Interview: Startup Reflect developing new solution to ‘a real industrial problem’

Interview with George Papanikolopoulos, CEO of CASP, which is developing a software solution to what he describes as ‘a real industrial problem’

Reflect is one of the experiments that successfully passed to Phase II of the first Open Call in ESMERA, the EU agency that has a multimillion-euro budget to help robotic startups.

Being one of the 12 experiments that started in ESMERA in the summer of 2019, Reflect proved its concept to external evaluators and has been selected as one of the currently five final experiments in Phase II.

In addition to those five final experiments, one agricultural experiment among the three which are currently competing with each other will follow into that phase, as well.

Within that Phase II, the experiments will get additional funding for developing their product. Also, they receive mentoring and business support from the ESMERA consortium. The ESMERA consortium talked to George Papanikolopoulos, CEO of CASP about the Reflect project.

Congratulations for passing into the second phase of ESMERA. Does that mean, the development of your robotic solution is going well and as planned?

Yes, the first phase of ESMERA which was devoted in proof of concept has successfully come to an end. Moving on to the second phase, we will focus on the business activities related to our solution, as well as its optimization in terms of efficiency and robustness.

Can you briefly describe what robotics solution you are developing? What is Reflect about?

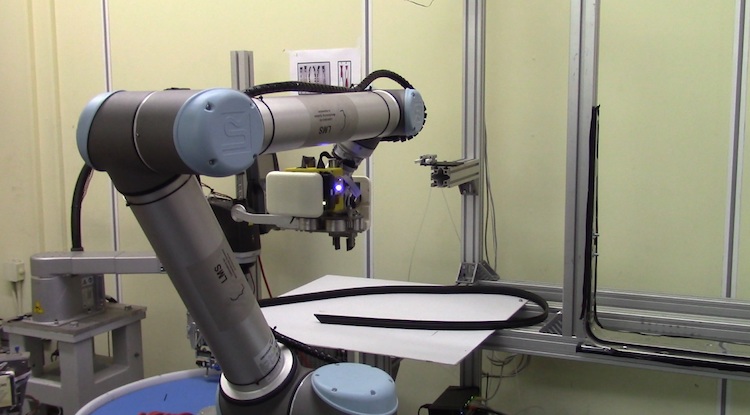

Reflect is dealing with an interesting challenge of contemporary industries which is the manipulation and assembly of linear non-rigid objects.

We are very happy to be given the chance by ESMERA to deal with a real industrial problem which is the assembly of rubber gaskets to dishwashers, so to prevent the water leakage between the door and the inner tube of the dishwasher.

Besides rubber gaskets, cables, wires, ropes, elastic tubes and beams and other objects frequently utilized in industries belong to this category of parts.

Given that the average wage in Europe is higher than the corresponding in competitive regions we think that Reflect solution may contribute to the improvement of the competitive advantage of European industry in the world markets.

With Reflect, you are solving a specific problem that a challenge provider handed in to ESMERA. What is that challenge about?

The specific problem that was handed to us involved the recognition and picking of pre-cut gaskets, as well as their manipulation and assembly to the inner tubes of a dishwasher.

This challenge has been dealt with: the development of a vision system capable of recognizing the gasket and detecting its location, a dexterous gripper capable of grasping the gasket from a surface and placing it inside the dishwasher slot, as well as the control framework for the exchange of data between the different entities of the solution (robot, sensors, actuators) and the coordination of the whole process.

Even though the complete process is executed by the robot, human aware robot motion and extra safety enhancements were added to the system allowing for the safe feeding of the cell with gaskets, as well as the inspection of the process results by human operators.

Are you in contact also with the challenge provider? Are they interested in already seeing the process of Reflect’s development?

Yes, we have been in contact with the challenge provider. The communication has been more active after the beginning of the second phase, as both of the sides are interested in the design and development of a solution which will comply with the requirements of a real industrial environment.

As I am given the chance, in this point I would like to thank our competence center, the Laboratory for Manufacturing Systems & Automation (LMS) in the University of Patras for encouraging and facilitating the communication between the challenge provider and us by organizing and coordinating meetings, as well as the consortium and the reviewers of our experiment who gave us the chance to pass to the second stage and continue our work.

You probably have a time plan for the next months, maybe years. When do you expect Reflect to go to market? What could be the major obstacles you might be facing?

Following the evaluation of the first phase, we have identified some actions in order to improve our solution. These actions include the redesign of the dexterous gripper to reduce the cycle time, as well as the development of a GUI in order to enable the user-friendly deployment of the cell.

We expect that within phase II we will manage to get close to a final product and that Reflect will go to market within Q1 2021. Of course, getting closer to the real operation conditions introduces difficulties, such as the robust support of the dishwasher under conditions similar to the ones of the existing conveyor system.

In any case, the developments of phase II will strongly affect the estimation for the Reflect launch, hence a more accurate prediction will be available at the end of this phase.

You have been developing Reflect in the context of ESMERA, a Horizon 2020 project from the European Commission. Can you describe the experience you are having being part of a European project, and what might be advantages or even disadvantages? Would you like to share some experiences from collaboration with the Competence Centres and how this has helped you overcome challenges and enhance your skills?

The experience of developing a solution within the context of ESMERA has been very positive, so far. The financial support from the European Commission has given us the opportunity to develop an innovative solution from scratch, something that otherwise would be very difficult, given the amount of the required initial investment.

Also, the Competence Centre has supported us during the development of the product providing equipment (robot, sensors), background knowledge and expertise on human-robot interaction robot programming, and robotic vision systems, as well as during the testing of the solution which was held in its premises.

We were really pleased to see their satisfaction after our demo was completed and we hope to share similar positive experiences within the second phase.

You probably have tried solving problems by innovative robotics solutions before. What made you participate in ESMERA in the first place?

Indeed, CASP is experienced in developing solution for innovative robotics solutions, as it has been involved in a number of EU funded robotics related projects. For example, Merging, Programs, Autorecon.

The ESMERA project offers a very attractive combination of funding and services both scientific and business, which leveraged our participation.

And what are your wishes and expectations for the rest of the project’s runtime?

We wish to use the additional funding, mentoring and business support to the highest extend, overcome the challenges which are introduced with the commercialization of our solution and reach a high “Market Readiness Level” via our development and business activities.

Main picture courtesy of WebUrbanist.com

George Papanikolopoulos, CEO of CASP, developer of the Reflect system, a project funded by ESMERA.