Continental develops ‘quieter’ conveyor belts for flood protection projects in Tokyo

Continental has developed what it says are “quieter” conveyor belts for flood protection projects in Tokyo.

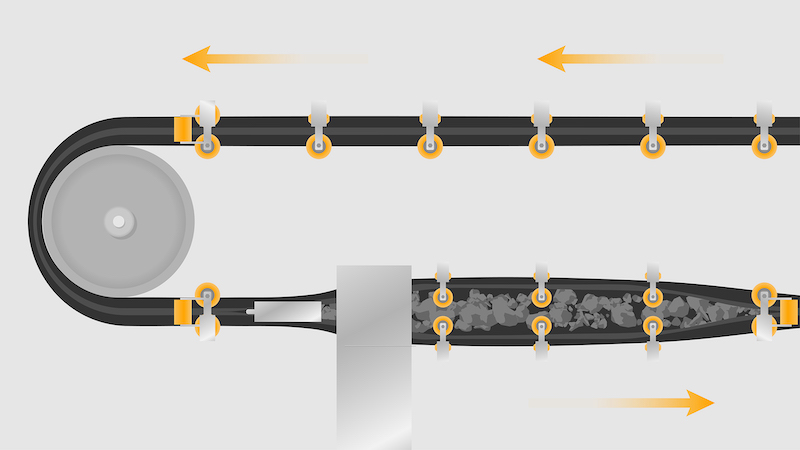

The company says its “Sicon” pouch conveyor belt transports bulk material safely and cleanly, with low noise and emissions, through residential districts of Japan’s capital.

The conveyor belt are being used in the construction of an underground catch basin for 150,000 cubic meters of water.

Continental says the solution “reduces noise pollution, dust emissions and traffic volumes” in residential areas.

Tokyo has long since grown into one of the largest metropolitan areas in the world – with almost 10 million inhabitants in the city and another 30 million in the surrounding area. Space for living and working is scarce.

This is also the case in Machida, a suburb southwest of Tokyo. Situated approximately 50 kilometers from the city center, it is home to around 450,000 people.

Huge residential areas stretch across the hilly area of the Tama Hills with the nearby River Tama.

For many years, the city has been regularly affected by torrential rain, high waters and flooding – with power outages, damage to infrastructure and potential risks for the people living there.

The underground catch basin on the Sakai River is intended to protect residents from flooding in the future. Completion is planned for 2024.

The pouch conveyor belts made by technology company Continental are being used in a flood prevention project in Machida, located in the western portion of Tokyo Metropolis.

Over the years, numerous rivers in Tokyo have been built over or regulated to create space to live. The risk of high waters and flooding is increasing as a result.

In order to mitigate this risk and protect inhabitants’ living space, the city is building an underground catch basin that can hold up to 150,000 cubic meters of water. Without it, this volume of water could flood residential areas, shut down public life and threaten the existence of many people.

Continental is contributing to this project and supplying a special conveyor belt that can be used to transport the material from the excavation of the collecting basin safely, cleanly and quietly from the construction site in the middle of a residential area.

Curve-negotiable in the tightest of spaces

To build the basin – 20 meters deep, 190 meters long and 90 meters wide – thousands of tons of earth and bulk material must first be excavated and transported out of the huge pit.

In December 2020, the installation of Sicon pouch conveyor belt with a length of more than 1,500 meters into the steel structure of the plant was finished. The installation, which is more than 750 meters long will start operation in a few weeks.

The 280 tons of material excavated every hour are transported on the conveyor belt at a speed of 1.4 seconds per meter across the residential area to a nearby main street, where it is discharged onto trucks.

Gabriele Hennig-Juman, from Continental sales for conveying solutions in the Asia-Pacific region, says: “The Sicon conveyor belt is a closed system from the feeding point to the discharging point. It can negotiate curves of up to 180 degrees, making it extremely flexible when routing the line and adaptable to any environment.

“Corners and edges can therefore be bypassed without additional transfer points – curve radii of less than one meter can be achieved.”

By using a snaking route, the belt conveyor is also able to overcome large differences in height in a very tight space.

A low-noise, no-dust and low-emission transport solution

The belt is manufactured in Northeim (Germany) and shipped from there to Japan. The contractors on site are the local Japanese-German joint venture of Continental “Bando-Scholtz” and Furukawa Industrial Machinery Systems, a specialist in Japan in steel construction and industrial equipment, which jointly coordinates and carries out all work for the end customer – the Tokyo Metropolitan.

An international service team from Continental and Bando Chemicals provides on-site support for the assembly and splicing of the belt and the commissioning of the system.

Masaaki Ogino, CEO of the Bando-Scholtz Corporation, says: “The pouch conveyor belt meets particularly demanding requirements in terms of cost-effectiveness and environmental compatibility. This reliable and clean transport solution takes into account both ecological aspects and preservation of the quality of life for local people.”

Without the conveyor system, countless trucks would have to drive through the residential area to the construction site over a period of months, resulting in a greater CO2 footprint and more noise pollution, as well as potentially increasing the risk of traffic accidents – particularly in the very restricted infrastructure of the residential area.

The no-noise and low-dust transportation of the excavation material using a pouch belt is therefore an effective alternative method of transport.