Important 2020 Trend: Price Alignment Automation

By Thomas R. Cutler

Automation solutions have been adapted and adjusted promoting the ease of setting and managing pricing boundaries for manufacturers.

When corporate objectives include rapidly and repeatedly adjusting prices at the most granular level, automation must be designed to alleviate the pain by using simple rules to derive prices.

Previously, most industrial business decision-makers feared an extensive implementation time, complexity, and significant costs for pricing technology.

New solutions overcome those concerns offering an automated pricing alignment technology which can be implemented cost-effectively and in just weeks.

Delivering significant improvements in revenue and margin by providing a clear, guided user experience (via insightful dashboards and comprehensive pricing science) means hundreds of manufacturing companies will benefit from this automation by Q4 2020.

It will ensure pricing execution remains aligned with strategic objectives in order to navigate the optimal margins.

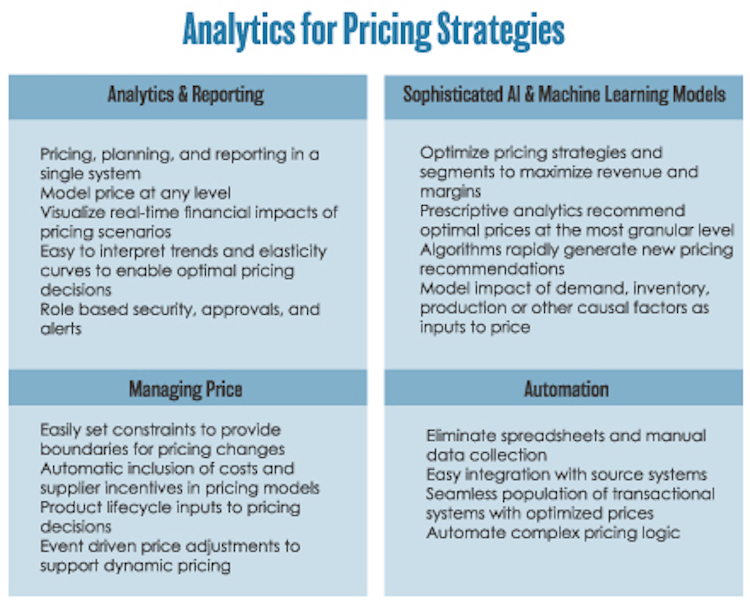

Automation must start with easy integration to source systems followed by seamless population of transactional systems with perfected prices. With those processes in place price alignment enables complex pricing logic automation.

Automation manufacturing pricing experts share best practices

Pricing experts, Dallas Crawford and Dan Barrett were asked to elaborate how manufacturers should analyze pricing needs using data analytics.

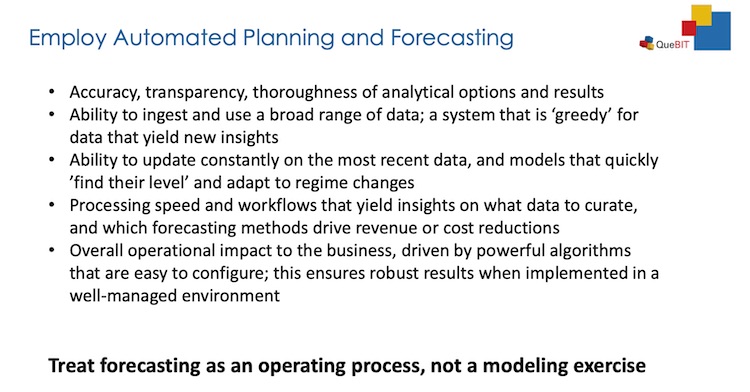

Crawford (pictured left) insisted that price aligning with data analytics can be done readily in real-time. The ability to concentrate on high and low volumes that fall outside a normal distribution of trend or seasonality can inform where margin opportunities exist.

Higher volume provides opportunities to adjust prices based on demand or to capture market share. Lower volume provides opportunities to analyze pricing, determining if market share is being lost or if the product’s lifecycle is near its end.

Barrett (pictured left) noted the best method to analyze and optimize customer pricing is to model the data and ensure that the analytics platform supports it at a very discrete level. Customer data by location or product SKUs allow for optimal delivery of unique pricing. Understanding and forecasting the customers’ pricing elasticity is key to determining the optimal price.

Pricing sensitivity

Crawford suggested that QueBIT PriceAlign’s Machine Learning models can be more adaptive than typical time series models in the pandemic environment.

Adding more qualitative and timely input variables (like fuel costs) allow the model to be more contextual and tolerant to the aberrant data collected during this unique event.

The pandemic gives manufacturing organizations, which embrace the technology, the opportunity to study and model the effects to be better prepared for future events. Shutdowns will potentially cause incomplete data; future training of Machine Learning models will have to deal with it.

Barrett is convinced while the pandemic is an important driver for price aligning, it remains just one factor impacting manufacturers on the demand and supply side.

By eliminating spreadsheets, price aligning improves the ability to rapidly adjust pricing to the most detailed levels and market conditions. In weeks, the automated pricing data ensures that manufacturers are able to visualize customer segments driven by variables that shape demand, such as demographics, allowing for more targeted and dynamic pricing adjustments.

Only through automated price alignment are mid-sized manufacturers able to raise pricing strategies to new levels of sophistication, achieving dynamic pricing based on a variety of factors, and understand price elasticity across different customers, products, or regions.

The use of Big Data automates and accelerates the most efficacious pricing model for small or mid-sized manufacturers. Barrett suggested that additional information often provides context and the more useful data elements can be incorporated into a more holistic process.

According to Crawford, manufacturers ingest Big Data in the form of invoices, quotes, cost information, demand, and supply which is not consumable by pricing professionals.

Advanced pricing systems can rapidly interface to Big Data, analyze it across dimensions (SKUs, customers, locations, etc.), and automate the iterative process of pricing. This gives manufacturers the ability to rapidly make pricing changes and actively manage the resulting performance of those changes.

This unique automation approach leverages predictive demand plans that utilize advanced analytics to drive accuracy and optimal prices. Only with pricing alignment automation will companies be able to properly respond to rapid pricing fluctuations during the pandemic.

Pricing Industry Experts:

Dallas Crawford is an Advanced Analytics Executive at QueBIT with over 10 years of experience helping customers leverage predictive analytics to make informed strategic decisions. Prior to QueBIT, he spent 7 years at IBM serving clients in the Distribution Sector and led multiple key Predictive Analytics and Reporting projects. Dallas graduated with an MBA from Florida A&M University in 2008.

Dan Barrett is an advanced analytics technical manager at QueBIT. Barrett served as Controller and CFO for a manufacturing organization for more than 12 years. He successfully led evaluations of Advanced Analytics solutions in hundreds of evaluation cycles with some the world’s leading manufacturing and retail organizations. He directed the development and field enablement of Distribution and Manufacturing Performance Management Solutions while at IBM and Cognos.

Author Profile: Thomas R. Cutler is the President and CEO of Fort Lauderdale, Florida-based, TR Cutler, Inc., celebrating its 21st year. Cutler is the founder of the Manufacturing Media Consortium including more than 8000 journalists, editors, and economists writing about trends in manufacturing, industry, material handling, and process improvement. Cutler authors more than 1000 feature articles annually regarding the manufacturing sector. More than 4500 industry leaders follow Cutler on Twitter daily at @ThomasRCutler. Contact Cutler at trcutler@trcutlerinc.com.