Asyril launches new control system for its robotic system

Asyril has launched Eye+, a new “intelligent control system” that manages the Asycube, hopper, vision and robot. (See video below.)

The company says the system allows the control of all components required for a modern and flexible assembly line.

With Eye+ Asycube users will be able to easily optimise the performance of their system without in-depth knowledge of machine vision and at a highly competitive cost. Eye+ also enables vision configuration and hand-eye calibration. This control system is easy to integrate and simple to use.

Asyril is a Swiss manufacturer of innovative 3-axis vibratory part flexible feeding systems.

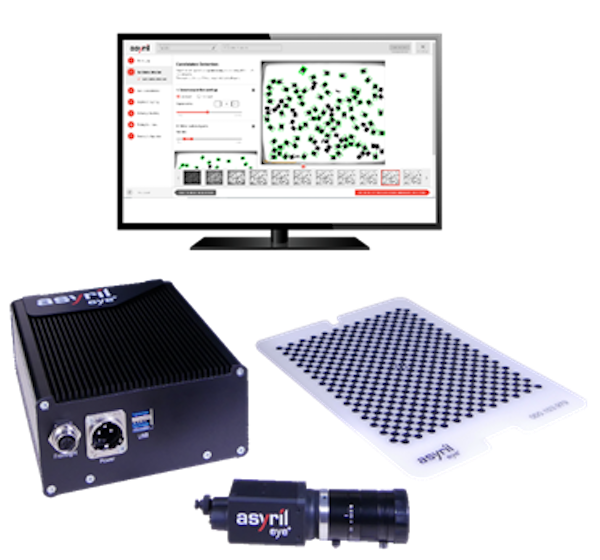

The company says Eye+ is the intelligence between Asycube and robot, it controls the hopper, Asycube, camera and the robot from a web based interface the Eye+ Studio.

From this interface, it also makes it easy to configure the vision, perform hand-eye calibration, change recipes and program new parts.

Consists of a compact controller, a high-resolution camera and a calibration plate, this plug and play system optimises the performance of your Asycube with integrated artificial intelligence based vision.

This system can be integrated with any size Asycube and any industrial robot and requires no knowledge of industrial vision, according to Asyril.

Flexible feeding helps manufacturers cope with the assembly, inspection, machining or kitting of products that are becoming more and more varied.

A typical flexible feeding system contains a hopper, a flexible feeder, a control system (camera) and a robot.

The camera takes images of the feeding platform, which in our case enables the intelligent control system EYE+ to communicate the coordinates of pickable parts to the robot.

In addition, Eye+ not only manages the vision but also the quantity of parts to be supplied, the feed rate, the hopper management and the platform operation.