DFI provides ‘the most reliable brain and cerebellum’ for giant AGV in LCD panel factories

DFI’s AMR-dedicated AI computer enhances mobility and accuracy of mobile robots

The humble LCD panel was originally one of the Taiwanese government’s “Two Trillion & Twin Star” plan to develop its high-tech sectors. Now, it’s one of the country’s most significant symbols of electronics manufacturing.

With the trend of panel generation becoming larger and larger, in the production line of large-size panels, handling technology is also relatively important.

The introduction of robots can significantly reduce the factory’s labor demand and effectively reduce operating costs.

The giant automated guided vehicle (AGV) that transports tons of panels is essential, and it is a fundamental technical indicator in the robotics industry.

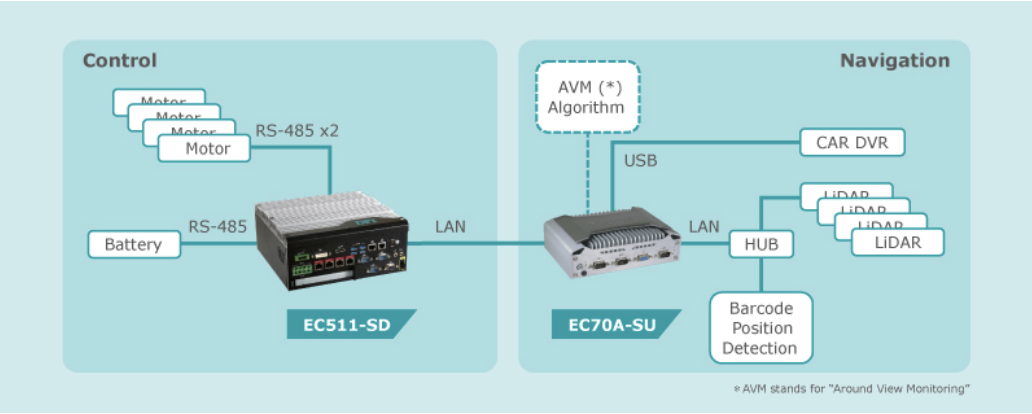

DFI combines the EC511-SD used to control large AGVs and the EC70A-SU used in full-time navigation to assist Taiwan’s major panel manufacturers in meeting their needs and achieving smart manufacturing.

Everything in the world starts small and then becomes bigger, and robots are inevitable. Giant uncrewed trucks used to carry bulky goods are indispensable and are necessary for LCD panel manufacturers.

Because of the unmatched operating complexity, its control and navigation system must be divided and ruled to ensure safe operations.

Over the past few decades, LCD technology has continued to develop, and production lines have naturally been updated.

Substrate sizes have continued to increase, and panel sizes have also continued to grow. In the 1980s, the maximum size was 8.4 inches; now, it can be 120 inches.

The operational challenges brought about by the rapid increase in size and weight have made the production line of LCD panels a key field for industrial automation applications.

From glass packing, glass unpacking, LCD packing, LCD unpacking, stacking glass panel, and the entire factory transmission equipment, the comprehensive introduction of robots solves the pain that comes from manual handling.

It also stabilizes quality and improves product yield, and has the 24-hour operation to improve economic benefits. It can also solve control problems and reduce personnel costs.

Automated guided vehicle (AGV) systems are now widely used in automated warehouse logistics systems, smart factories, smart manufacturing, and other fields.

One of Taiwan’s few large-scale LCD panel manufacturers adopted giant uncrewed trucks that can handle panels weighing more than 30 tons and meet transportation and storage needs across the factory.

Due to this giant uncrewed trunk’s complex structure and the need to continue the control management software used in the past, the computing brain responsible for “navigation” and the full-time “control” of the cerebellum must be divided and conquered and will facilitate subsequent software development.

As the computing brain navigates, it needs a more powerful computing performance, more diverse sensors, and durability to withstand harsh environments. And it also needs to be a smaller and more compact size. The cerebellum used for control must be connected to many COM ports of the mechanical components.

Not only must the number be sufficient, but also compatible with RS-232/422/485 and other protocols. It also must have galvanic isolation protection to meet the high voltage industry environment.

Two world-renowned LCD panel manufacturers in Taiwan have the industrial computer solution for control under evaluation but lack sufficient COM ports and galvanic isolation protection.

Therefore, several COM port adapter cables with USB interfaces must be connected, increasing the cost, making the cabling more complicated, and occupying a lot of internal space. This solution does not support remote out-of-band (OOB) management.

Once a failure causes a shutdown, you will have to go on-site to restart the system, and it isn’t easy to move manually, which seriously reduces the efficiency of the production line.

Because of this, DFI has customized an EC511-SD system to provide flexible expansion card design, four COM ports with galvanic isolation protection, and can also support RS-232/422/485 by adjusting the jumper to improve deployment flexibility.

The EC70A-SU used to run navigation software has a rugged and durable structure. Both the inside and outside are composed of industrial-grade components. It supports 15~36V DC wide-voltage power input and can operate stably at a temperature range of -20°C to 60°C.

The onboard memory has stronger shock resistance. The size of EC70A-SU is nearly 70 percent smaller than that of traditional industrial computers.

Its computing performance has also increased by more than 50 percent, which is enough to execute navigation software and continue the previous investment quickly. It is conducive to software development and retains the ability to upgrade more complex algorithms in the future.

EC511-SD uses the Q170 system chipset that corresponds to the Intel vPro platform and supports iAMT active management technology. When the control computer of the giant uncrewed truck encounters a failure, it can be restarted remotely out-of-band via the wireless network.

It also supports the 15-year long-term supply of CPUs until 2030. Hence, there is no need to worry about unsustainable stock-out issues. The return on investment is ensured so that the stable and reliable giant uncrewed truck can continue to work hard for the company for a long time.

Smart factories and flexible manufacturing under the industry 4.0 trend are the ultimate goals of various industries. Uncrewed trucks are an essential logistics tool to achieve this goal.

With the Internet of Things’ vigorous development, uncrewed guided vehicles can be combined with production equipment of different functions, link diversified production procedures, and expand various automation applications.

DFI’s solution considers the dual needs that provide the giant unmanned trucks of the LCD panel factory with the most reliable brain and cerebellum. It helps the Taiwan panel industry with an annual output value of more than one trillion Taiwan dollars.

For more information, please feel free to contact DFI at dfi.com/contact.