Rapid Growth of Autonomous Forklifts

By Thomas R. Cutler

Autonomously driven forklifts, whether in distribution centers, manufacturing, or some hybrid, are much more cost-effective than manned forklifts for extremely repetitive processes.

They can be integrated into continuous round-the-clock operations covering several shifts. Self-controlling these trucks can coordinate perfectly in terms of routing and speed. This enables material flows to maintain optimal levels and the energy consumption is kept to a minimum.

The additional benefit reported by facilities managers includes substantially less damage to shelving, loads, pallets, and other trucks, as they navigate more accurately and safely than manned forklifts.

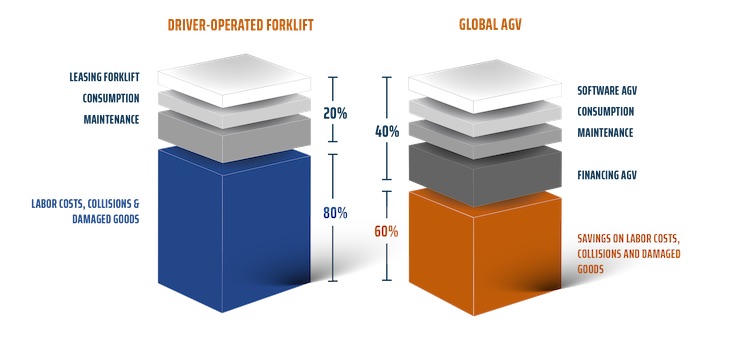

60 percent Savings on Day-to-Day Operations

Fewer than 2 percent of forklifts sold in North America are automated, yet there has never been a greater need for this technology. Many manufacturers are looking to automate material handling processes because it reduces the potential for COVID-19 exposure by reducing human contact.

COVID-19 has made autonomous forklifts an immediate reality for small footprint manufacturing facilities.

According to Nic Temple (pictured above) VP U.S. Sales at Global AGV, “Some of the key advantages of autonomous forklifts are critical during the pandemic.

A single unit offers a dynamic flexibility, scalability, and reliability that may allow compliance with safety requirements avoiding contamination. Automation reduces product damage and alleviates the ergonomic impact of repetitive, physically demanding tasks in today’s highly-complex manufacturing operations.”

Realistically an operation with just a few forklifts will replace a unit every 5-7 years. A manufacturer currently operating just a few units will exchange the next purchase in 2020 with an autonomous forklift to discover the true value that automation can bring to the operation. Implementing automation as a scalable solution will allow for an unbiased comparison of autonomous versus manual forklift operations.

Any manufacturer operating two or more forklifts currently, must consider replacing one unit with an autonomous forklift in 2020.

Autonomous forklifts provide automation which reduces movement costs per pallet and per case. Many manufacturers track these automation data as key performance indicators (KPIs).

These units seamlessly integrate alongside humans, often working collaboratively, unlocking significant productivity advances while also serving to address anticipated challenges resulting from the pandemic, the competition, and escalating operating costs.

Autonomous forklifts finally offer a straightforward interface solution: a simple point to point horizontal movement of pallets. Temple shared Global AGV is happy to work with small manufacturers who have never ventured in the mobile space and simply want to see the merits of a single autonomous forklift.

He added the breakthrough is selling an automated forklift as a product rather than a project. If the manufacturer wants a turnkey solution, a local network of system integrators is available.

Author Profile: Thomas R. Cutler is the President and CEO of Fort Lauderdale, Florida-based, TR Cutler, Inc., celebrating its 21st year. Cutler is the founder of the Manufacturing Media Consortium including more than 8000 journalists, editors, and economists writing about trends in manufacturing, industry, material handling, and process improvement. Cutler authors more than 1000 feature articles annually regarding the manufacturing sector. More than 4500 industry leaders follow Cutler on Twitter daily at @ThomasRCutler. Contact Cutler at trcutler@trcutlerinc.com.