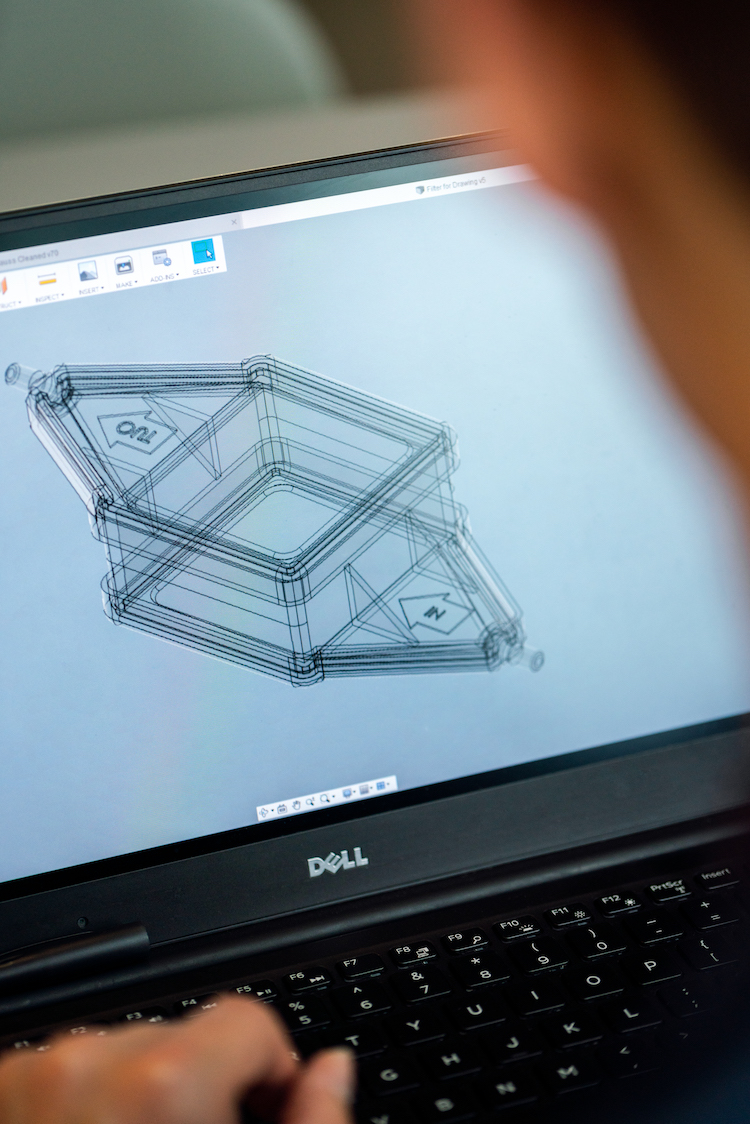

Since the 1980s, 3D Printing has become more and more common in the industry. Also known as additive manufacturing, it is basically the process of putting together a three-dimensional object from a computer-generated CAD or 3D model.

Multiple computer-controlled processes are involved. Among the most commonly observed is the layer-by-layer joining of materials and eventual solidification.

3D printing offers a lot of advantages. Among the most frequently cited benefit is its ability to expedite production.

It is faster than conventional manufacturing in the same way that a sports car is faster than a horse cart. Aside from being faster, the product can be of excellent quality.

Even with all the benefits that it brings, 3D printing has weaknesses and issues. We shed light to some of them here. We also discuss how such issues are being addressed or remedied.

Over extrusion

Among the most common problems faced by 3D printers is over extrusion. This happens when the computer-controlled machine uses more material or filament than needed.

This leads to excess material on the printed model and loss of valuable filament for future printouts. Very clearly, this is an efficiency issue that must be addressed if 3D printing is to continue as a viable business element.

Engineers and technicians solve or address over extrusion by simply editing the built-in extrusion multiplier. They do this by opening the slicer software and then making sure that the appropriate multiplier is chosen.

Warping

Generally, 3D printed models and items are said to be of more solid quality than conventionally manufactured ones. However, like any other process, 3D printing is also susceptible to machine errors. Another common issue is warping.

Warping happens when the base of the printed item starts to bend/fold upward, and it does not fall flat on the printing platform anymore.

This slightly elevates the item, resulting in the machine not being able to print on the appropriate spots. This leads to horizontal cracks, especially in the upper parts of the 3D-printed model or item.

The upward bending of the machine is often caused by premature cooling of the plastic material being used. To remedy this, engineers use a heated print platform. They also set the temperature to just below the plastic’s melting point.

String

Anyone who has worked with glue or any other quick-drying adhesive should understand how annoying “stringing” is. This problem occurs when excess molten material comes out of the nozzle, leaving “strings” in its trail as it moves from one area to another. This leads to having an item with unsightly strings that looks like cobwebs all over it.

Addressing this issue is quite straightforward. The technician can turn on the machine’s retraction feature. This means that the filament or plastic material is retracted back to the nozzle before moving from one printing area to the next. This effectively stops excess drips.

Even something as advantageous as 3D printing has issues. Technicians need to know how to address them so that they can continuously produce high-quality items on a much wider scale.

Main picture by ThisIsEngineering from Pexels

Promoted