A Quick Guide to Vane Pumps: What They Are and How They Work

Vane pumps are one of those essential parts of automobiles or any device that uses high-pressure hydraulic pumps.

They’re essential and yet you may not be aware of their utility at all. They’re those perfectly well-engineered bits that are crucial to keeping things running perfectly.

Whether you need a new one for your car or a smaller device such as carbonators for soft drinks or espresso coffee machines, there are a few things you need to be on the lookout for.

The following is a quick guide to help you learn more about them and better understand their usage.

They Come in Different Sizes

Most vane pumps are massive and are included in major pieces of engineering such as planes or cars. The pumps are supercharging and essential in power steering, or even air conditioning in big HVAC systems.

Some vane pumps are also automatic transmission pumps which are helpful and used often to help operate massive pieces of machinery. Their influence is pretty much everywhere, and again, they’re sort of considered to be the secret heroes of any piece of engineering.

Also, as mentioned earlier, there are smaller mid-range pumps that are often included in different appliances.

Things to Consider

Vane pumps are built to withstand moderately viscous liquids, and they are especially good at handling low viscous substances such as propane gas, ammonia, solvents, fuel, alcohol, and so on.

In fact, finding the right vane pump can be a bit tricky, and there are a few factors that need to be taken into consideration. For example, some models have heating chambers that can handle solidifying liquids better and keep them at low viscosity to prevent them from gunking up in the pump.

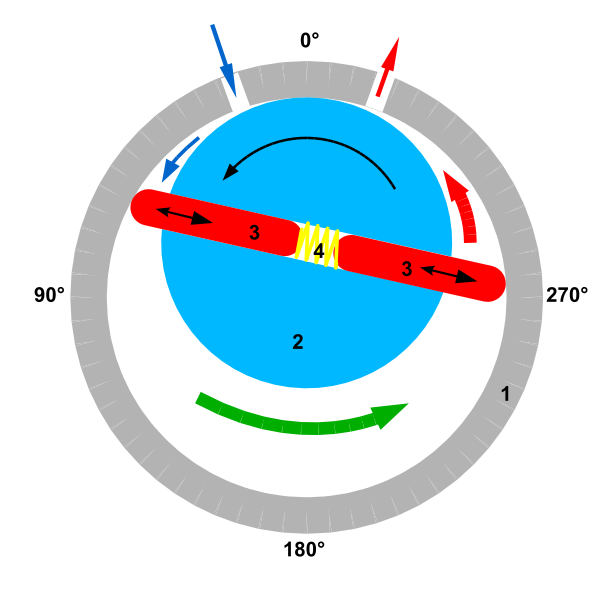

Meanwhile, reversible pumps are often used to help load and offload tankers, while doing the double duty work of ensuring that no product is left taking up room in hoses, thus damaging the larger piece of equipment irreparably.

So, perhaps that’s one thing you would like to take into consideration, depending on your needs. Also, there are some vane pumps that help by ensuring proper self-maintenance – some pumps lose efficacy as they wear out, while others can extend their life further by getting the rotor to ensure prolonged usage.

Pros and Cons

Pump vanes have a few clear advantages. Some of these include that they are a great option for thinner liquids, and the vane extension helps to ensure that the wear and tear are minimal.

It is also a more self-sufficient system in that it can run dry for short periods of time, so if push comes to shove, you do not have to ensure that it is being filled up with whatever liquid the machine needs all the time.

Vane pumps are also good as “vacuums” because they have powerful suctioning mechanisms, ensuring that viscous liquids don’t cause any blockage while the machine is being operated.

The main con working against vane pumps is that they are fairly complex and contain many parts, so they are definitely not for the layman to play around with or install on their own.

The answer as to whether vane pumps are absolutely necessary may be difficult to answer on your own, which is why looking for advice from an expert or external consultant may be helpful.

At the same time, you can look at different vendors and manufacturers, and make an assessment as to the correct model for your needs.