Automating Performance Metrics: Start with Demand and Inventory Forecasting

By Mike Mills, Director, Business Consulting, Blue Ridge

2021 is the year when companies need earlier insights into new market opportunities, including what items consumers want, on what channel, how much they should stock, and how much they will pay for these products.

The ability to compete in new areas with this level of agility will be the key to unraveling chaos. As e-commerce continues to threaten the market with competitive products that are available nearly instantly, shifting consumer trends can make stocking shelves even more challenging.

Two-thirds of distributors, retailers, and manufacturers report that transportation, labor, and goods were rising more quickly than in previous years. Automation has become a full imperative; Covid has magnified the need.

Increased lead times due to transportation problems has risen, making it challenging to respond to demand swings as quickly as online distributors and retailers. While operation expenses continue to climb, distributors are not able to pass those on to customers. These higher costs coupled with the need to compete against e-commerce sites offering greater price transparency put pressure on operating margins.

Automation of performance metrics

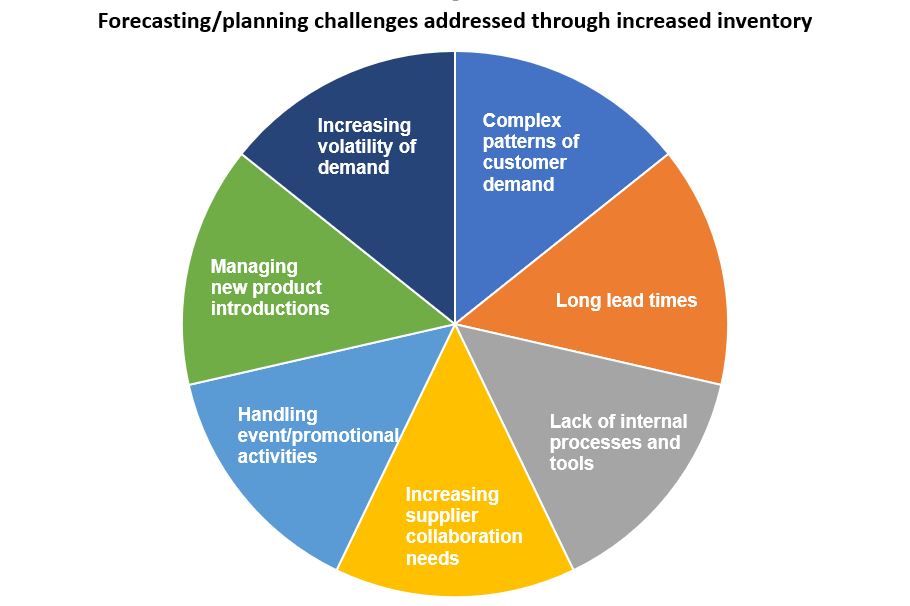

Companies tracking multiple performance metrics frequently find the current technology failed to provide actionable insights needed to understand the state of the businesses, customer metrics, and the financial and service implications of decision-making. Few have processes in place to combat current business trends, lacking the tools and processes to successfully plan and run the businesses.

Top wholesalers frequently share that the lack of automation keeps their company goals out of reach. Specifically, a lack of automation means poor management of slow-moving products and seasonal items. Those metrics are secondary to the automation value proposition of improving forecast accuracy.

Nearly two-thirds of all companies report that success based on customer service, inventory turns, and inventory dollars are top measurements enabled by automation technology.

Automating demand and inventory forecasting

Automation tools allow companies to get a better handle on demand and inventory forecasting to meet business objectives. Even companies that reported meeting inventory goals experienced an average growth in inventory of 3.66%, which by comparison was less than the average growth in sales.

Companies that automate and manage inventory better have fewer products on hand, freeing up cash to optimize other areas of the businesses – or even pay for the next big IT project.

Automating revenue improvement 2021

Revenue improvement must be the main goal in 2021, and better forecasting and inventory management accomplishes that goal. Companies need to evaluate current technology and measurement tools to discover where to improve and invest. When it comes to inventory, nearly half of all companies are able to offer different service levels based on the importance of items or clients. Others use tools that evaluate plans based on demand changes and reconcile sales, purchases, and other financials with budgets. Sadly, more than a quarter of companies fail to use any of these tools.

When it comes to inventory planning software, status quo or legacy systems fail to provide the information required. Still, too often the in-house solutions lack automation to achieve revenue improvement and must continue using outside analysis to better understand the business.

Better data and predictions

Companies with better data and predictions control the business most effectively. Helping companies focus on proactive planning, rather than reacting to economic trends is a critical shift. Consumer demand metrics and improved supply chain analytics can also offer insights where additional costs are incurred and managed.

Increasingly the number of wholesale distributors interested in machine learning techniques for forecasting and planning is expected to jump by more than 40% in 2021.

These data will continue to increase as real-world benefits of AI and machine learning prove beneficial in automating revenue improvement.

Those looking to improve revenue and better control costs understand that getting a better handle on inventory levels is essential. The use of supply chain planning software, coupled with price optimization, better demand forecasting, and integrated business-planning technology will improve service and revive margins.

Investing in data analysis tools and other technologies creates a distinct competitive advantage. Covid created economic uncertainties, chaos, and shifting consumer demand. Only real-time data analytics empower companies with agility, flexibility, and optimization.

About the author: Mike Mills is Director of Business Consulting at Blue Ridge. As a subject matter expert with 20+ years of supply chain expertise, Mike adds value to Blue Ridge by providing his expertise throughout the sales process. Mike treats each sale as an opportunity to challenge the status quo and show retailers and distributors how Blue Ridge solutions can have a demonstrable impact to their organization’s bottom line.