy efficiency in all-weather substations.

As a result, intelligent inspection and monitoring, while effectively reducing the labor intensity of employees, improve the automation and intelligence of operation and maintenance work. And provide innovative applications for substations with none or few people on duty.

The computing core of its miniature intelligent inspection robot also uses DFI’s EC70A-SU, which has a sturdy and durable structure. It comprises industrial-grade components inside and outside, supports 15~36V DC wide-voltage power input, and can operate stably at temperature ranges between -20°C to 60°C.

In addition, the onboard memory has a stronger shock resistance, which meets the durability of this miniaturized intelligent inspection robot during movement.

The EC70A-SU also provides six COM ports with galvanic isolation protection and supports RS-232/422/485 by adjusting the jumper, which improves customization flexibility.

Therefore, in addition to essential functions such as autonomous navigation, automatic charging, sound and light alarm, short message notification, and intelligent inspection, it is also convenient to customize for customers in different industries.

Furthermore, it can also integrate exclusive functions, such as infrared temperature measurement, three-phase temperature difference judgment, meter recognition, leak detection, defect detection, defect recognition, foreign body recognition, and other functions to become essential features of this miniaturized intelligent inspection robot.

Finally, the EC70A-SU supports a 15-year long-term supply of CPUs until the first quarter of 2030 and has a diversified selection of processor models, which uses EC70A-SU without worry.

Furthermore, the compact, lightweight, and powerful EC70A-SU is used as a miniaturized intelligent inspection robot with a computing brain, bringing higher value to the unmanned substation.

For more information, please feel free to contact us at dfi.com/contact