RoboDK, DIY-Robotics, and ATI release a ‘plug-and-play’ cell for robotic deburring

Robot software company RoboDK has partnered with DIY-Robotics and ATI Industrial Automation to release a combined application bundle for robotic deburring. The plug-and-play modular Robotic Deburring Cell can be integrated in just a few days. (See video below.)

With manufacturing industries changing rapidly, companies are increasingly turning to robotic automation to stay competitive. However, robot deployments have traditionally taken weeks or even months.

In February 2021, robot software company RoboDK partnered with DIY-Robotics and ATI Industrial Automation to create a pre-engineered, modular solution for robotic deburring that reduces deployment time considerably.

Why manufacturers need faster robot deployment

The use of robots is currently growing in various manufacturing industries. Robots allow companies to adapt to changes in the marketplace as they are more flexible than other forms of automation. A robot can be reprogrammed whenever the nature of its task changes and can even be redeployed to an entirely new task if needed.

A common constraint for companies looking to adopt robots is the time that they take to deploy. It can take weeks or even months to deploy a new robot into a manufacturing facility.

As well as being disruptive during the initial deployment, this also reduces the long-term flexibility of the robot cell as any changes to the robot’s task will further disrupt production.

A ‘modular, plug-and-play’ cell for robotic deburring

Deburring is a perfect task for a robot as it is dull for a human to perform and benefits greatly from the increased consistency that a robot provides.

The new plug-and-play Robotic Deburring Cell addresses this need for faster deployment by providing a completely self-contained system that can be deployed in a matter of days.

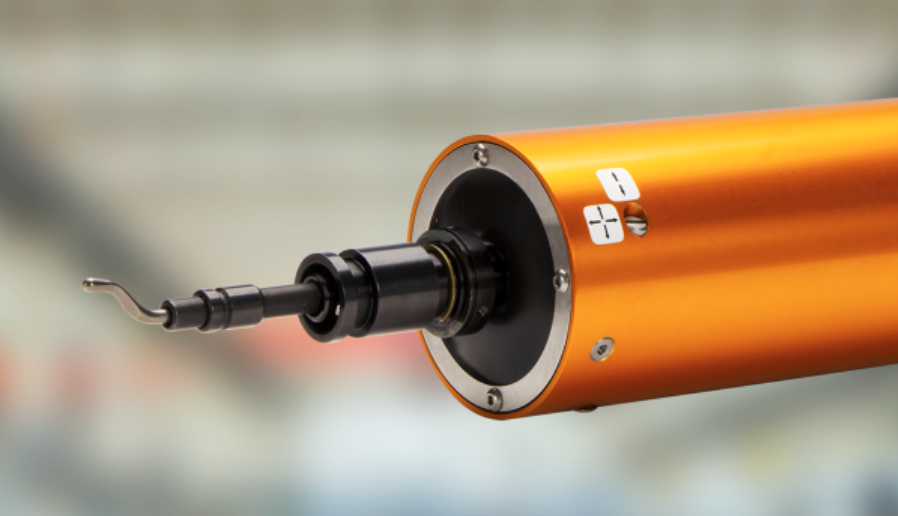

The solution is based around a pre-engineered robotic cell from DIY-Robotics. ATI Industrial Automation provides the cell’s Compliant Deburring tool. This versatile tool accounts for variations in part and feature location through its compliant tip and can be used for a wide range of deburring tasks.

Tim Burns, senior applications engineer for material removal products at ATI, says: “Tool, program, and robotic cell work hand in glove to make successful material removal applications more approachable to end-users.

“RoboDK makes the programming simple and easy for operators of all experience levels. DIY Robotics alleviates the challenge of integration by pre-packaging the right pieces for their cell.”

Deploying a deburring robot in just a few days

With conventional robot deployments, the sourcing process can be daunting for companies. All the various sensors, tooling, and accessories required for a robotic application mean that the list of components can quickly mount up.

Steve Blanchette, president of DIY-Robotics, says: “Robotics can appear complex to handle when it comes to coding languages and the complexity behind the technology.

“The main advantage of the Robotic Deburring Cell is its plug-and-play aspect. This bundle allows anyone, regardless of their robotics knowledge, to equip their factory with the latest industrial robotics technology.”

DIY-Robotics makes the sourcing process as simple as buying a desktop computer. Unlike many other robot suppliers, the company lists the price of its solutions on its website.

Once the order has been made, the robot cell ships within three weeks. It can be deployed in a few days for “turnkey solutions” or can be assembled by the user themselves, says the company.

Customizing the robot program with RoboDK

Programming functionality for the cell is provided by RoboDK, the offline programming solution that allows anyone to easily program their industrial robot even if they do not have robotic programming experience.

This gives an added level of flexibility to the Robotic Deburring Cell as the robot’s program can be created and updated through a simple graphical interface. RoboDK’s optimization tools for robot machining and deburring allow users to easily create error-free programs.

Albert Nubiola, RoboDK’s CEO, says: “DIY-Robotics’ Deburring Cell and the ATI’s Compliant Deburring Blade are now completely supported by the software. This is a great addition to RoboDK as it allows users to build a cell for deburring in just a few clicks.”

Future plans

The Robotic Deburring Cell is the first in a series of application-specific bundles that are being developed by this partnership. By leveraging their complimentary expertise, RoboDK, DIY-Robotics, and ATI Industrial Automation aim to make plug-and-play robotic cells much more accessible to manufacturing businesses.

Founded by Albert Nubiola in January 2015, RoboDK is a spin-off company from the CoRo laboratory at ETS University in Montreal, Canada.

RoboDK software is designed to bring powerful robotics simulation and programming capabilities to companies large and small and to coders and non-coders alike.

Today, it supports more than 500 robots from 50 manufacturers, including ABB, Fanuc, Kuka, Yaskawa, Stäubli, and Universal Robots.