Retail giant Gap improves supply chain with Kindred ‘Sort’ robots

Retail giant Gap says it has improved its supply chain output by implementing robots supplied by Kindred. (See video below.)

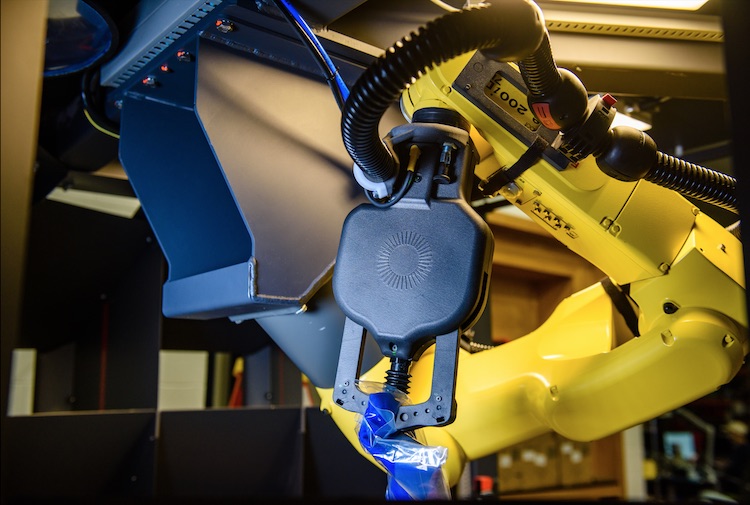

The system Kindred has supplied uses industrial robotic arms originally manufactured by Fanuc integrated into a solution called “Sort”.

Gap says that it has been “faced with an unprecedented surge in e-commerce and an extreme workforce disruption” which persuaded it that “now is the time for artificial intelligence and robotics solutions to solve complex fulfillment problems”.

Gap installed Kindred’s robotic picking technology in 2017 to accelerate merchandise picks within its facilities.

The AI-enabled system picked more than 13 million units of Gap merchandise between January 1 and April 30, 2020, at an average sorting speed of 335 units per hour, while maintaining 99.8 percent in uptime.

Gap purchased 73 additional Sort robots in its US distribution centers, to bring its total fleet to 106.

Once the additional systems are in operation, Gap will have paired the robot platform with all the automated primary sortation systems within its distribution network.

Marin Tchakarov, COO of Kindred, says: “Kindred’s modularity, price-per-pick and quick implementation model help retailers big and small embrace robotic automation.”

Kindred says Sort has “human-like capabilities” and separates multi-SKU (stock-keeping unit) batches into individual customer orders.

The company says the robot platform combines vision, grasping and manipulation capabilities to deliver “fast, accurate picking” at Gap distribution centers in Tennessee, California, New York and Ohio.